Shield tail brush dynamic sealing pressure resistance test equipment

A dynamic sealing and pressure test technology, which is used in the testing of wear resistance, mechanical parts testing, machine/structural parts testing, etc. Problems such as unable to dynamically render

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

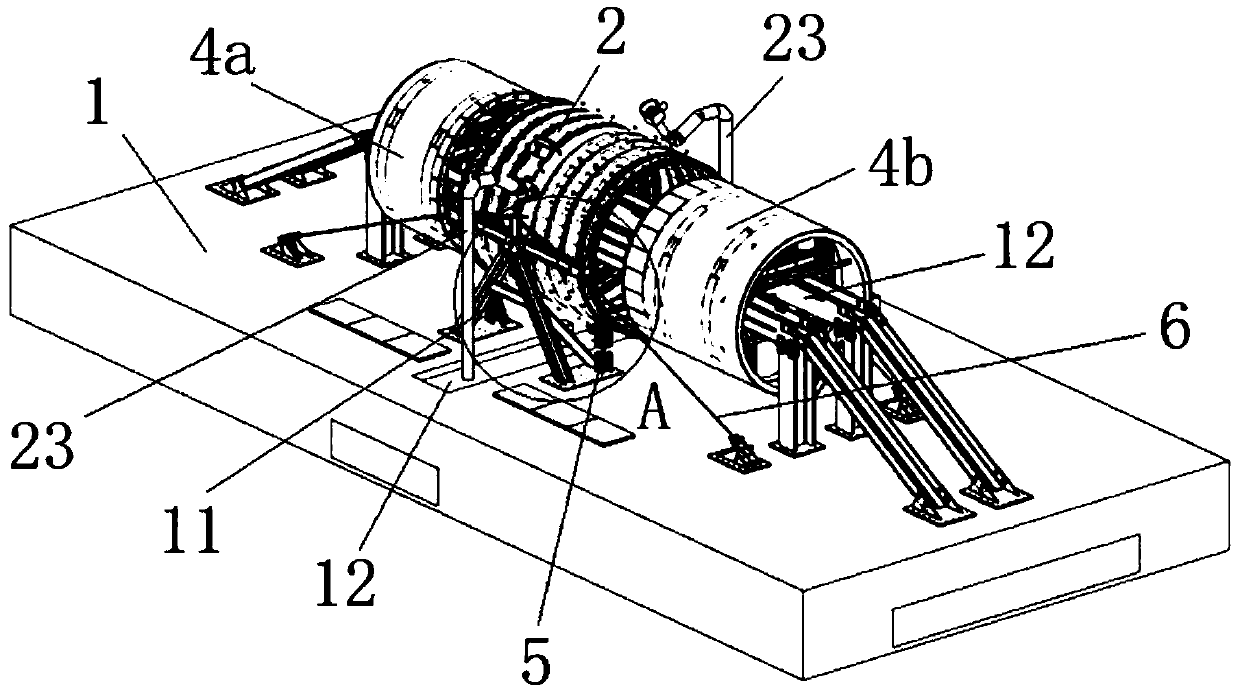

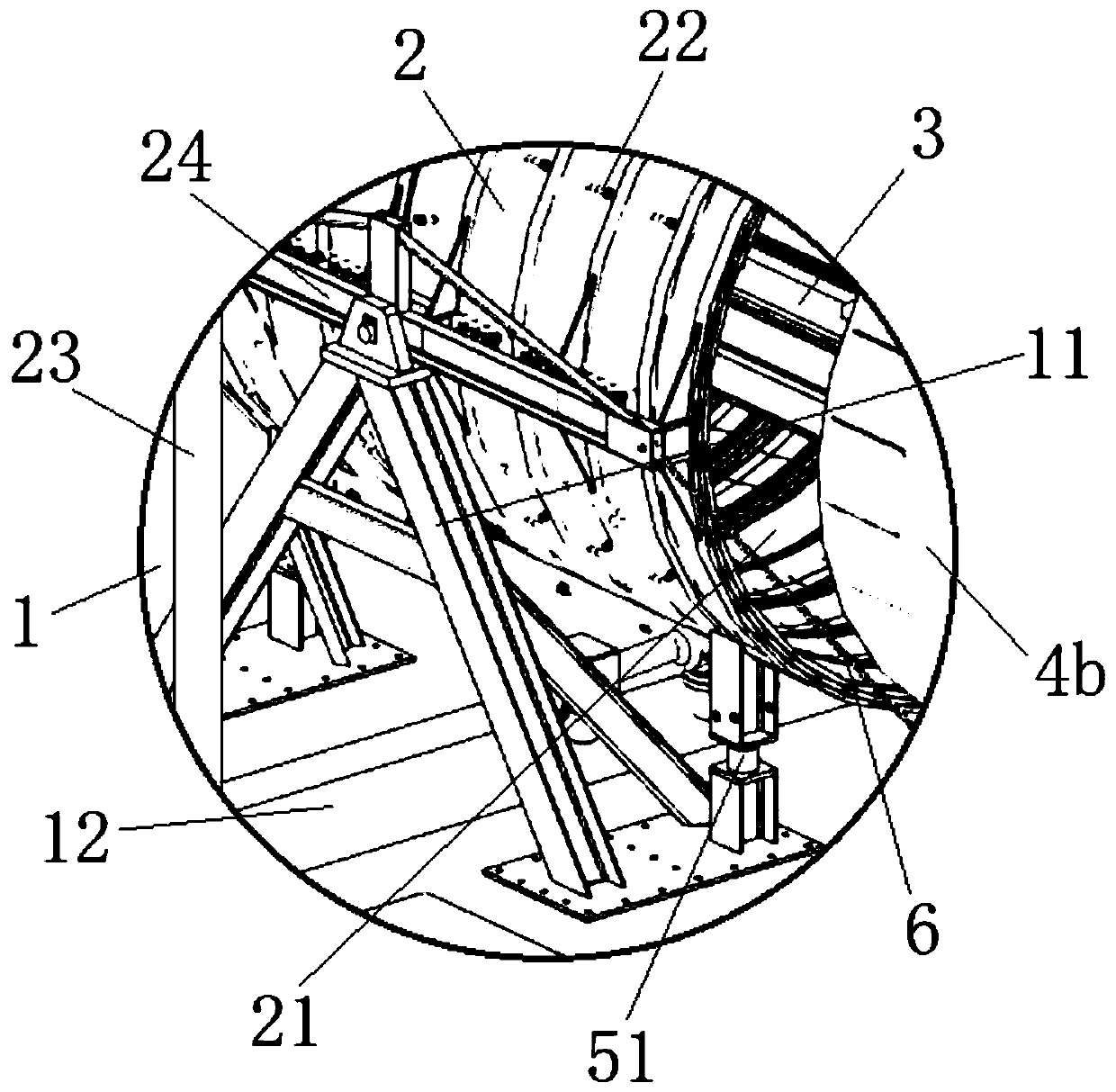

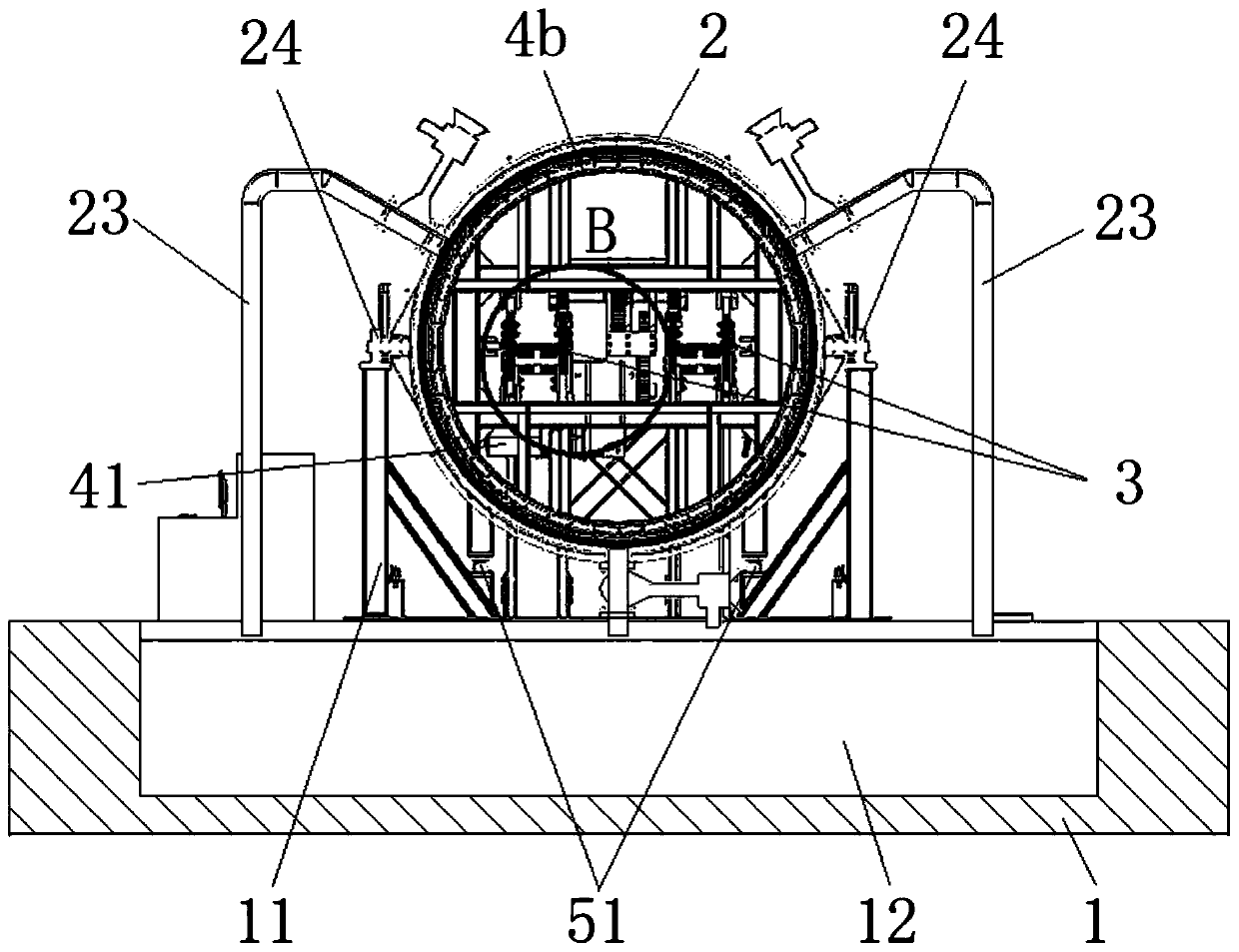

[0029] like figure 1 and figure 2 As shown, a shield tail brush dynamic seal pressure resistance test equipment of the present invention includes a base 1, a support frame 11 straddling the middle of the base 1, a simulated shield tail steel cylinder 2 pivotally connected above the support frame 11, The transmission track 3 horizontally passing through the axial hollow of the simulation shield tail steel cylinder 2 and the simulation segment 4a and self-sealing steel cylinder 4b that can move along the transmission track 3, the simulation segment 4a and the self-sealing steel cylinder 4b are separated on the The two sides of the simulated shield tail steel cylinder 2, the outer diameters of the simulated segment 4a and the self-sealing steel cylinder 4b are smaller than the inner diameter of the simulated shield tail steel cylinder 2, and the axes of both are the same as the axis of the simulated shield tail steel cylinder 2 when it is horizontal. line, the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com