Boiler furnace near-water-cooled wall reducing atmosphere test and combustion optimization adjustment system

A near-water-cooled wall and boiler furnace technology, applied in the control/regulation system, control combustion, color/spectral characteristic measurement, etc., can solve the problems of limited test timeliness, increased maintenance, limited adjustment methods, etc., to eliminate high-temperature corrosion problems, reduce reducing atmosphere, and realize the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

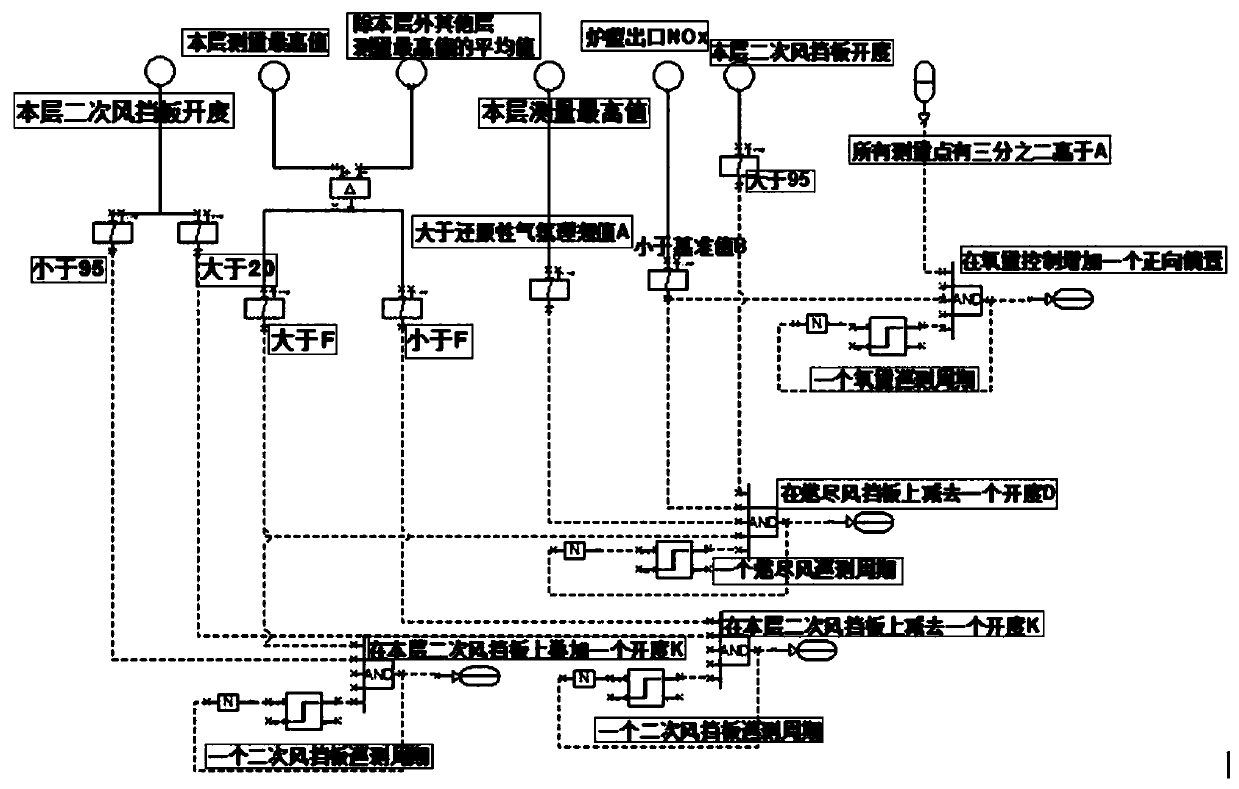

[0028] The technical scheme of the present invention is further described in conjunction with specific embodiments and accompanying drawings.

