Large-volume light asphalt tank type container

A kind of asphalt tank, large-volume technology, applied to large containers, tankers, containers, etc., can solve the problems of inconvenient transportation, low efficiency, long transportation time, etc., to achieve the effect of convenient transportation, prolonging the time, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

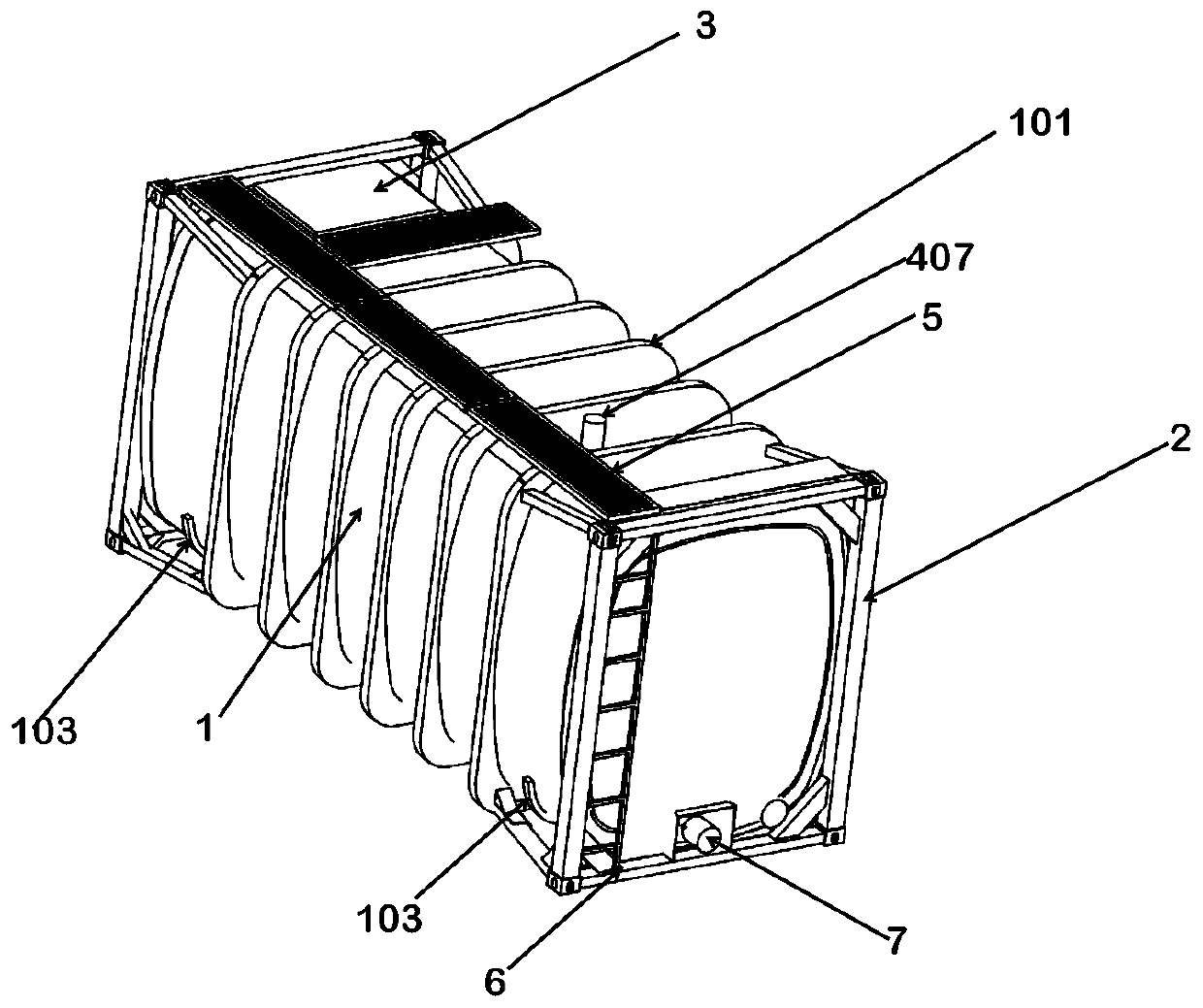

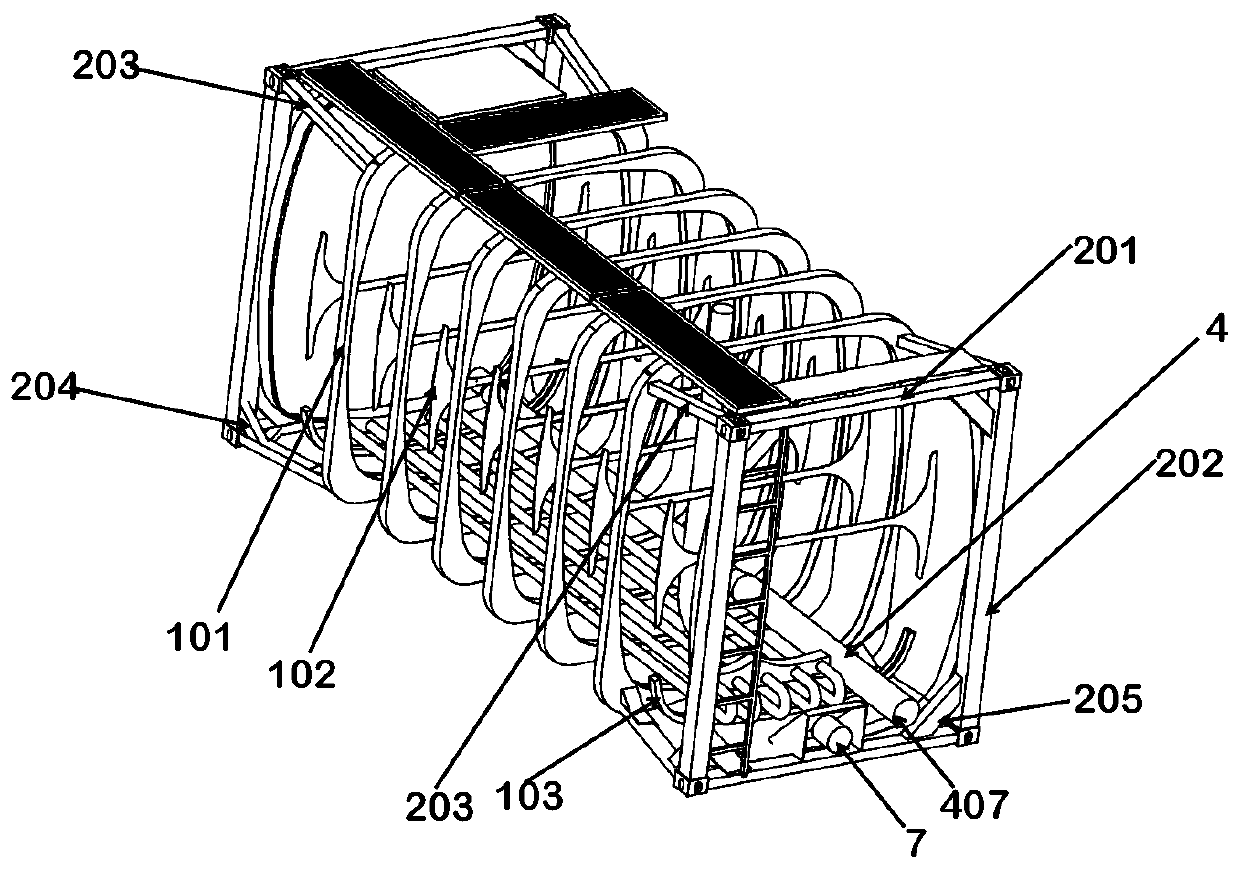

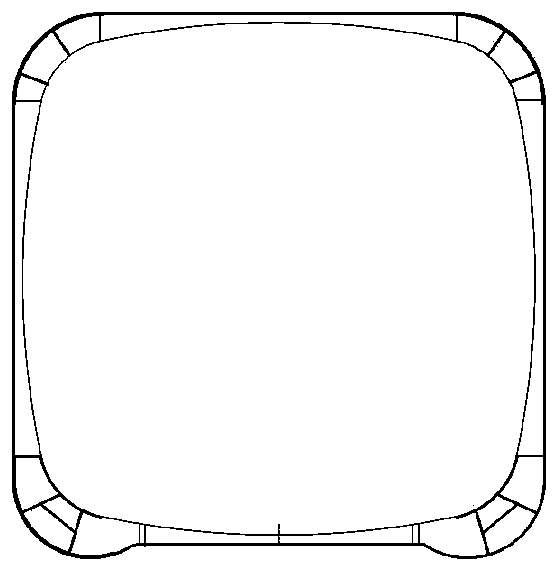

[0039] see Figure 1 to Figure 13 , a large-volume light-duty asphalt tank container, including a tank body 1 with a material inlet 3 on the top and a discharge port 7 on the side wall, and a plurality of external reinforcing ribs 101 are arranged on the periphery of the tank body 1. Internal reinforcement ribs 102 are erected between the inner walls of the tank body 1 adjacent to the outer reinforcement ribs 101, and multiple bottom reinforcement ribs 103 are provided at the bottom of the tank body 1;

[0040] Both ends of the tank body 1 are provided with a frame 2, the frame 2 includes a frame body composed of beams 201 and columns 202, and the four corners of the frame body are respectively connected to the outermost external reinforcing ribs 101 through diagonal supports 203;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com