Photoelectric switch of threading machine

A photoelectric switch, threading machine technology, applied in electronic switches, thread trimmers, electrical components and other directions, can solve problems such as damage to the threading machine, and achieve the effect of low cost and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

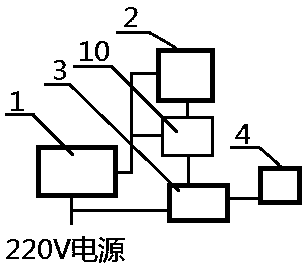

[0022] Example 1 see figure 1 A kind of photoelectric switch of thread threading machine, including strong and weak current transformer system 1, photoelectric switch 2, motor control device 3, motor 4, described motor 4 is connected with motor control device 3, accepts the control of motor control device 3, The motor control device 3 is connected to the photoelectric switch 2 to accept the control of the photoelectric switch 2, and the photoelectric switch 2 is connected to the strong and weak voltage transformation system 1 to receive the transformed safe voltage. In this embodiment, the photoelectric switch converts the change of light within the detection range into the change of electrical signal, and the process is a non-physical contact control process.

Embodiment 2

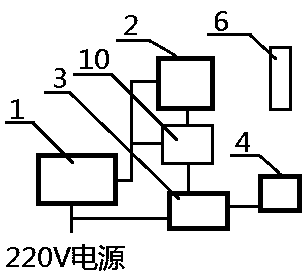

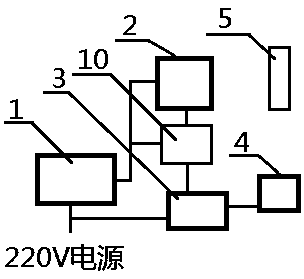

[0023] Example 2 see figure 2 , 3 With reference to Embodiment 1, in the application of Embodiment 1, when the photoelectric switch 2 detects the cutterhead 5, the photoelectric switch 2 controls the motor to shut down.

[0024] Further, when the photoelectric switch 2 detects the pipe wrench 6, the photoelectric switch 2 controls the motor to be in a shutdown state, so that the motor cannot be started.

[0025] Very good, the pipe wrench 6 detected by the photoelectric switch 2 is an abnormal operation process, which is explicitly prohibited by the manufacturer in the neighborhood to which it belongs. The existing technology does not prohibit it technically, and it is completely controlled by the user. The invention is technically set up, prohibiting abnormal operation procedures.

Embodiment 3

[0026] Embodiment 3 see Figure 4 , in combination with embodiments 1 and 2, a threading machine using a photoelectric switch, including a photoelectric switch of a threading machine and a threading machine itself, is characterized in that: the photoelectric switch of the threading machine The photoelectric switch is installed on the slide frame 11 of the threading machine 9, the motor control device on the photoelectric switch of the threading machine is connected with the local control device 10 of the threading machine, and the photoelectric switch 2 is used to detect the threading machine The position change of the cutterhead 5 on the machine when the cutter is retracted or the appearance of the pipe wrench 6.

[0027] Further, in the use of this embodiment, the pipe threading machine is threaded at the die head of the threading machine, the control device 10 of the threading machine is closed and the photoelectric switch starts the motor together, and the photoelectric sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com