Composite type melt-blown fabric web-forming method

A web-forming and melt-blown technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, can solve the problem of low tensile strength of melt-blown fabrics, and achieve the effect of increased tensile strength and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

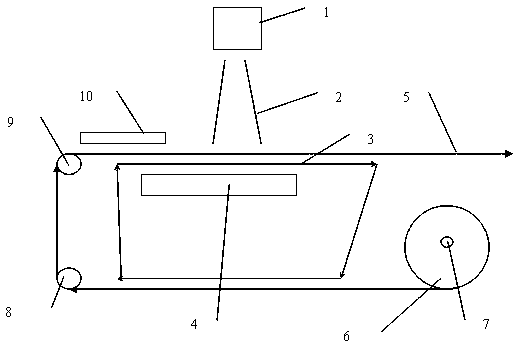

[0025] Embodiment 1: The technical solution of the present invention is made up of melt-blown mold, melt-blown yarn, web-forming machine cloth, suction fan, spunbonded non-woven fabric, unwinder, shaft, guide roller, flattening roller, and cooling fan;

[0026] Described web forming machine cloth is PTE net;

[0027] Described unwinding machine is used for installing spun-bonded non-woven fabric;

[0028] The guide roller changes the direction of the spunbonded nonwoven fabric;

[0029] Described flattening roller is used for flattening non-woven fabric, does not wrinkle;

[0030] The refrigerating fan is used to reduce the spunbond nonwoven fabric to 5 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com