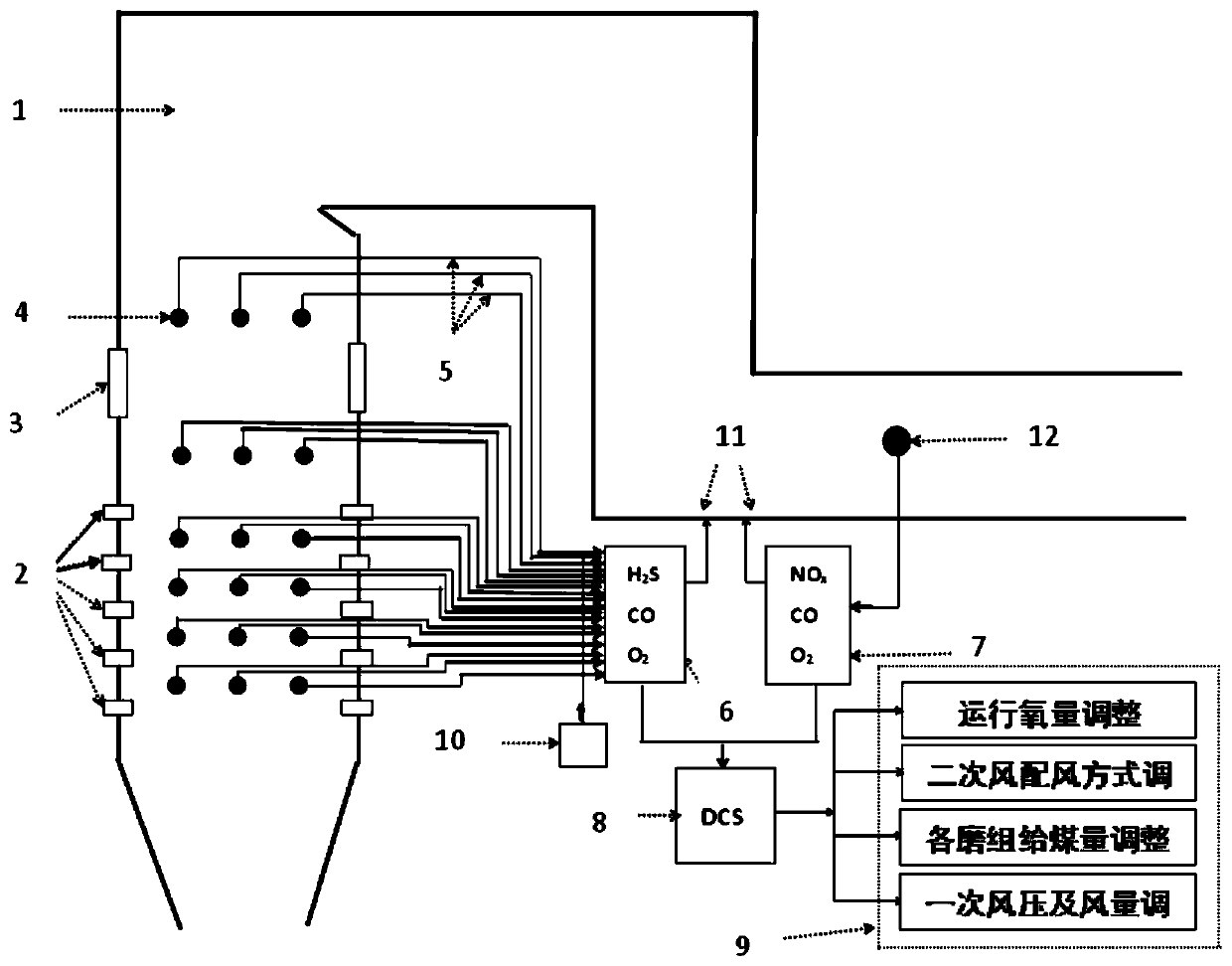

[0029] Such as figure 1 In this embodiment, the reducing atmosphere test and combustion patrol adjustment system near the water wall of the boiler furnace is mainly composed of a flue gas sampling point, a survey unit, a tail flue gas sampling and analysis system, a sampling control unit and a patrol unit.

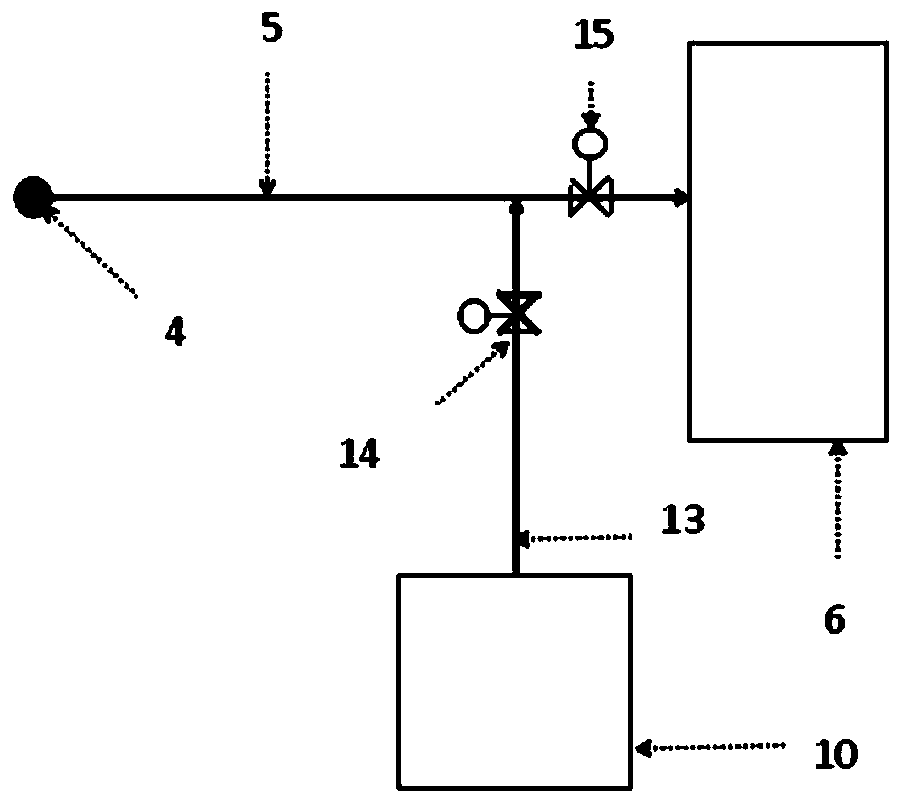

[0030]Install the flue gas sampling point (4) near the boiler water wall at the corresponding position of the boiler water wall. The measuring point is installed at the fin between the adjacent water wall pipes, and a sampling hole with a diameter of about 8 mm is removed at the fin, and then used The flue gas sampling pipe (5) leads to the reducing atmosphere analysis equipment (6) for analysis. For the boiler provided in this example with four-corner tangential arrangement of burners, the flue gas sampling points (4) near the wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap