Movable exhaust pipe material frame system

An exhaust pipe and material rack technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of heavy workload of assembly workers, save manpower and time, avoid manpower lifting, and avoid musculoskeletal damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific implementation manners of the present invention will be further elaborated below in conjunction with the accompanying drawings.

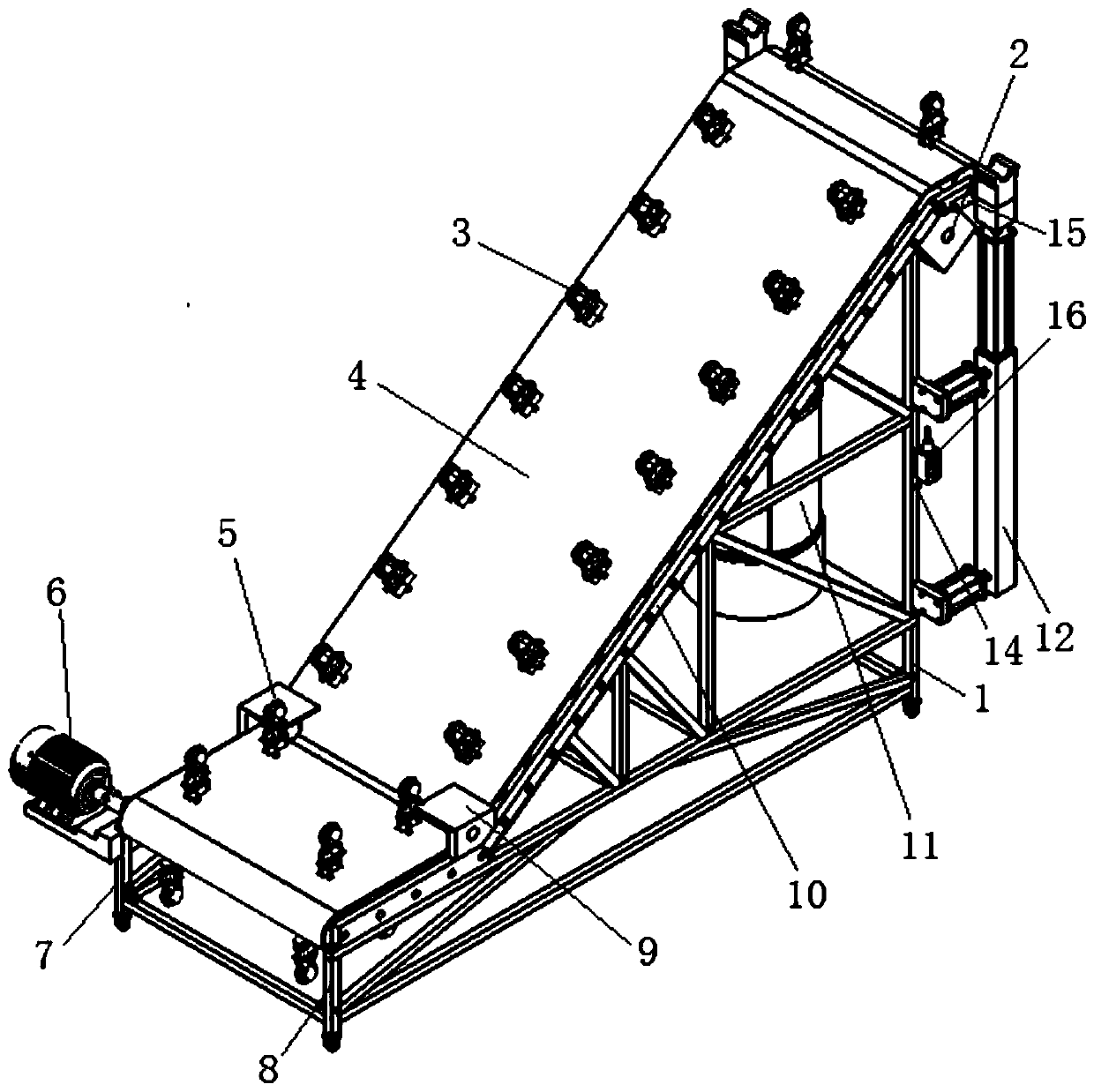

