Special lifting appliance for automobile floor assembly

A spreader and floor technology, which is applied in the field of spreaders, can solve the problems that simple spreaders cannot meet high-intensity, large-scale production, labor intensity of workers, and low production efficiency, etc., and achieve simple clamping, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

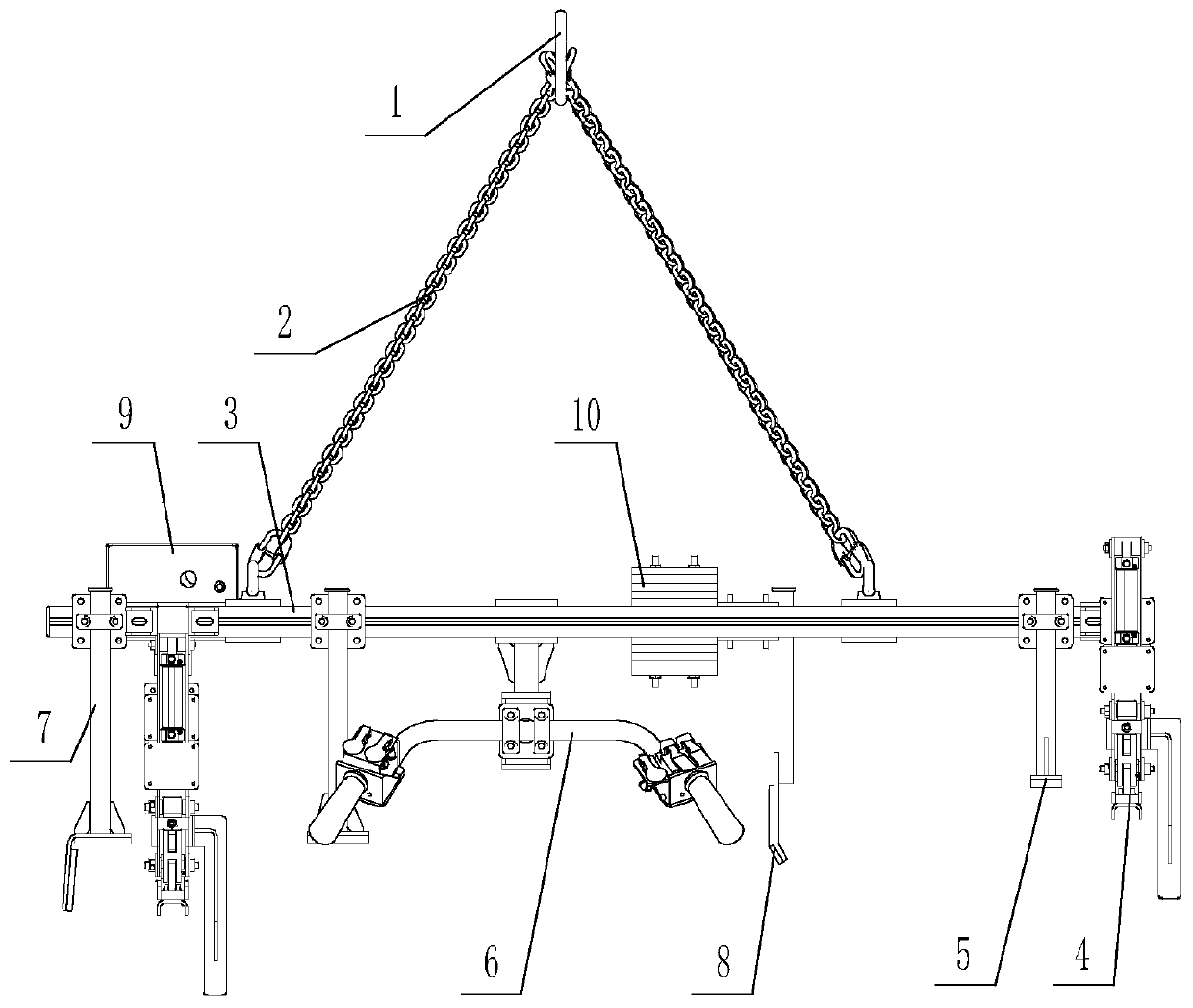

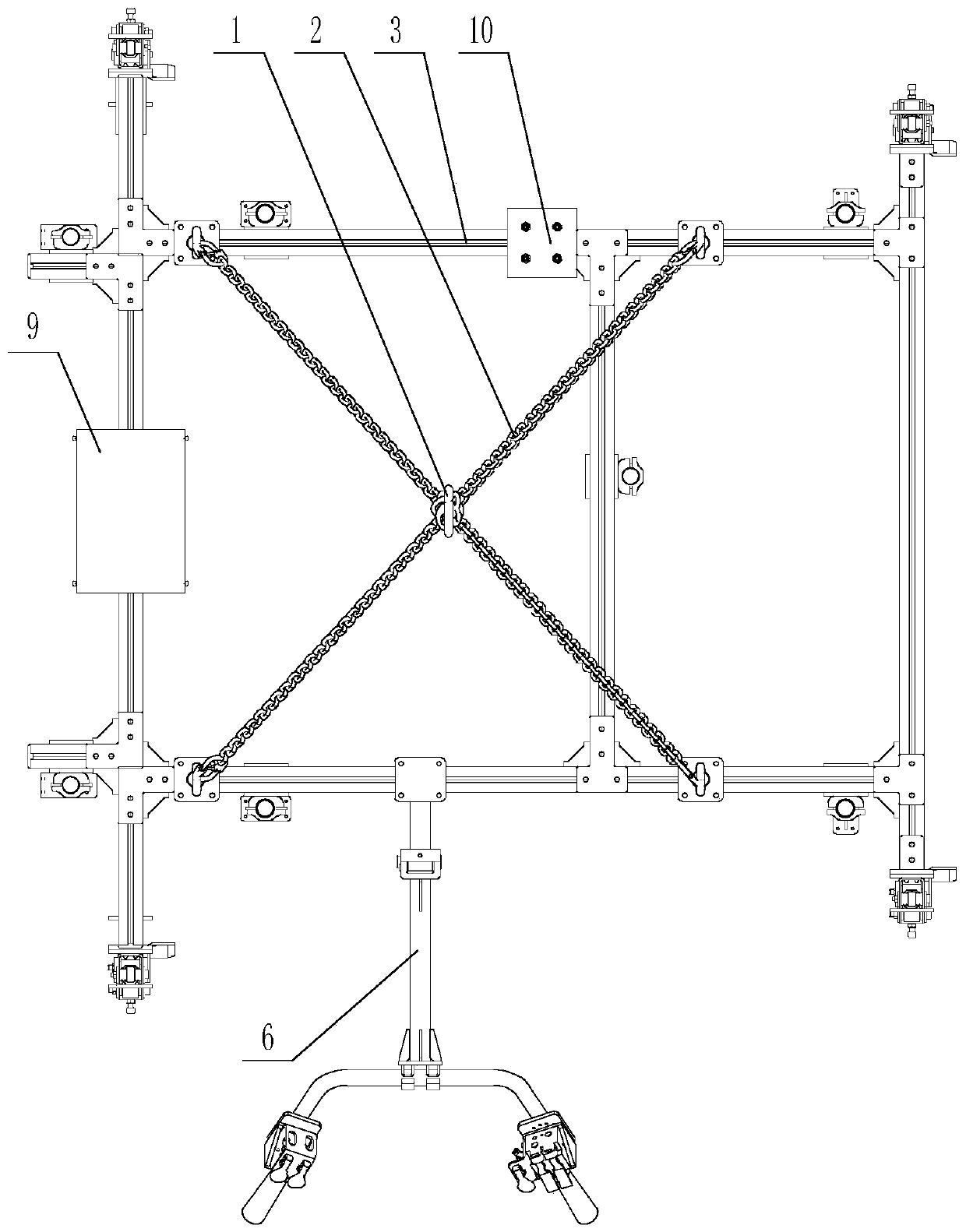

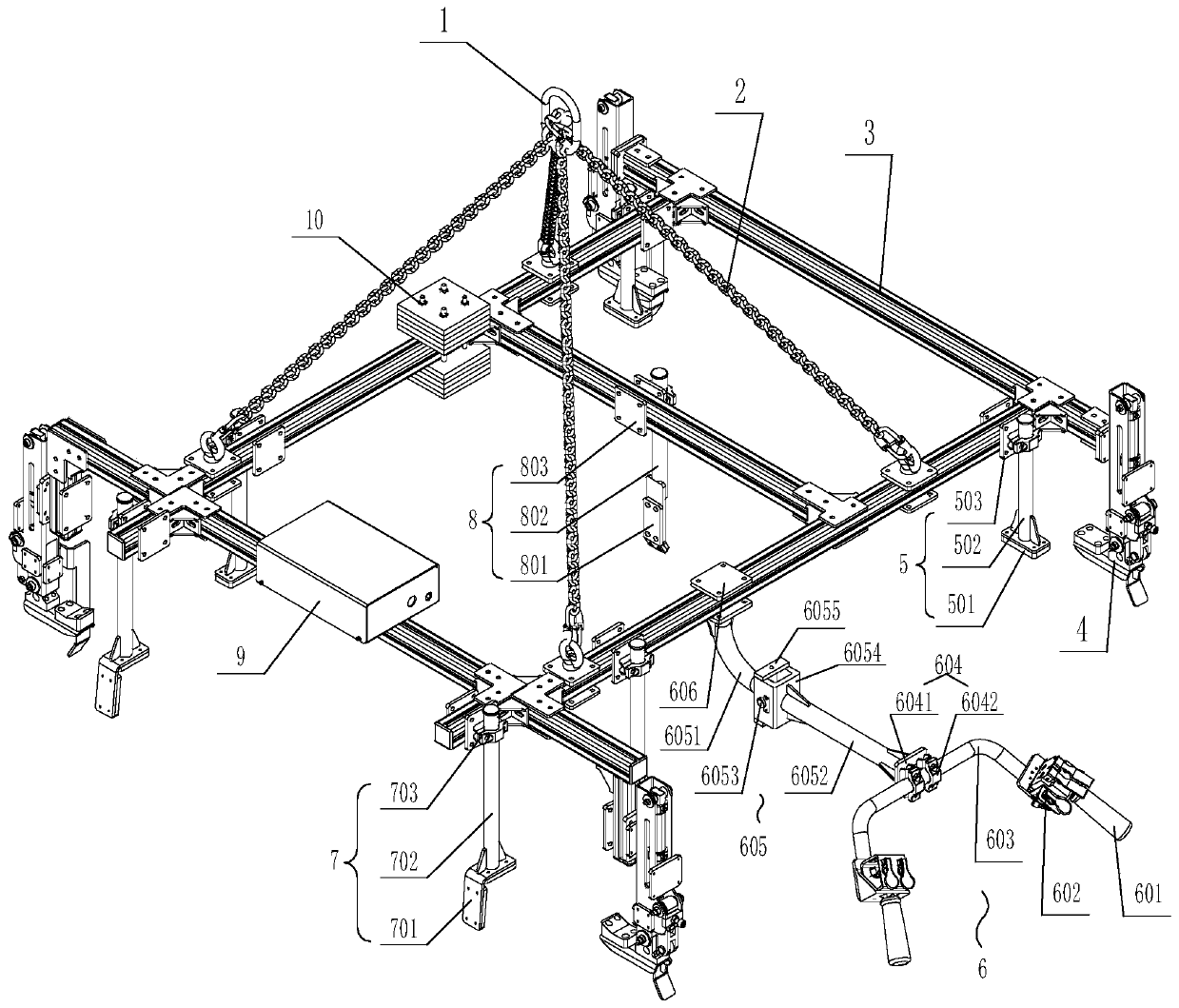

[0054] A special spreader for an automobile floor assembly, comprising a lifting point ring 1, a flexible connector 2, a hanger 3, a bracket component 4, a support component 5, a handle component 6, a guide component 7, and a limit component 8; wherein:

[0055] The hanging point ring 1 is connected with the top of the flexible connector 2, and the flexible connector 2 is an iron chain, and there are four in total, and the bottom end of the flexible connector 2 is connected with the hanger 3.

[0056] The hanger 3 is a "day"-shaped frame formed by connecting five aluminum alloy connecting rods, and the air valve control box 9 for controlling each air valve and the air valve control box 9 for balancing the hanger are respectively installed on the hanger 3. The counterweight 10.

[0057] Described bracket assembly 4 comprises bracket 401, bracket connecting block 403, dead point clip 406, dead point clip connection pin 408, cylinder 409, cylinder fixed frame 410, guide frame 414...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap