Road and bridge construction concrete pile tube

A concrete pipe pile and concrete technology, applied in construction, sheet pile wall, heat treatment equipment and other directions, can solve the problems of increasing the cost and difficulty of pile foundation engineering, and achieve the effect of ensuring product bearing capacity and restraining concrete expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

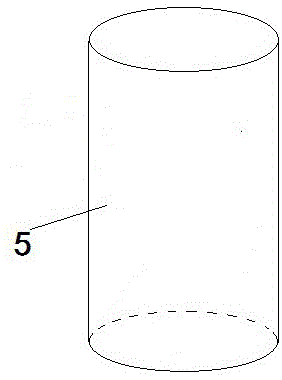

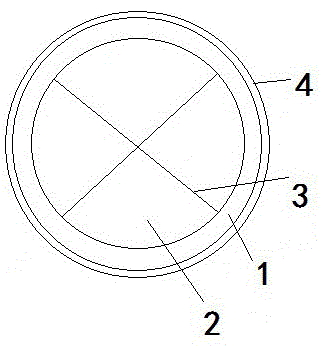

[0023] A concrete pipe pile for road and bridge, comprising a circular steel pipe and an organic coating layer coated with an organic paint on the outer wall of the circular steel pipe, the inner wall of the steel pipe is welded with a cross-reinforced beam, and the inside of the steel pipe is filled with concrete,

[0024] The chemical element composition of the round steel pipe is (weight percent): C: 0.22%, Mg: 4.1%, Mo: 2.3%,: Cr 2.1%, Mn: 0.72%, Sn: 0.63%, Bi: 0.54%, Nb: 0.34 ﹪, Ag: 0.13%, Ti: 0.073%, V: 0.052%, Sb: 0.031%, Zn: 0.022%, Pd: 0.024%, and the balance is Fe and unavoidable impurities;

[0025] The preparation method of the round steel pipe includes the following steps: according to the composition and ingredients of the above round steel pipe elements, the pure iron is first added to the smelting furnace, and the furnace temperature is controlled at 1450 ° C. After the pure iron is melted, the furnace temperature drops to 1440 ° C and added Magnesium-iron mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com