Coaxial central motor

A mid-motor, coaxial technology, applied in wheel drive devices, electromechanical devices, electrical components, etc., can solve problems such as affecting the service life of the motor, complex transmission process, and misalignment of axes, saving design space, The effect of simple transmission process and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

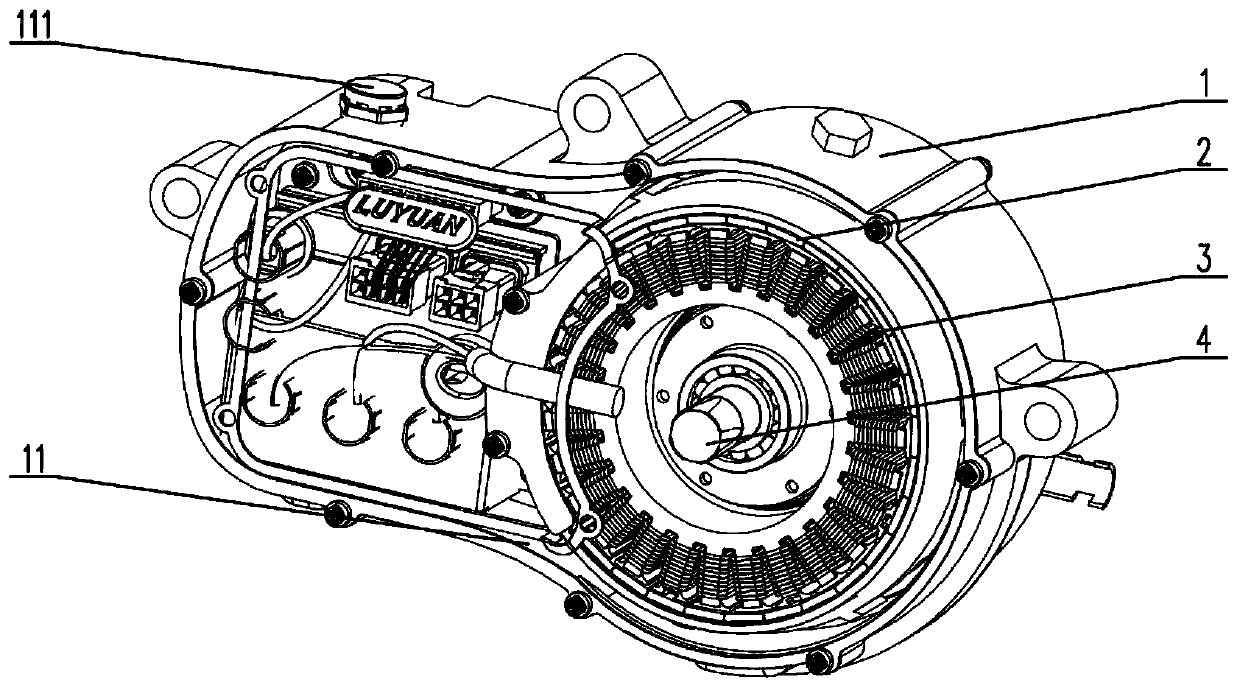

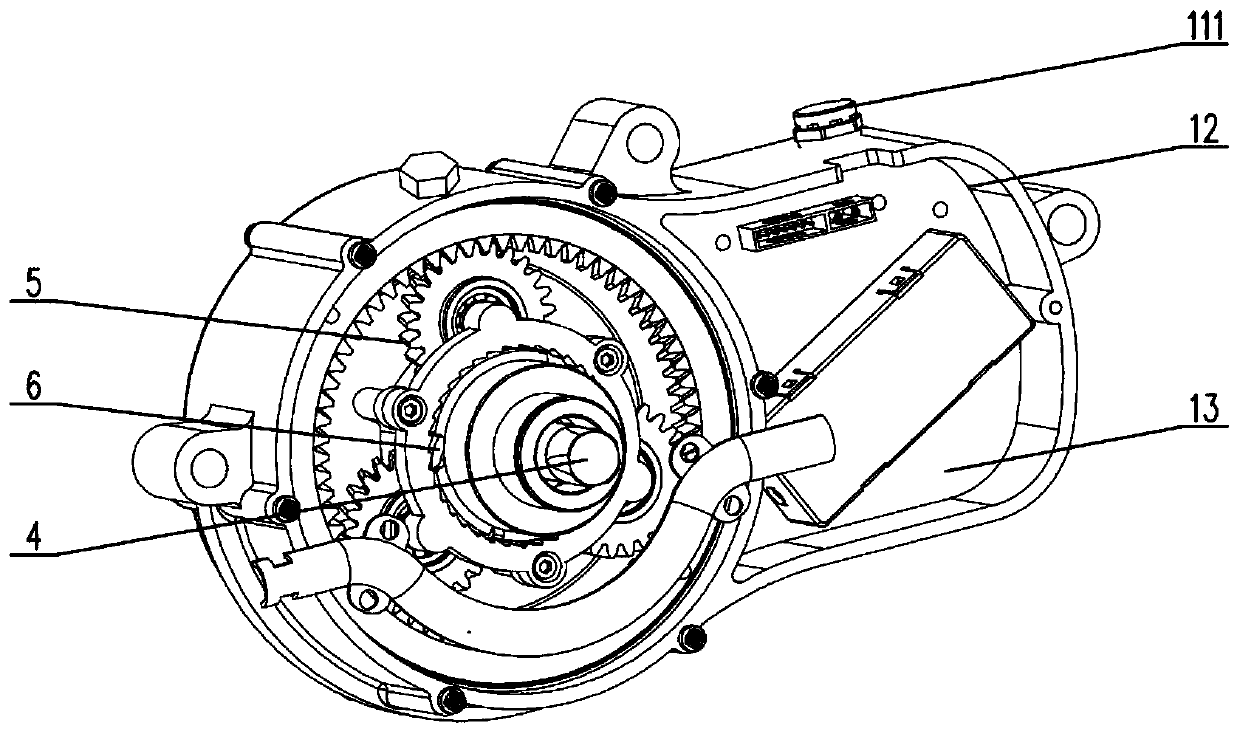

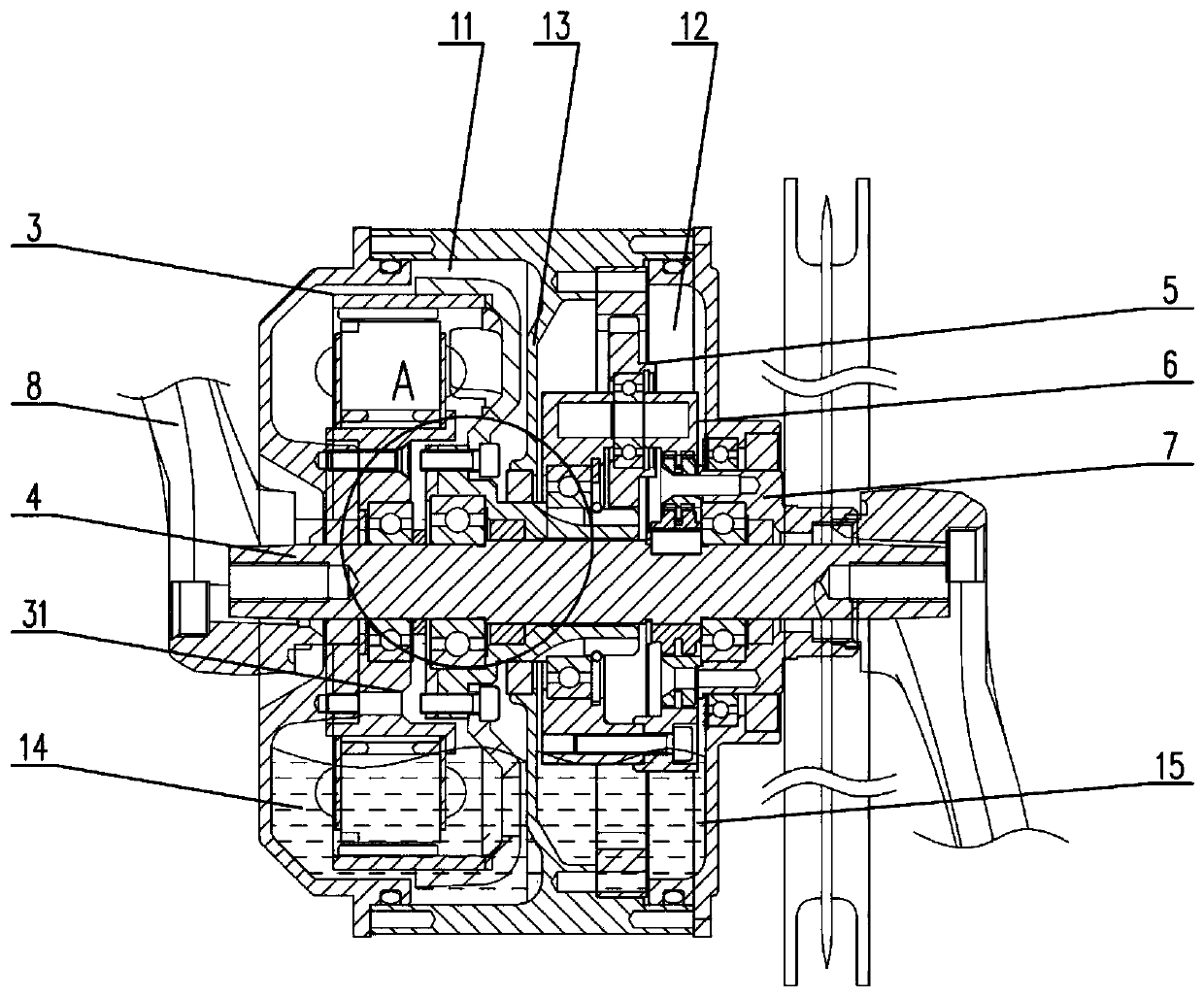

[0065] A coaxial mid-mounted motor, including a casing 1, a central shaft 4, a stator assembly 3, a rotor assembly 2, a transmission module 5, and a clutch module 6, the stator assembly 3, the rotor assembly 2, the transmission module 5. The clutch module 6 is located inside the casing 1, the stator assembly 3 is sleeved inside the rotor assembly 2 and connected to the casing 1, and the central shaft 4 passes through the stator assembly 3. The rotor assembly 2, the transmission module 5, and the clutch module 6, the transmission module 5 is connected to the rotor assembly 2, and the clutch module 6 is connected to the center shaft 4 and the transmission module 6 respectively. The modules 5 are connected, and the central shaft 4 passes through the casing 1 and extends out of the casing 1 .

[0066] When the motor is energized to work, the stator assembly 3 is energized, the rotor assembly 2 and the stator assembly 3 directly generate a Lorentz force, and the rotor assembly 2 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com