Constant temperature gas water heater and control method thereof

A technology of gas water heaters and water heaters, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as heat exchangers are easy to boil and gasify, affect product life, reduce temperature rise when water is stopped, and achieve a solution Long waiting time for hot water, improve the effect of rapid heating up, and reduce the effect of water supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

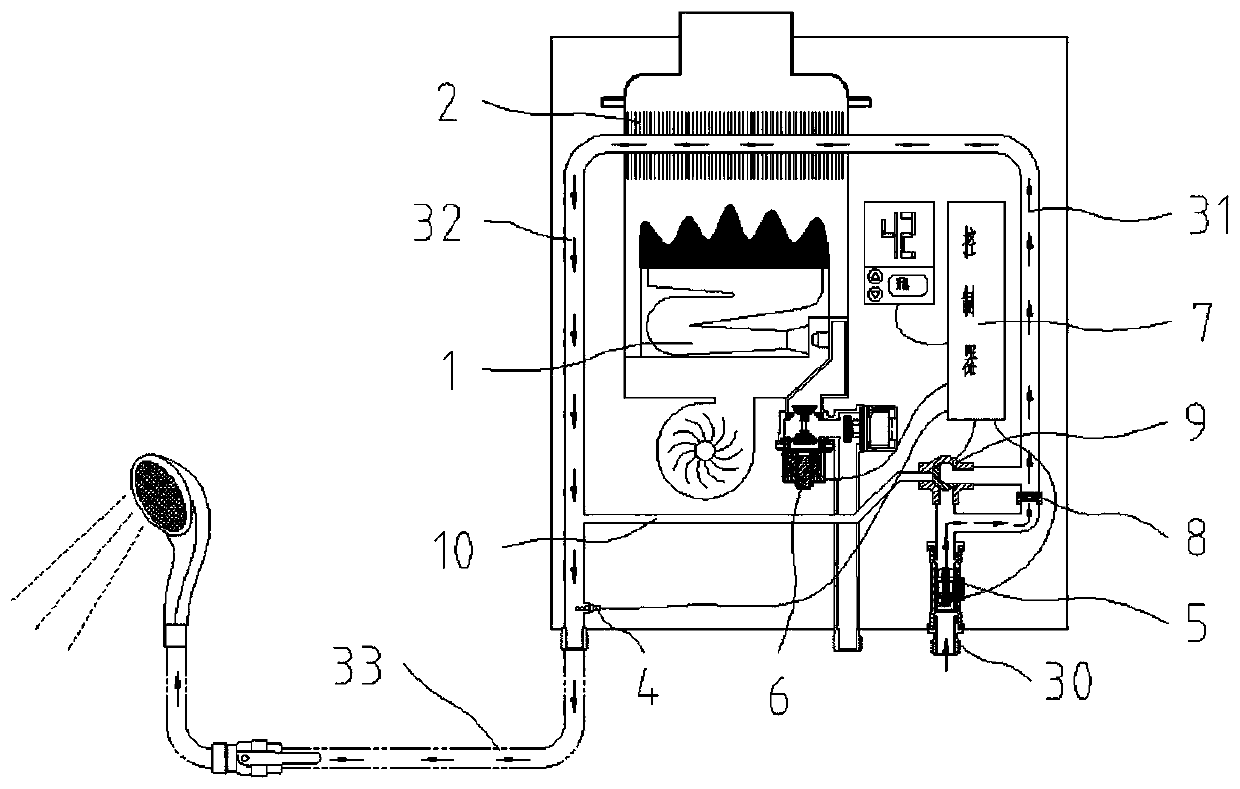

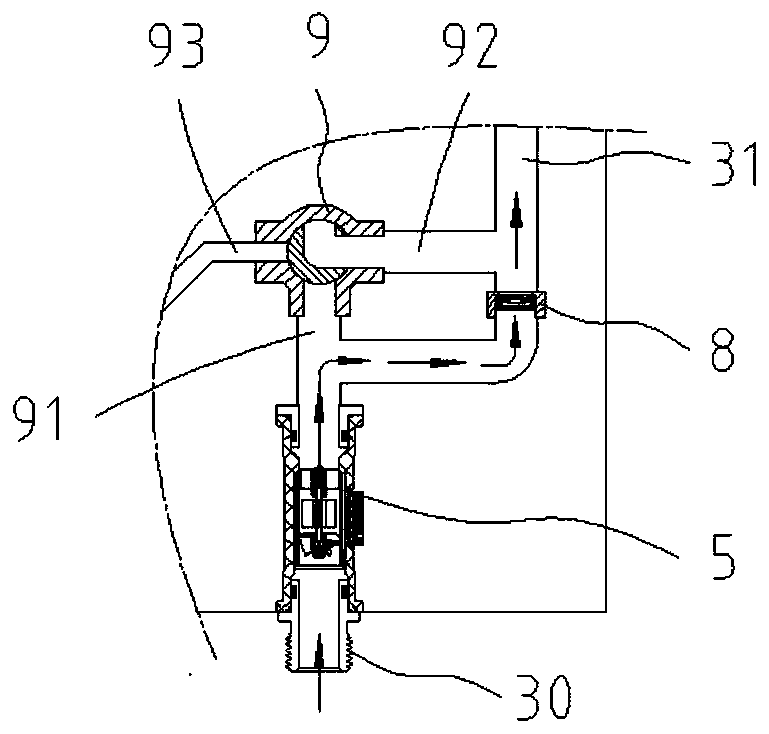

[0047] Such as Figure 1-2As shown, a constant temperature gas water heater in this embodiment includes a burner 1, a heat exchanger 2, a water inlet pipe 31, a water outlet pipe 32, a temperature detection device 4, a water flow detection device 5, a gas control valve 6, and a controller 7 , the flow stabilizer 8 and the water flow control valve 9, the two ends of the water inlet pipe 31 are communicated with the water inlet of the external water supply (i.e. tap water) and the heat exchanger 2 respectively, and one end of the water outlet pipe 32 is communicated with the water outlet of the heat exchanger 2, The other end communicates with the external hot water pipe 33 through the water outlet joint. The temperature detection device 4 is arranged on the water outlet pipe 32 and is electrically connected with the controller 7 for monitoring the water outlet temperature of the water outlet pipe 32 in real time. The water flow detecting device 5 is arranged on the water inlet...

Embodiment 2

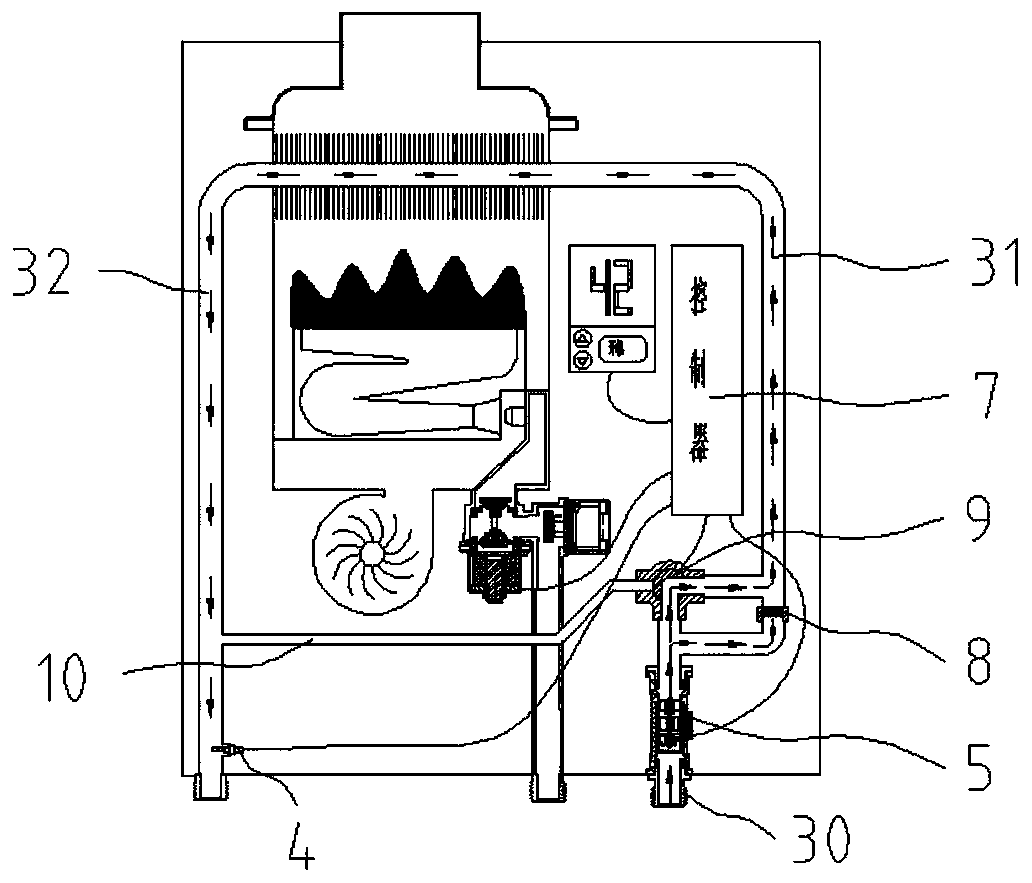

