Prefabricated sleeve arch for reinforcing and maintaining tunnel lining

A technology for lining and tunneling, applied in the field of prefabricated sleeve arches, can solve the problems of difficult to guarantee the quality of cast-in-place construction, serious overlapping of construction procedures, and increased pressure of local traffic, etc., and achieves the effects of good waterproof effect, simple assembly, and less traffic time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Prefabricated Arches for Tunnel Lining Reinforcement and Maintenance

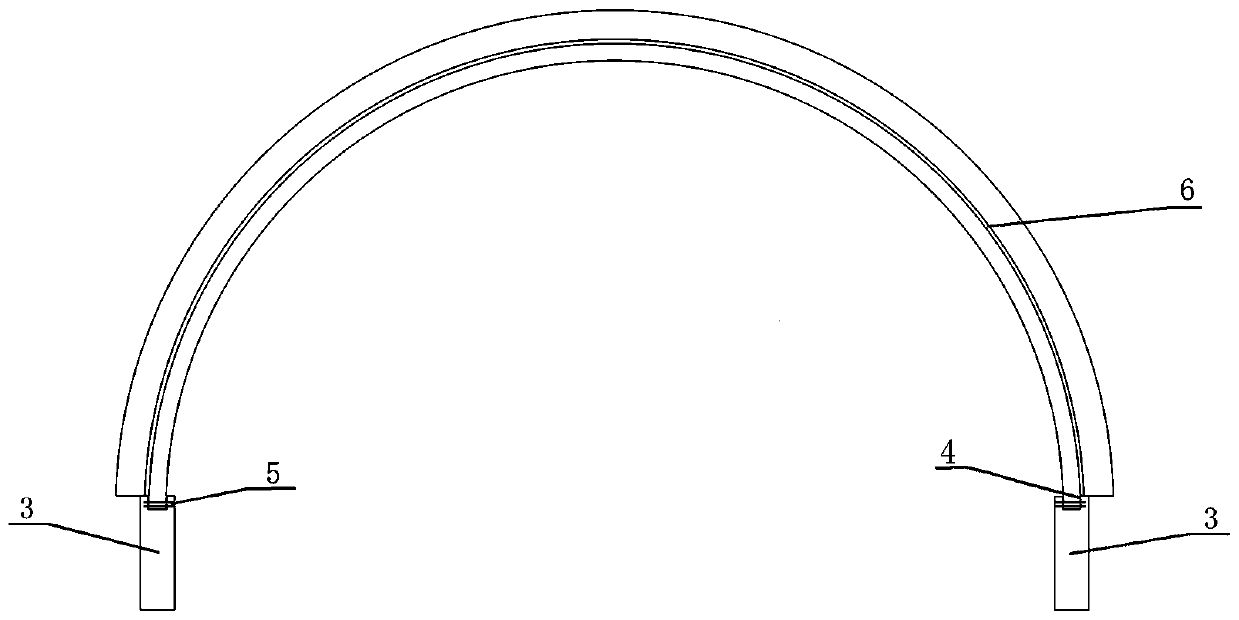

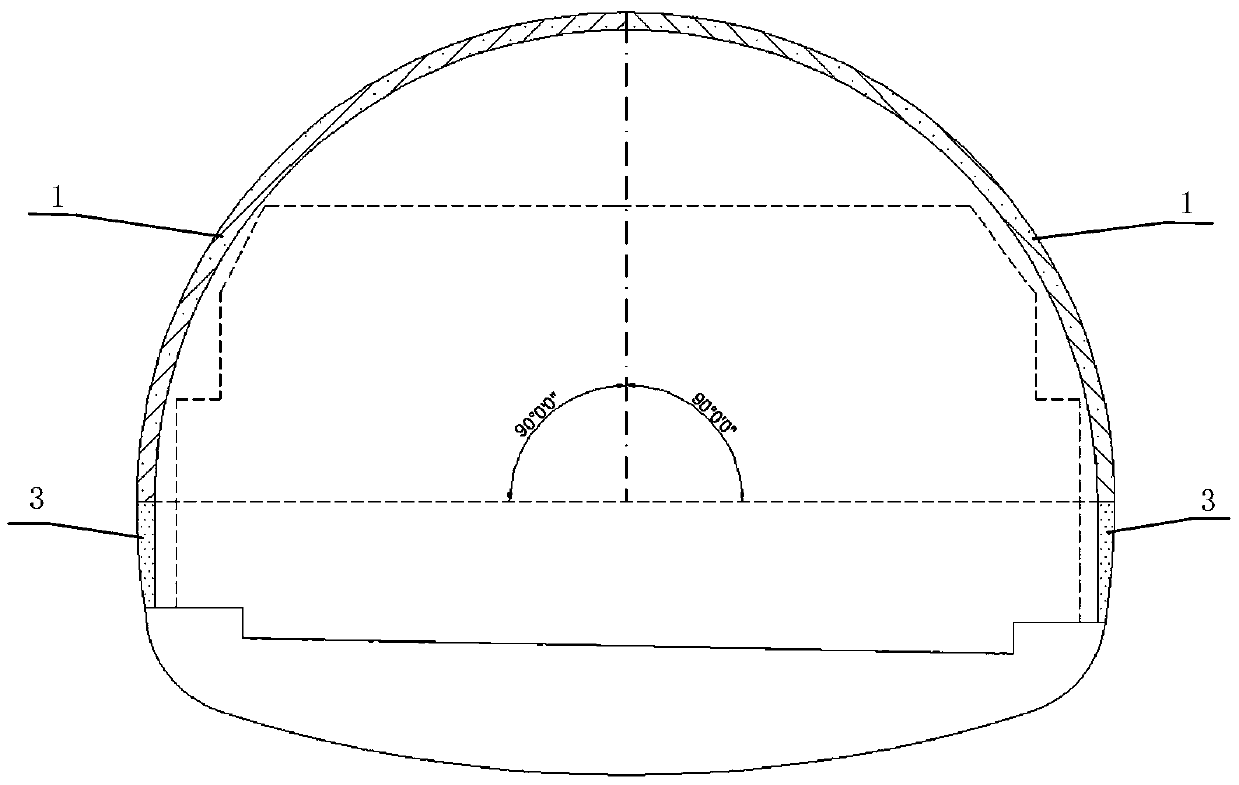

[0031] This example figure 1 and figure 2 As shown, it includes two first prefabricated lining blocks 1, two concrete pedestals 3 and waterproof cloth 6, the first prefabricated lining block 1 is an arc-shaped sheet structure, and the corresponding central angle of the first prefabricated lining block 1 is 90 degrees Therefore, two first prefabricated lining blocks 1 can be spliced and installed in the circumferential direction to form an arched structure with a semicircular cross section.

