Phosphorus coal pelletizing equipment for yellow phosphorus production

A technology for coal production and equipment, applied in the field of phosphorus coal ball production equipment, can solve the problems of unevenness, insufficient reaction reaction, decrease in reaction efficiency and heat utilization rate, etc., and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

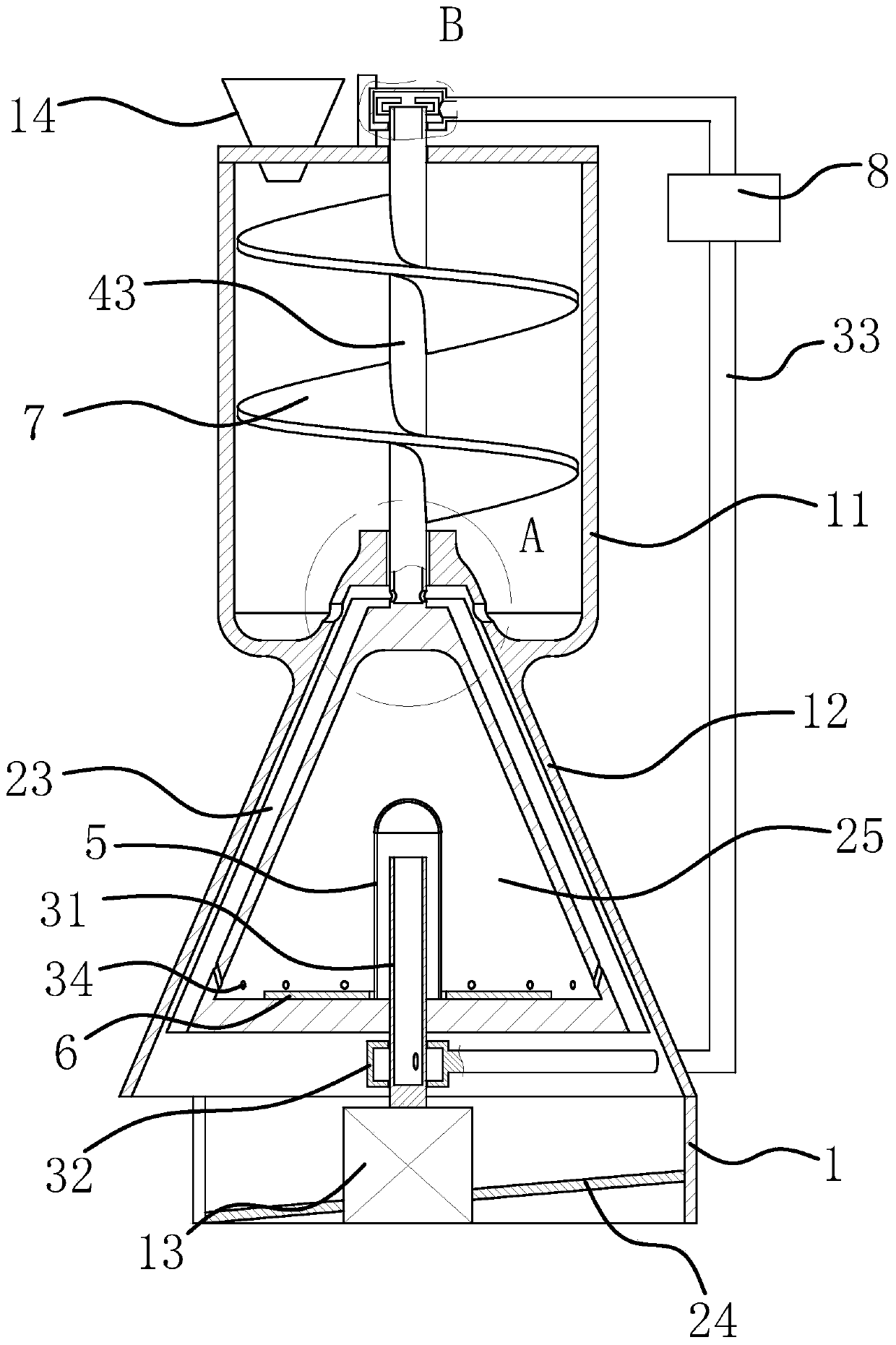