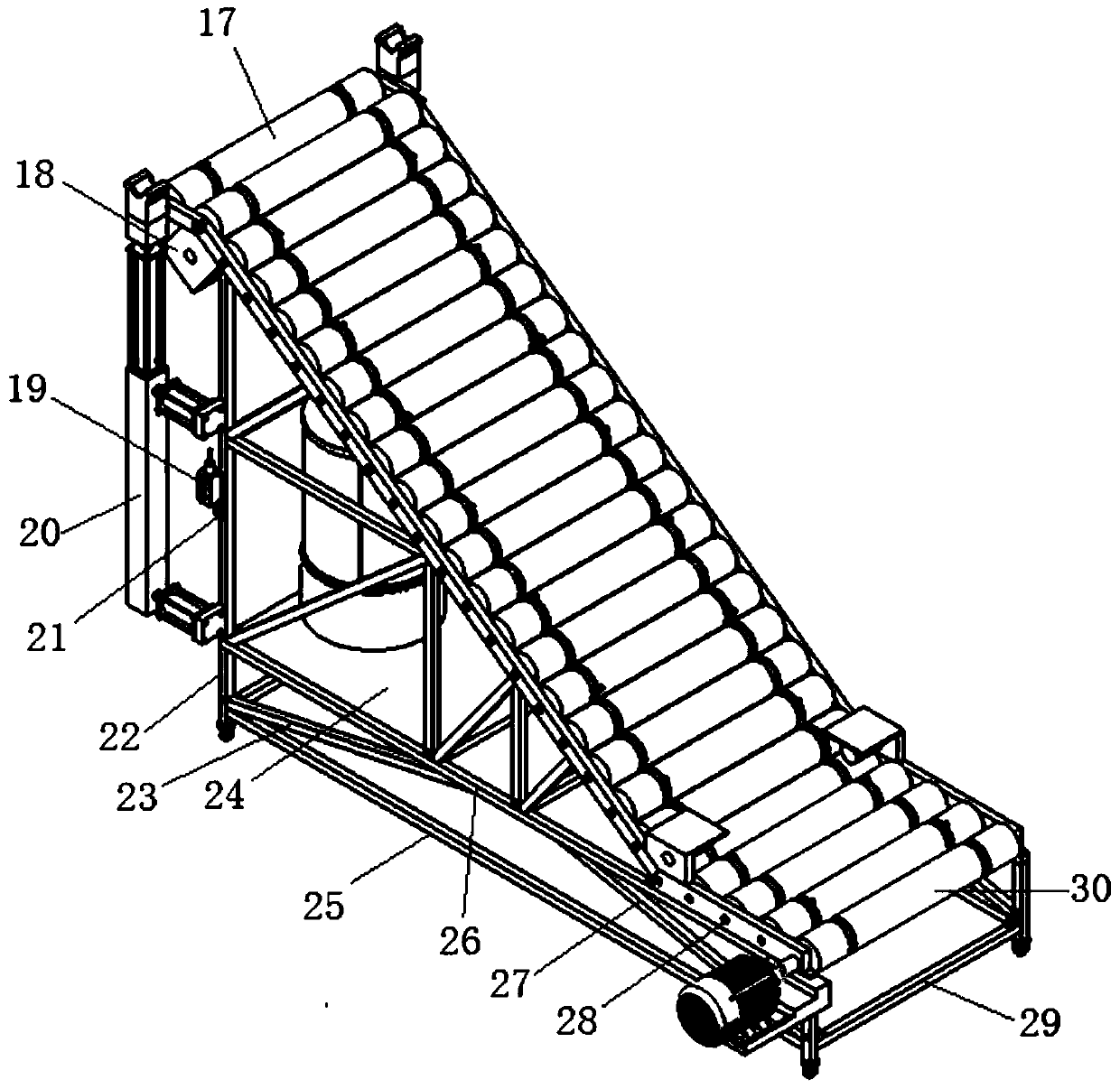

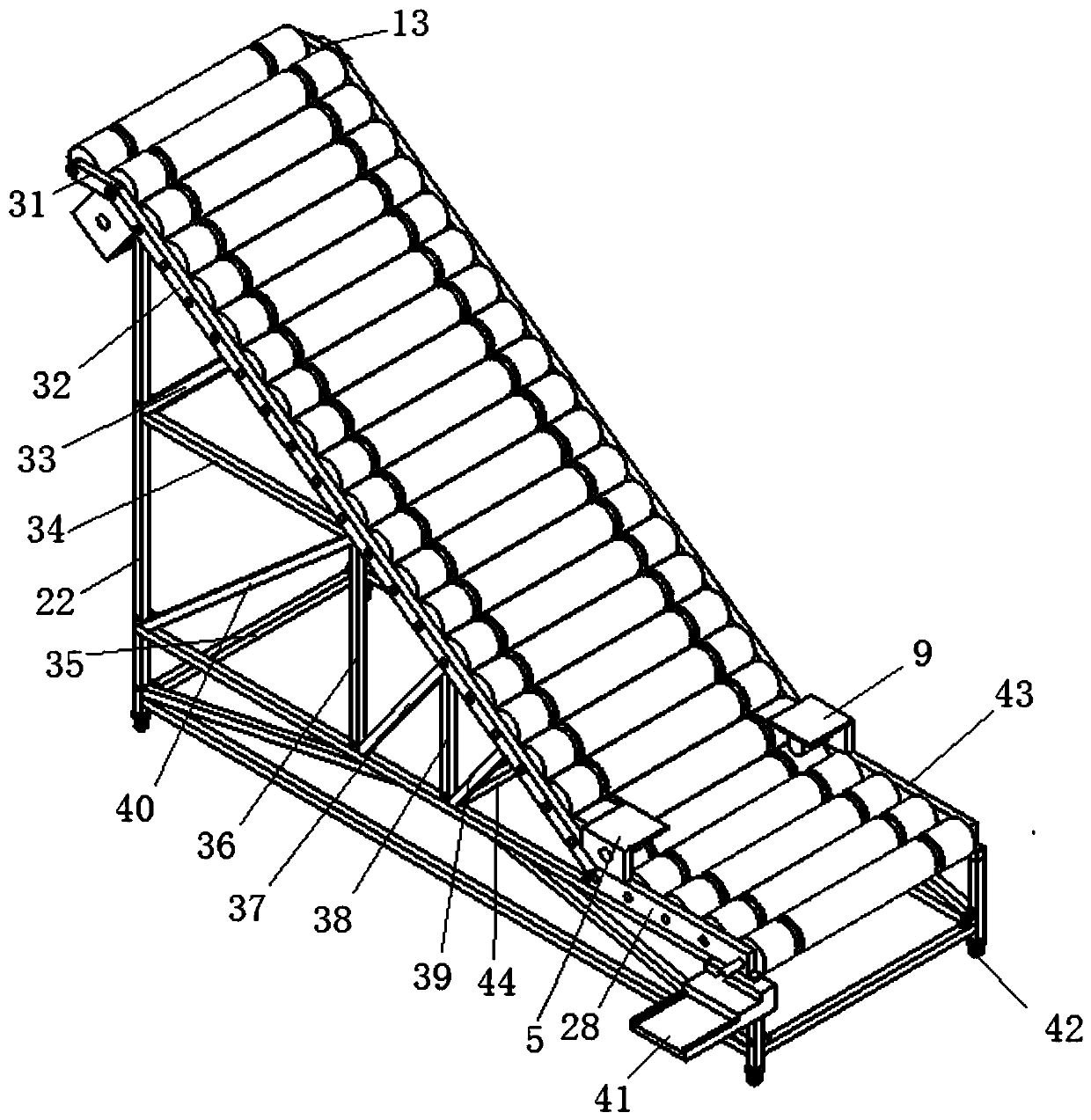

[0070] A mobile exhaust pipe material rack system, such as figure 1 As shown, it includes a conveyor belt 4 arranged in a Z shape as a whole, a central controller, a control switch I16, a control switch II 19 and two sets of pneumatic lifting devices (pneumatic lifting device I12 and pneumatic lifting device II 20), the conveyor belt 4 The middle section is an inclined slope with a slope of 30°, and the conveyor belt 4 is supported by a bracket;

[0071] stent such as figure 2 and 3 As shown, including the two side frames and the connectors connecting the two side frames (that is, a plurality of horizontal connecting beams connecting the two side frames, specifically the horizontal connecting beam I 29, the horizontal connecting beam II 35 and the horizontal connecting beam III 44), the two The side frames are identical and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com