Assembly method based on 5G and industrial AR and using unrestrained force feedback

An assembly method and binding force technology, applied in the field of virtual assembly, can solve problems such as inability to move freely, and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

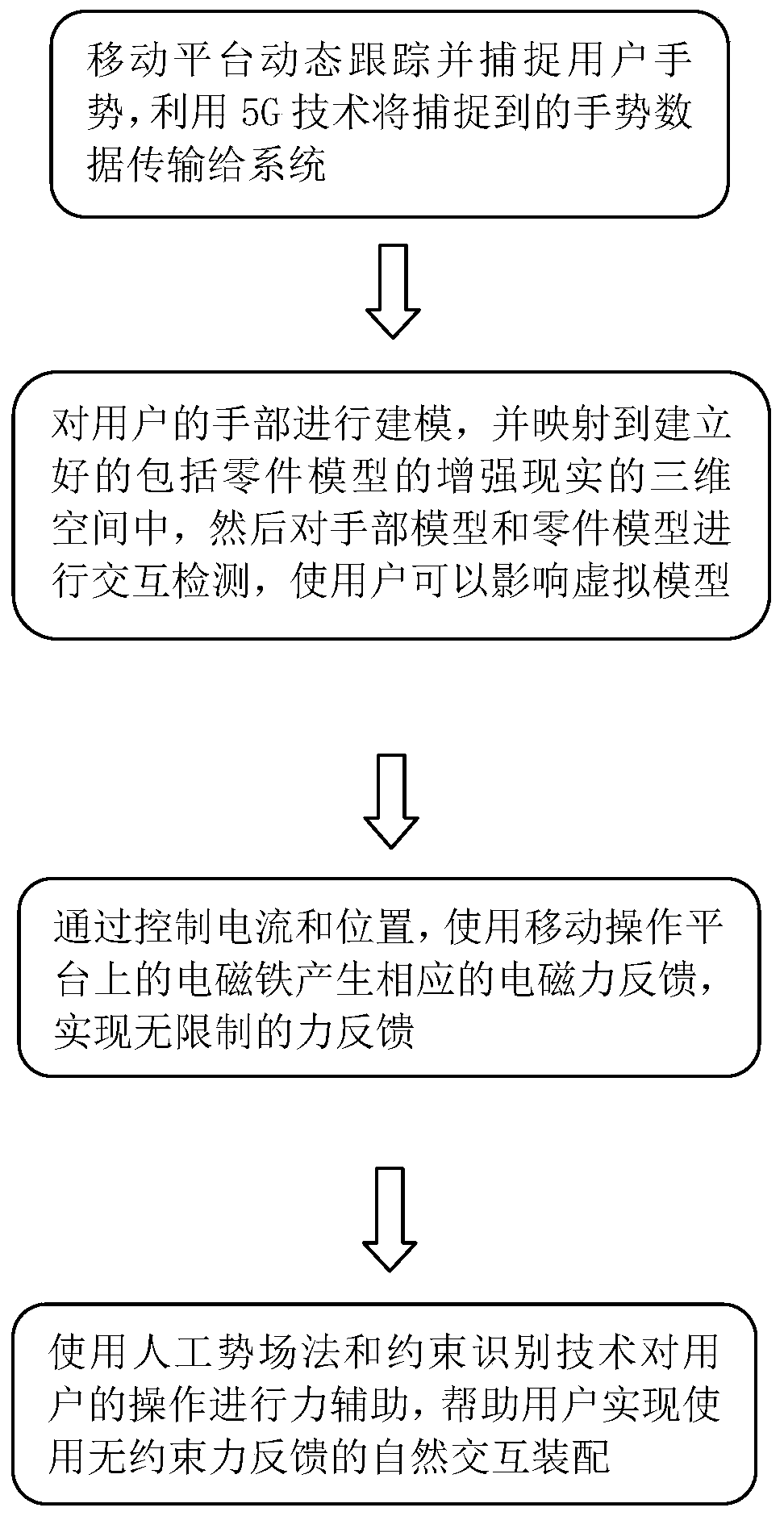

[0042] A 5G+industrial AR-based assembly method using non-binding feedback, comprising the following steps:

[0043] S1. Use the mobile operating platform to dynamically track and capture the user's gesture data, and use 5G technology to transmit the captured gesture data to the computer;

[0044] The mobile operating platform includes a mobile trolley and a mechanical arm, the mechanical arm is fixed on the mobile trolley, and a platform is arranged at the end of the mechanical arm, and an electromagnet and a camera for capturing gesture data are installed on the platform; A glove with a magnet array to feel the electromagnetic force; when the user operates, put the gloved hand above the electromagnet of the platform, and capture the gesture data through the camera fixed on the platform above the bracket. When moving, the computer will guess the direction of movement of the hand based on the returned gesture data, and then use the 5G network to transmit information to the rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com