Crude oil storage tank automatic drainage oil retention system and drainage oil retention method thereof

A crude oil storage tank, automatic drainage technology, used in packaging, large containers, transportation and packaging, etc., to achieve the effect of adjustable displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

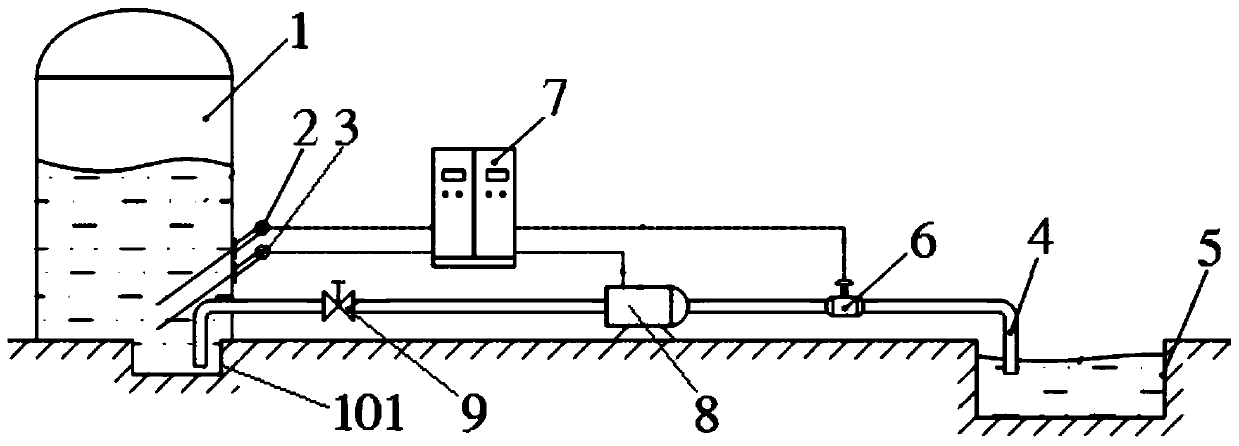

[0026] refer to figure 1 , the embodiment of the present invention proposes a kind of crude oil storage tank automatic drainage and cut-off system, comprising: crude oil storage tank 1, drainage pipeline 4 and CQ type oil-water on-line control device 7; The detector 2 is provided with a lower oil-water layer detector 3 at the bottom; the inlet of the drainage pipeline 4 leads to the bottom of the crude oil storage tank 1, the outlet of the drainage pipeline 4 leads to the sewage pool 5, and the drainage pipeline 4 is provided with a solenoid valve 6; The CQ type oil-water online monitoring device 7 is provided with a GJ type high-precision analog-to-digital converter, a CC type memory, an FX type analysis processor, a KZ type control circuit and a TX type communication circuit, and the CQ type oil / water online monitoring device 7 communicates with the RTU type remote control terminal signal connection, the signal input end of CQ type oil-water online monitoring device 7 is ele...

Embodiment 2

[0031] refer to figure 1 , on the basis of Embodiment 1, it also includes a drainage pump 8, and the drainage pump 8 is electrically connected to the signal output end of the CQ type oil-water online monitoring device 7.

[0032] The drainage pump 8 can pump the water in the crude oil storage tank 1 into the sewage tank 5 through the drainage pipeline 4, so as to increase the drainage speed.

Embodiment 3

[0034] refer to figure 1 , On the basis of Embodiment 1, the CQ type oil-water online monitoring device 7 is also provided with manual control buttons, which can control the solenoid valve 6 and the drain pump 8 respectively.

[0035] When the signal connection between the CQ-type oil-water online monitoring device 7 and the RTU-type remote control terminal is interrupted, the on-site staff can directly control the opening and closing of the solenoid valve 6 and the drainage pump 8 through the manual control buttons on the CQ-type oil-water online monitoring device 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com