Pre-stressed anchor cable combined ultrahigh composite reinforced soil abutment and construction method thereof

A technology of prestressed anchor cables and reinforced soil, which is applied in the direction of basic structure engineering, bridges, artificial islands, etc., can solve the problems of increased lateral soil pressure, decreased overall stability and anti-overturning ability of reinforced body structures, and reinforced soil Problems such as abutment slide, to achieve the effect of increasing the height, enhancing the overall stability and anti-overturning ability, and improving the overall stability and anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited to these embodiments, and all changes or equivalent substitutions that do not depart from the concept of the present invention are included within the protection scope of the present invention.

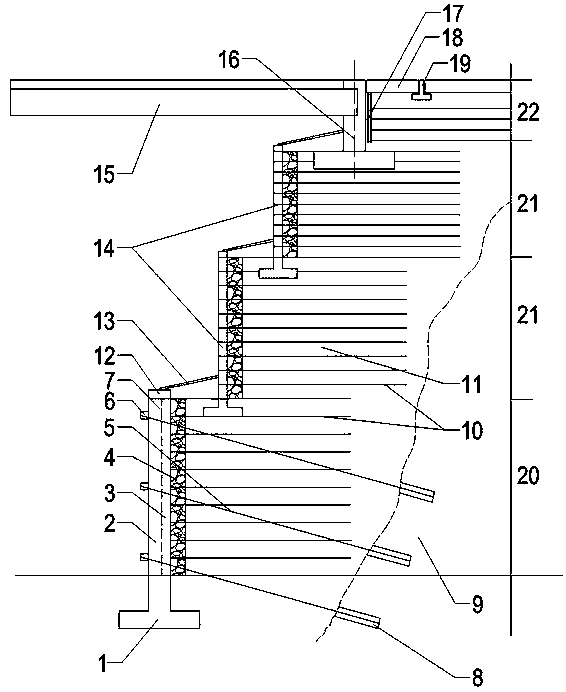

[0058] The ultra-high composite reinforced soil abutment combined with prestressed anchor cables includes the lowest abutment 20 leaning against the mountain 9, the uppermost abutment 22 and other abutments 21 at various levels.

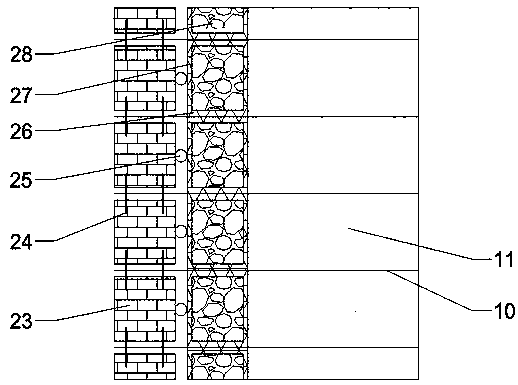

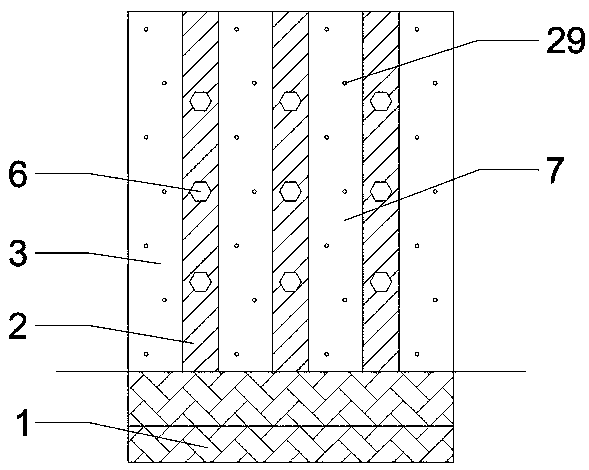

[0059] The lowermost abutment 20 includes a reinforced body structure constructed of several equally spaced geogrids 10 and wall fillers 11. The outer side of the geogrid 10 away from the side of the mountain body 9 is provided with an anti-filter layer 4, and the anti-filter layer 4 A retaining wall 7 is arranged on the outer side, a reinforced concrete cover beam 12 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com