[0032] The circumferential end of the concrete pedestal 3 and the first prefabricated lining block 1 is fixedly connected by a socket joint. To the through hole and the bolt 5 on the preset concrete pedestal 3, when installing, insert the circumferential end of the first prefabricated lining block 1 into the groove 4, at this time, the diameter of the bolt 5 and the first prefabricated lining block...

Embodiment 2

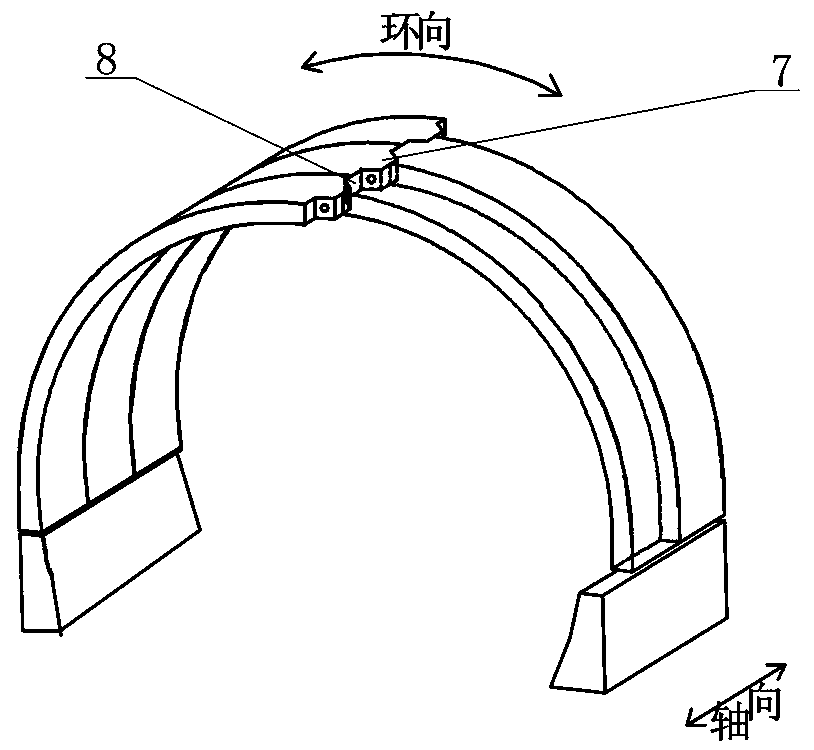

[0038] This example figure 1 and Figure 4 As shown, it includes three second prefabricated lining blocks 2, two concrete pedestals 3 and tarpaulin 6, such as Figure 5 As shown, the second prefabricated lining block 2 is an arc-shaped sheet structure, and the corresponding central angle of the second prefabricated lining block 2 is 60 degrees. Therefore, three second prefabricated lining blocks 2 can be spliced and installed in the ring direction so that the section is half Round arched structure.

[0039] The circumferential ends of the concrete pedestal 3 and the second prefabricated lining block 2 arranged at both ends of the arch structure are fixedly connected by a socket joint, and the socket joint includes a groove 4 arranged on the top of the concrete pedestal 3, and a groove 4 arranged on the second The radial through hole on the prefabricated lining block 2 and the bolt 5 preset on the concrete pedestal 3, when installing, insert the circumferential end of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com