A measuring device and measuring method for the hot state roll gap of the hydraulic segment of the continuous casting machine

A measurement method and measurement device technology, applied in the configuration of indicating equipment/measurement equipment, casting equipment, manufacturing tools, etc., can solve the impact of continuous casting machine equipment and slab quality, interference with continuous casting machine roll gap cold state management, On-line cold roll gap management accuracy is difficult and other problems, to achieve the effect of improving service life, stabilizing slab quality, and reasonable roll gap control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

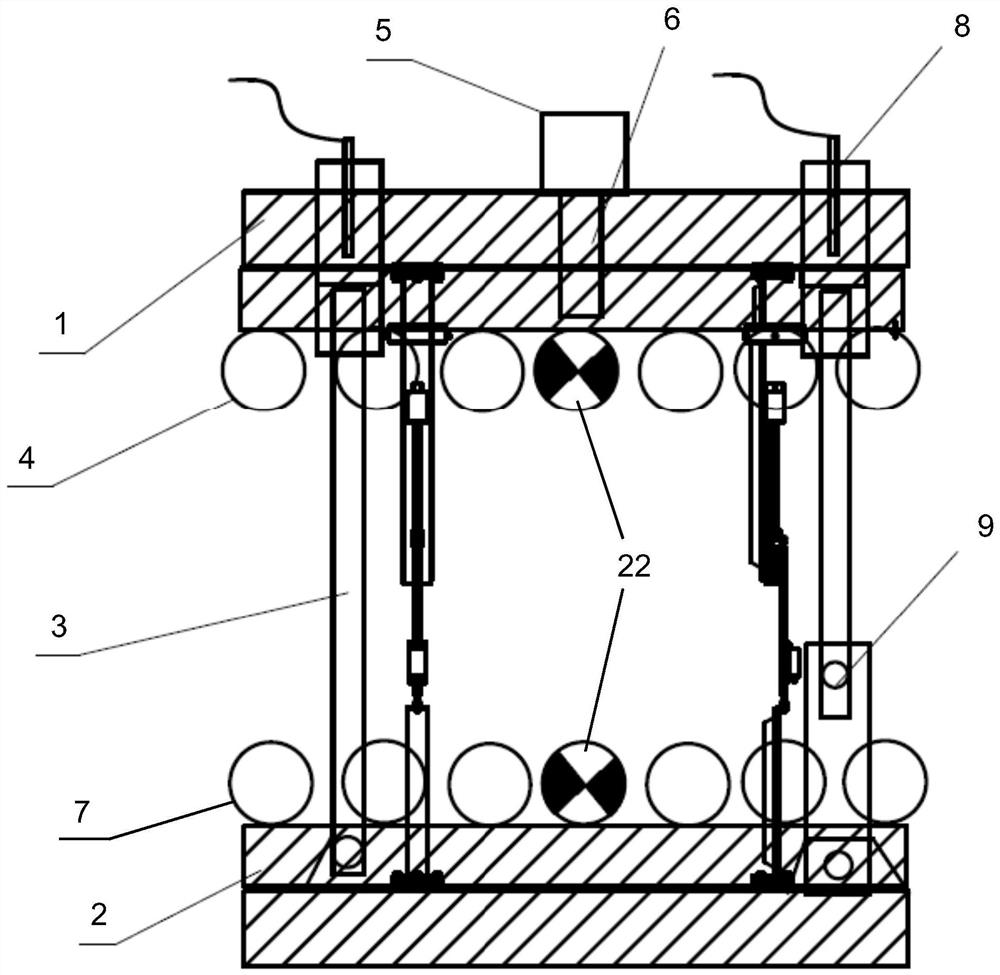

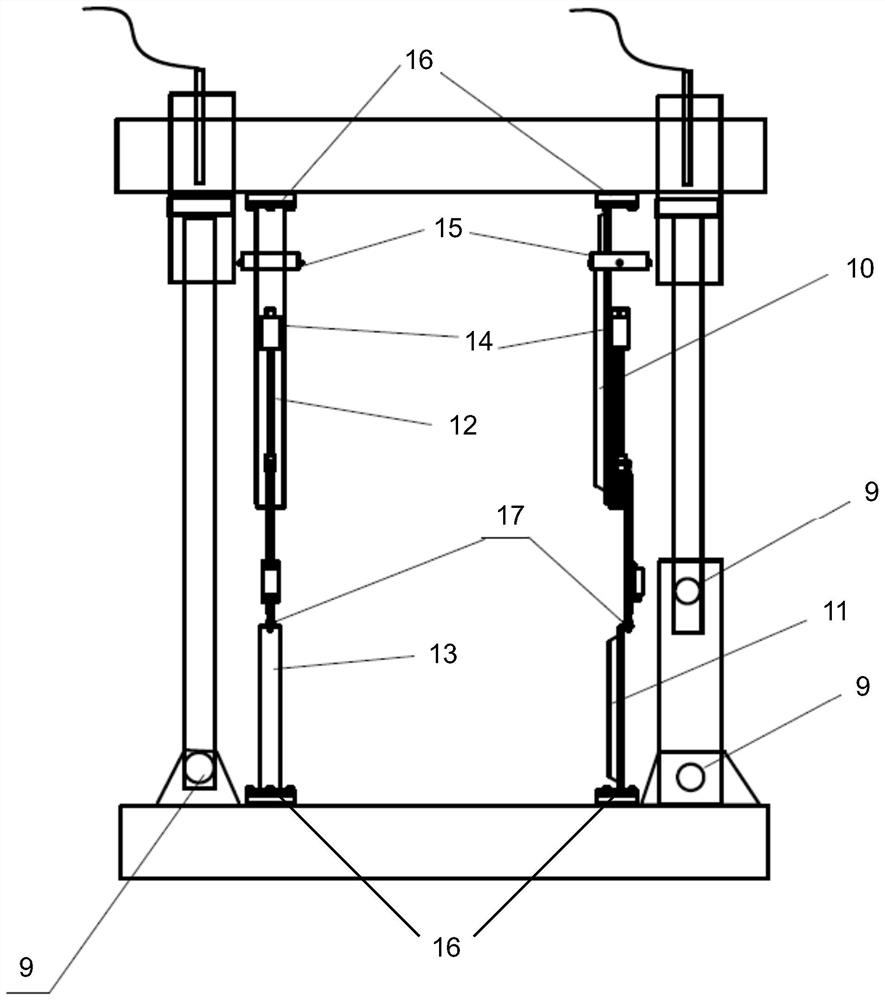

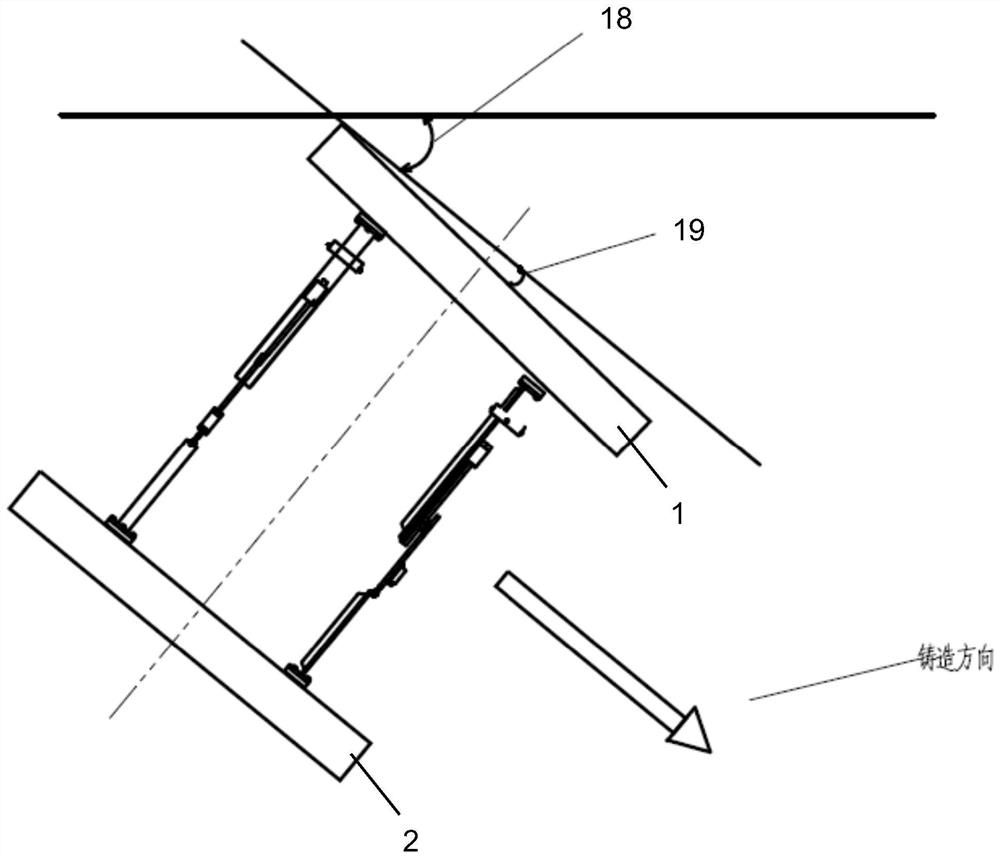

[0038] Please combine Figure 1 to Figure 2 As shown, the present invention provides a measuring device for the hot state roll gap of the hydraulic segment of the continuous casting machine. The hydraulic segment of the continuous casting machine includes: the upper frame 1 of the segment, the lower frame 2 of the segment, and the The four upper and lower frame connecting columns 3 between the frame 1 and the lower frame 2 of the fan-shaped section, the upper roller group 4, the lifting cylinder 5, and the lifting archway 6 arranged on the upper frame 1 of the fan-shaped section are arranged on the lower frame 2 of the fan-shaped section. The lower roller group 7, the upper end of the upper and lower frame connecting column 3 is provided with a roll gap control cylinder 8 with a displacement sensor, and there are multiple uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com