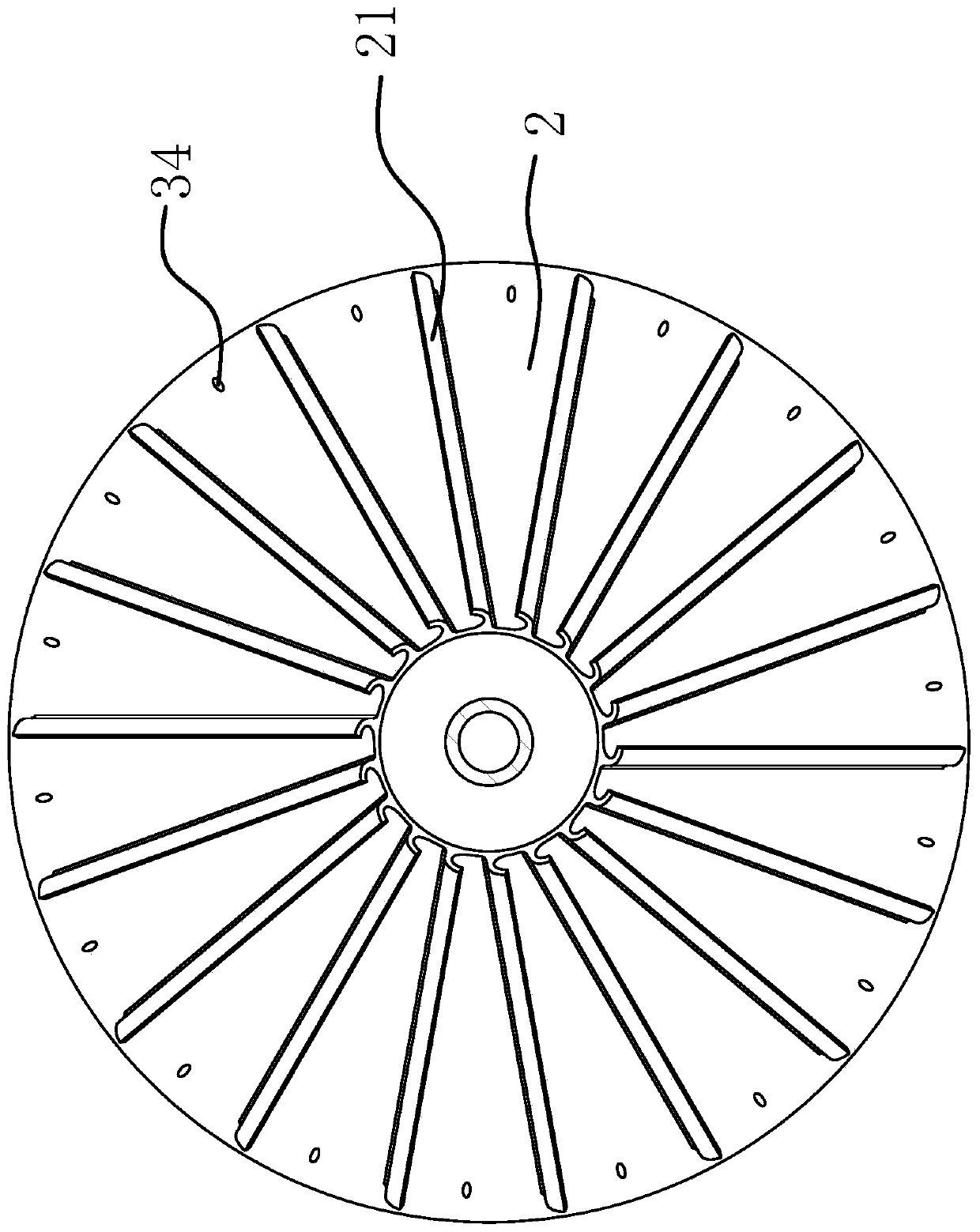

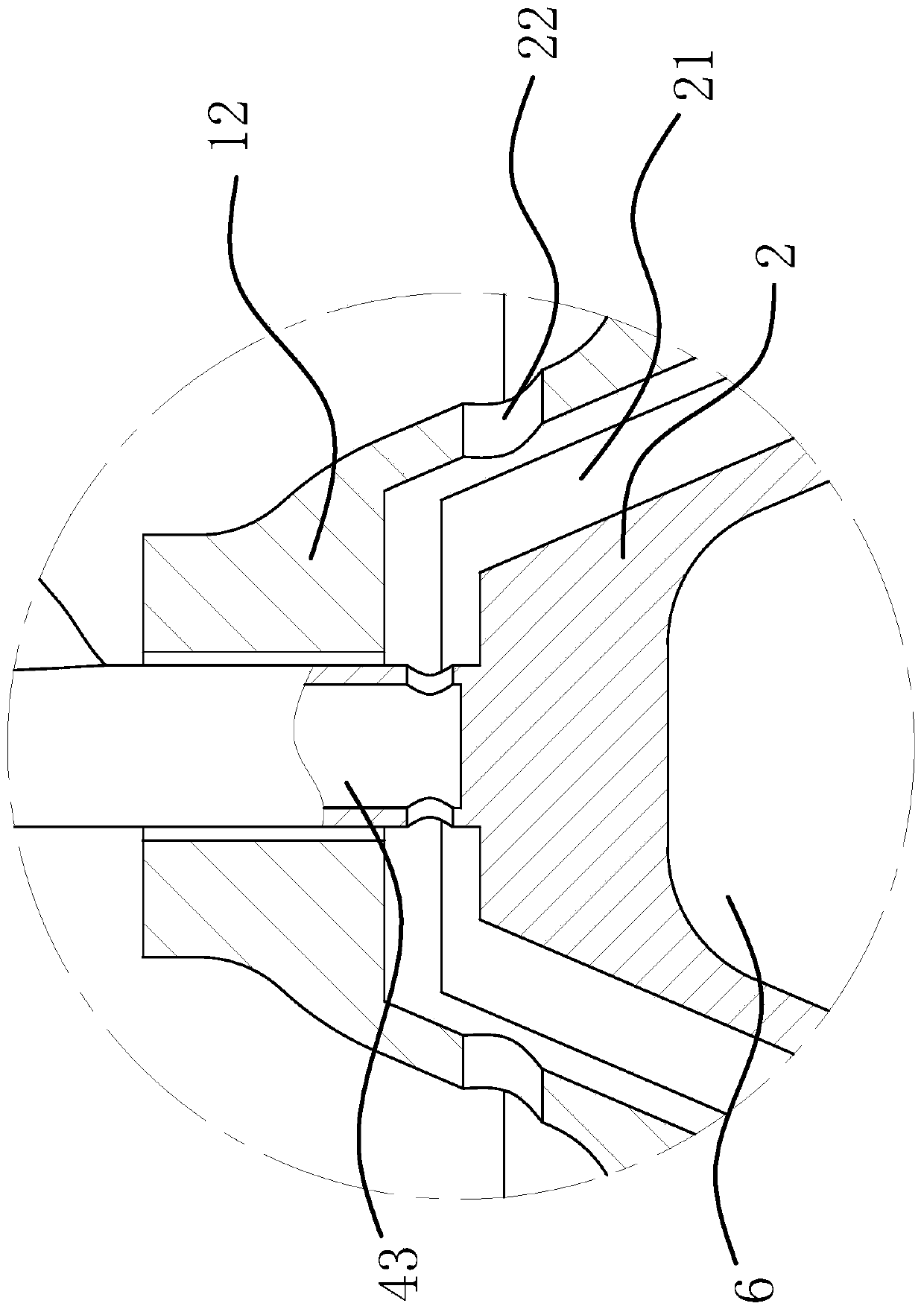

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the phosphate coal ball making equipment includes a machine base 1, a hopper 14, an extrusion barrel 11, a scraper drum 2 and a reduction motor 13. The lower end of the extrusion barrel 11 is fixedly provided with an outer shield 12, and the outer shield 12 is fixed. On the base 1, the scraping drum 2 is connected with the output shaft of the geared motor 13, and the housing of the geared motor 13 is fixed on the outer shield 12. The scraping drum 2 is tapered with a small diameter end facing upwards, and the outer shield 12 is sleeved outside the scraper barrel. The outer wall of the scraper barrel is evenly provided with a number of scrapers 21 in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap