Centrally located linear actuators for driving displacers in a thermodynamic apparatus

A technology for linear actuators and thermal equipment, applied in lighting and heating equipment, mechanical equipment, irreversible cycle compressors, etc., to achieve the effect of less chance of failure, easy assembly, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

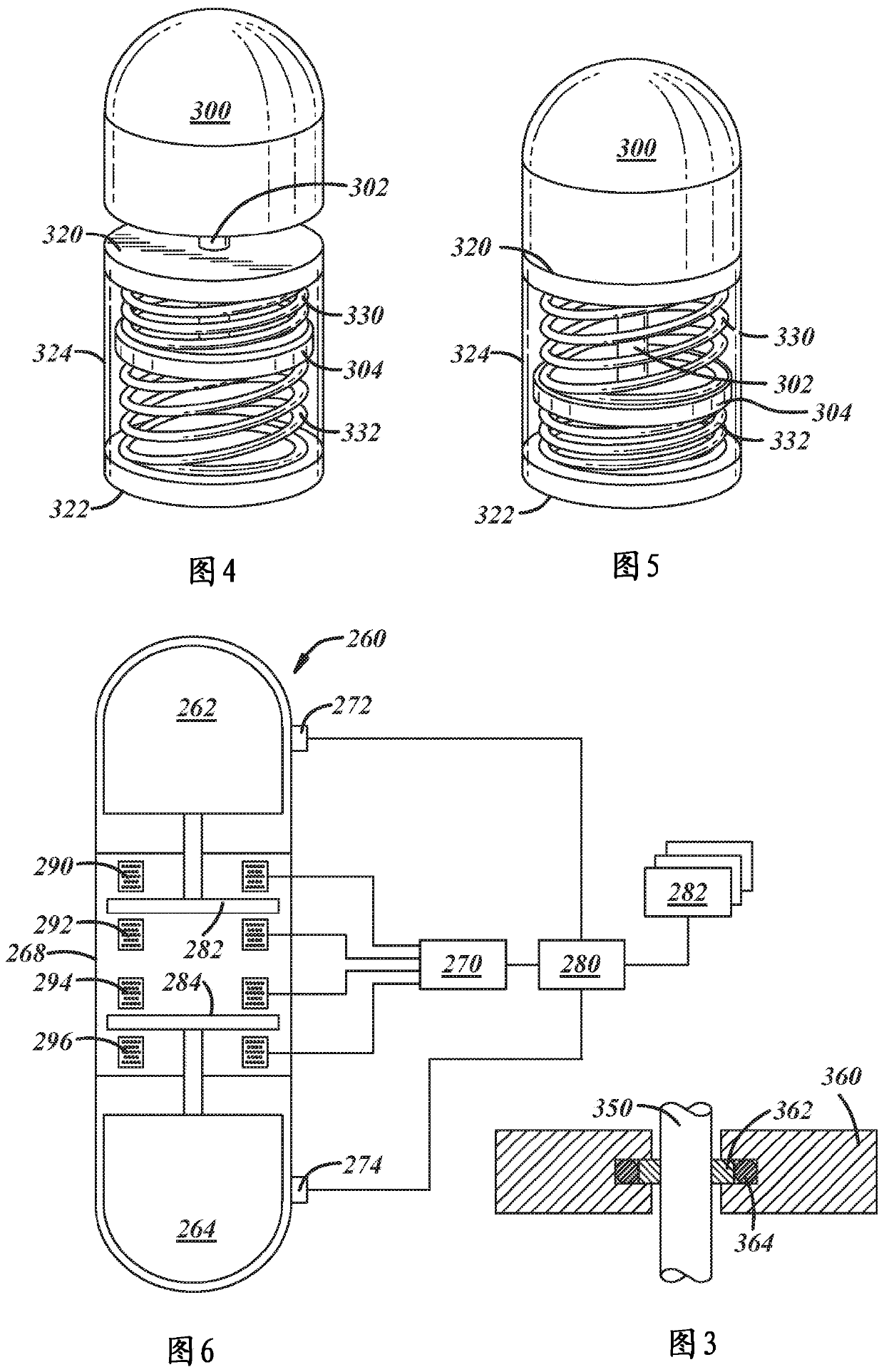

[0043] As will be understood by those of ordinary skill in the art, various features of the embodiments shown and described with reference to any one figure may be combined with features shown in one or more other figures to create alternatives not expressly shown or described Example. The combinations of features shown provide representative embodiments for typical applications. However, various combinations and modifications of the features consistent with the teachings of the present invention are contemplated for particular applications or implementations. Similar applications or implementations will be recognized by those of ordinary skill in the art, whether or not explicitly described or shown.

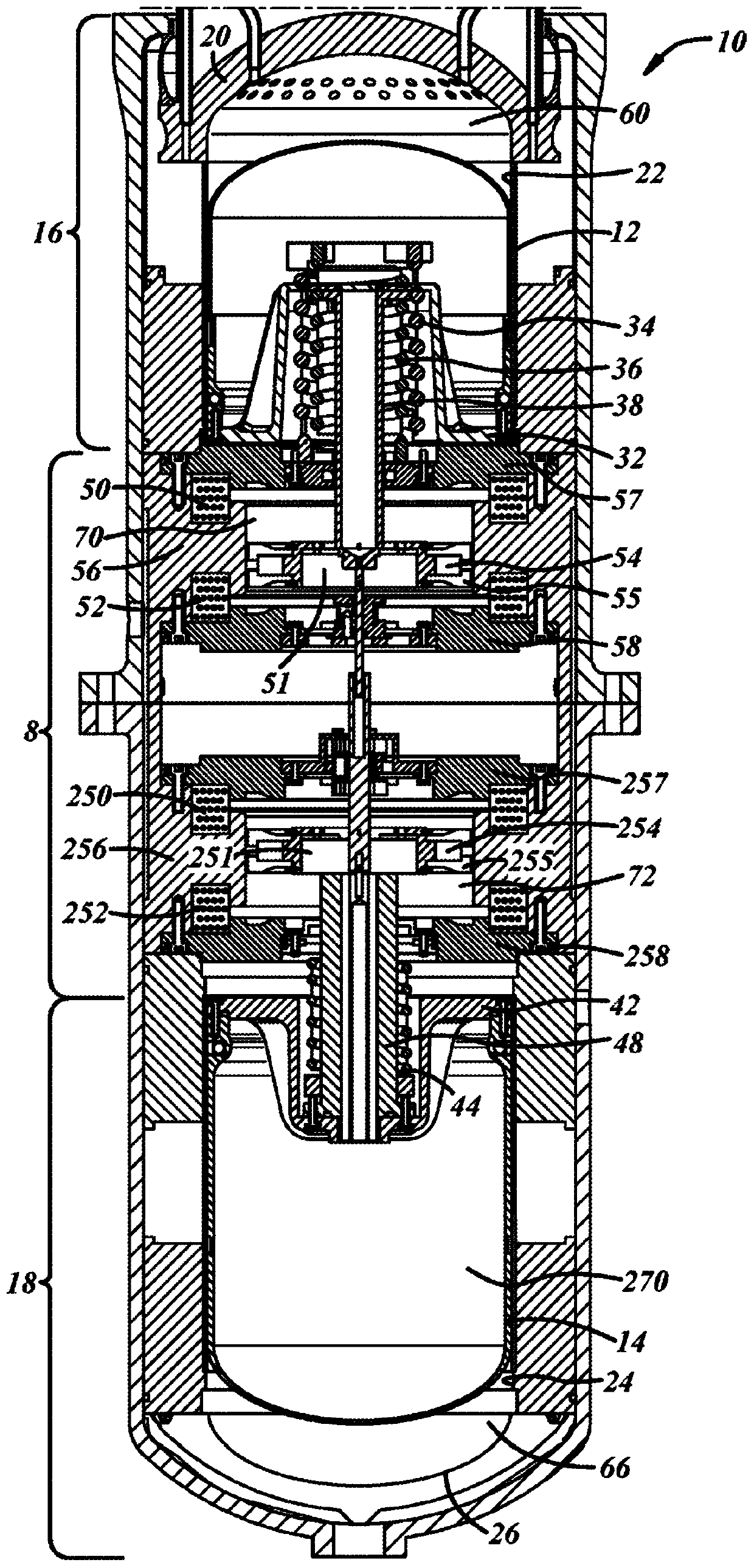

[0044] exist figure 2 In it, the heat pump 10 has a heat displacer portion 16 that includes the heat displacer 12 reciprocating within a heat displacer cylinder 22 . The heat pump 10 also has a cold displacer portion 18 that includes the cold displacer 14 reciprocating with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap