Anchor Chain Observation Tool

A technology of tooling and anchor chains, which is applied in the field of ships, can solve the problems of the risk of falling into the water, the inability to retract the anchor chains, and the large angle of the anchor chains, etc., to achieve the effects of smooth retraction, simple structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

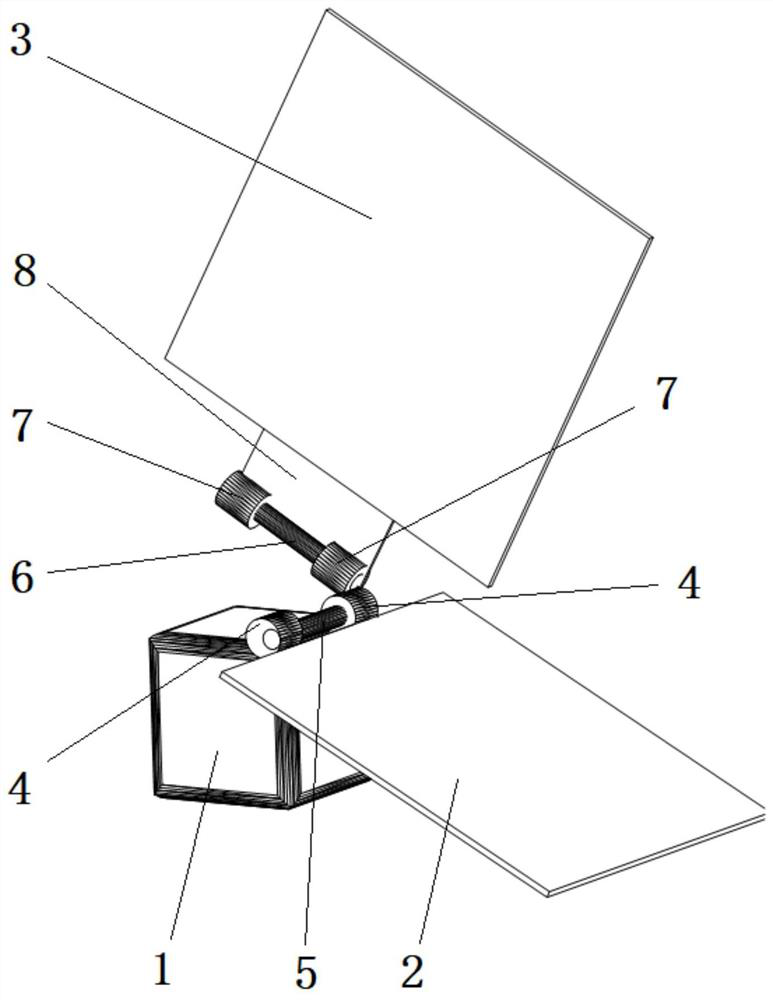

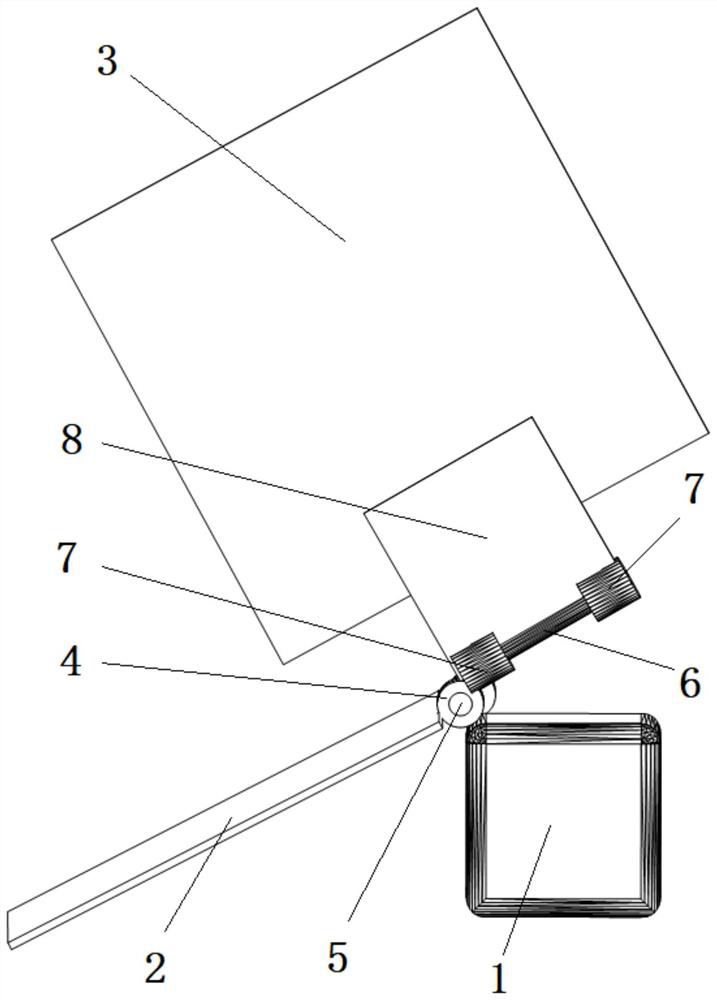

[0022] Such as figure 1 with 2 As shown, the mooring anchor chain observation tooling includes a magnetic suction device 1, a viewing mirror 2, and an observation mirror 3. The magnetic suction device 1 is welded and fixed with two first nuts 4, and the two first nuts 4 are threadedly connected. The first bolt 5, the viewfinder mirror surface 2 is fixed with the first bolt 5 and can rotate with the first bolt 5, the first nut 4 is fixedly connected with the second bolt 6, and the end of the second bolt 6 is connected with the first bolt 5. The first nut 4 is fixedly connected, the second bolt 6 is threaded with two second nuts 7, the observation mirror 3 is fixed with the second nut 7 and can rotate with the second nut 7, the The included angle between the viewing mirror 2 and the viewing mirror 3 is an acute angle, and the upper surface of the viewing mirror 2 is used for framing and reflecting to the front surface of the viewing mirror 3 . The included angle between the se...

Embodiment 2

[0027] On the basis of Embodiment 1, the second bolt 6 and the first nut 4 are fixedly connected through a universal adjustment mechanism (not shown in the figure), and the universal adjustment mechanism is a conventional structure in the field of mechanical structures, which can It is enough to realize universal adjustment and fixation, such as universal ball head structure, etc., by setting a universal adjustment mechanism, the observation mirror surface 3 is not limited to rotate with the second bolt 6 to adjust its angle relative to the viewfinder mirror surface 2, and can also make The observation mirror 3 is rotated and adjusted within the rotation range of the universal adjustment mechanism, which increases the adjustment range of the observation mirror 3 relative to the viewfinder mirror 2, makes the adjustment range more diverse, and is more conducive to correct and rapid adjustment of the observation mirror 3 and the viewfinder mirror 2 The relative angle between them...

Embodiment 3

[0029] On the basis of embodiment 1 or embodiment 2, lock nuts (not shown) are threaded on the first bolt 5 and the second bolt 6, when the viewfinder mirror 2 and the observation mirror 3 are adjusted , the lock nut can be rotated, so that the lock nut tightens the corresponding first nut 4 and the second nut 7, avoiding accidental rotation of the viewfinder mirror 2 and the observation mirror 3, ensuring the stability of the structure, and making the observation process go smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com