A kind of continuous winding fiberglass reinforced pipe preparation method

A technology of coiled tube and reinforced tube, which is applied in the field of preparation technology of reinforced tube, can solve the problems of insufficient platform width, shorten the width of inner and outer filament winding layers, etc. The effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

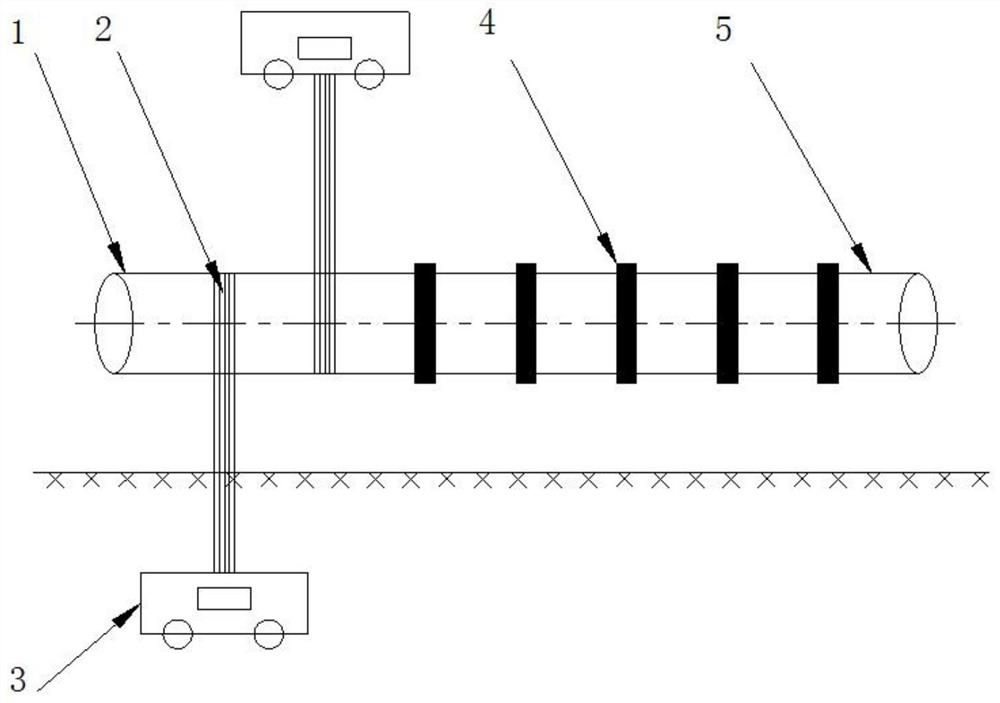

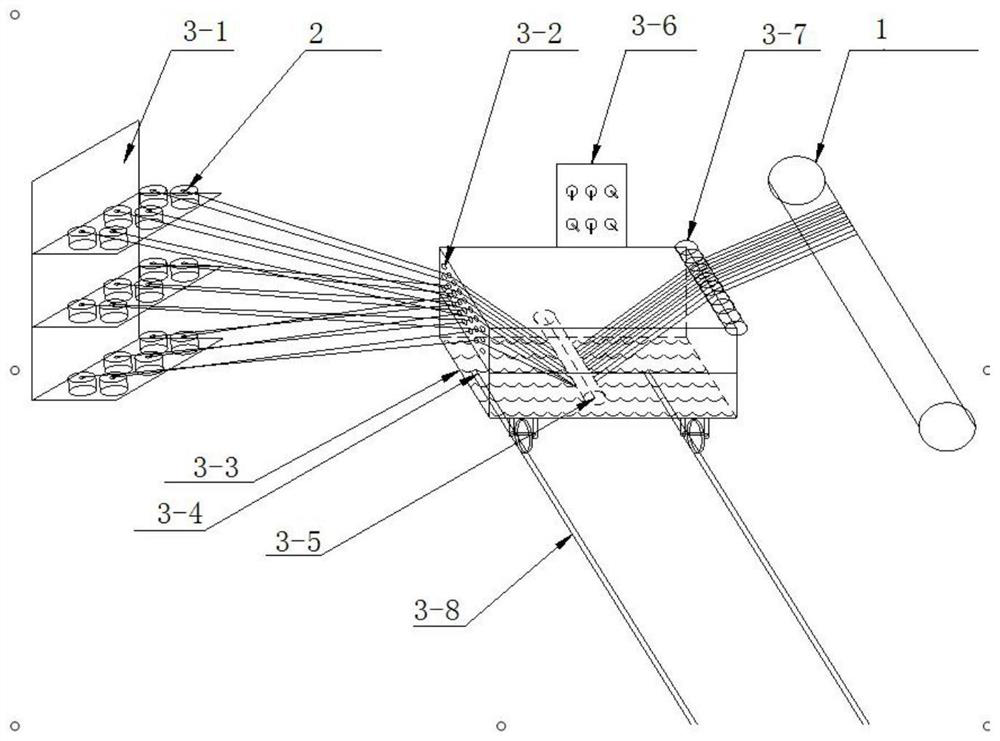

[0030] like figure 1 As shown, taking the DN2000-PN6-SN10000 reinforced pipe as an example, the technical solution of the present invention is described in detail:

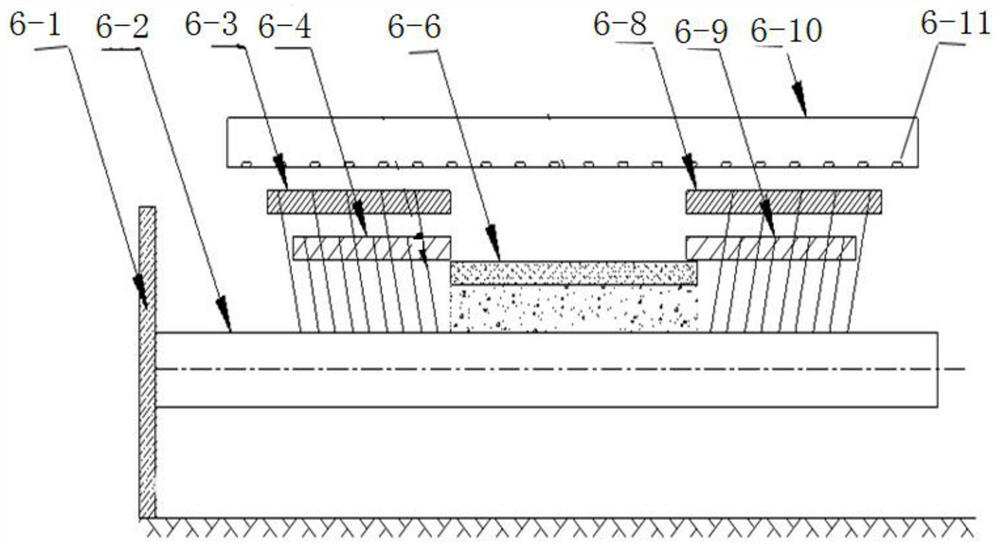

[0031] A. According to the design input DN2000, PN6, SN10000, without adding sand, the ultimate hoop tensile strength of the layer is 457MPa, and the ultimate axial tensile strength is 53MPa. According to the strength principle, it is calculated that the thickness of the pipe body is not low In order to ensure the anti-deformation ability of the pipeline when it is not reinforced, the rigidity of its body should not be less than 1250Pa, according to which the thickness of the pipeline body should not be less than 17.4mm. Whichever is larger, the thickness of the main body of the pipe is 17.4mm. Accordingly, the required number of structural winding strands is 234 strands of 2400TEX winding yarn, and a total of 23.4 layers need to be wound.

[0032] B. According to the number of layers of the coiled tube body in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com