[0057] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the installation position of the water flow detection device 5 is different. Specifically, the water flow detection device 5 is arranged between the heat exchanger 2 and the junction of the flow stabilizer 8 and the first water outlet 92, so as to ensure that the water flow value detected by the water flow detection device 5 is used for flowing through the heat exchanger. The water flow rate of 2 can prevent the water supply pressure from being low when the water heater is in the mixed water position and start the ignition, effectively prevent the water stored in the heat exchanger 2 from boiling and vaporizing, and ensure the product life.

Embodiment 3

[0059] Such as Image 6 , a control method of a constant temperature gas water heater of the present embodiment, which applies the constant temperature gas water heater as described in embodiment 1 or 2, and the control method includes the steps of:

[0060] S3: Exit the bathing mode, switch the water heater to the mixed water position;

[0061] Specifically, the controller 7 is connected with a timing module. Exit the bathing mode after the water heater is turned off, the controller 7 controls the water flow control valve 9 to connect the second water outlet 93 and the water inlet 91, and disconnect the first water outlet 92 and the water inlet 91, so that the water heater is switched to the mixed water position , and at the same time, the timing module starts to record the time when the water heater is turned off.

[0062] S4: Continuously judge whether the water heater is in the program reset time t 复位 Turn on the ignition again, if so, go to the next step, if not, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com