Temporary prestress device for segmental prefabricated assembled beam

A prefabricated assembly and prestressing technology, which is applied in the direction of erecting/assembling bridges, bridges, joists, etc., can solve the problems of inconvenient installation, fixed positioning prestressed steel rope, inconvenient maintenance and installation, etc., to achieve convenient installation height and convenience The effect of maintenance installation and adjustment of installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

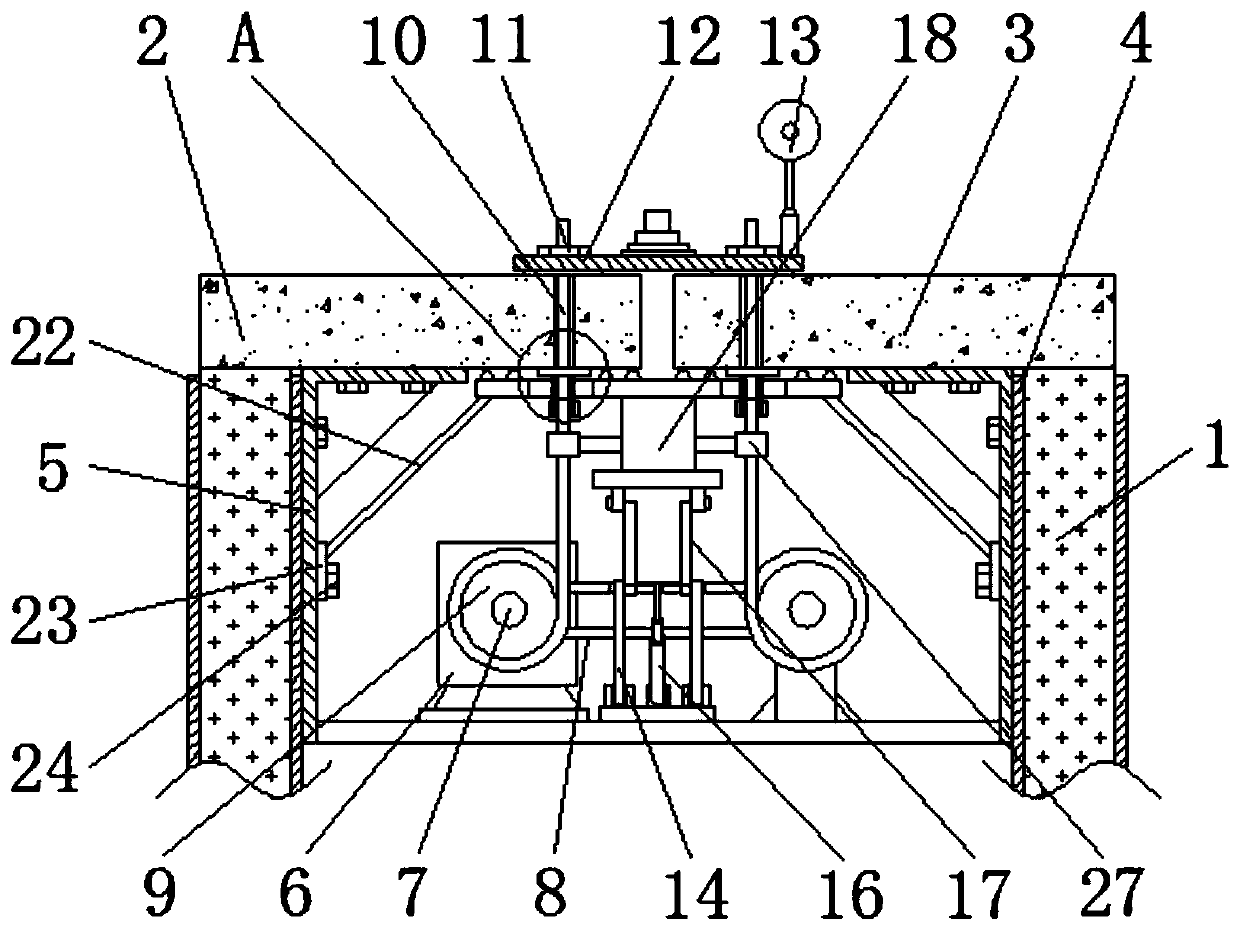

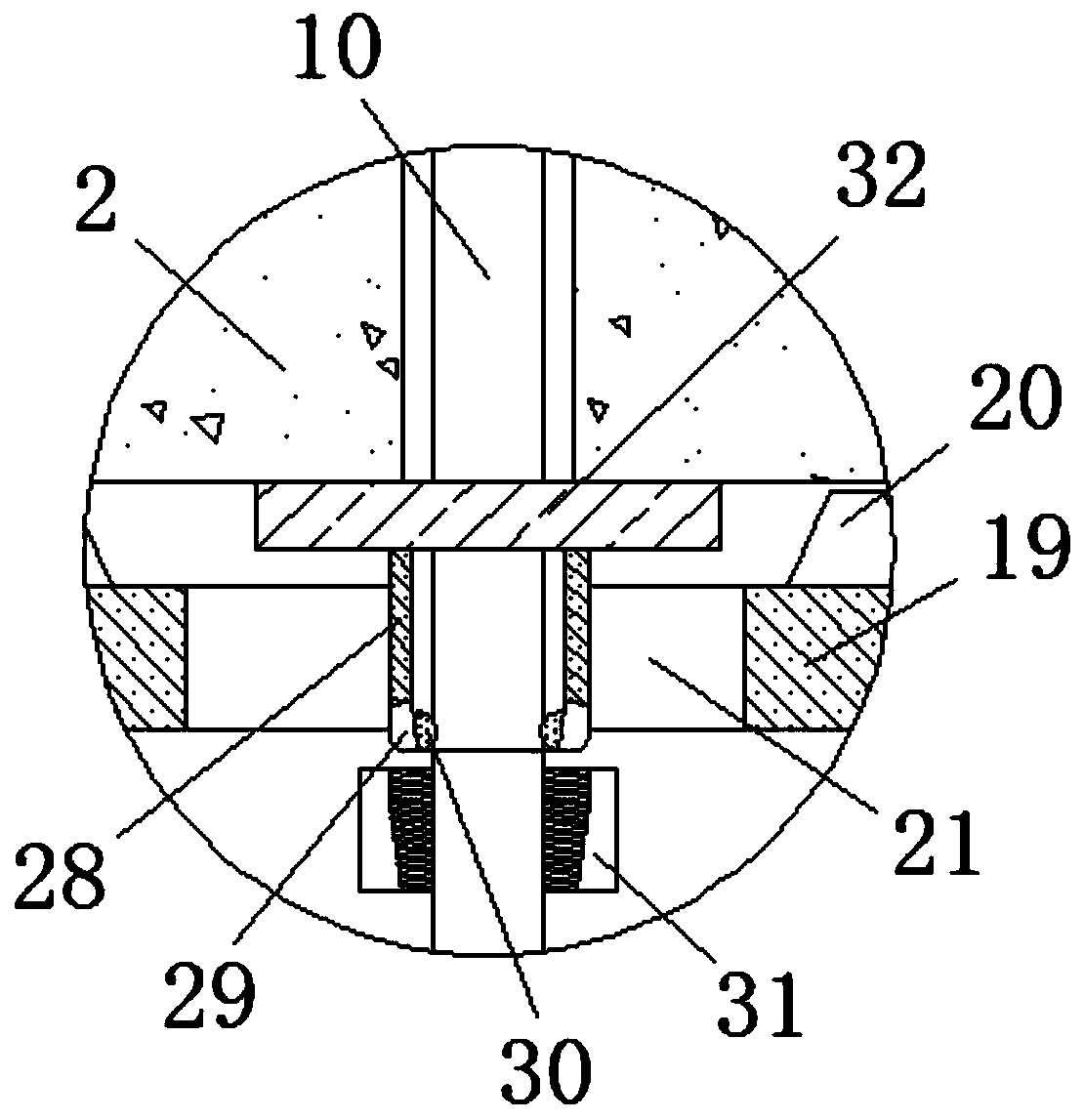

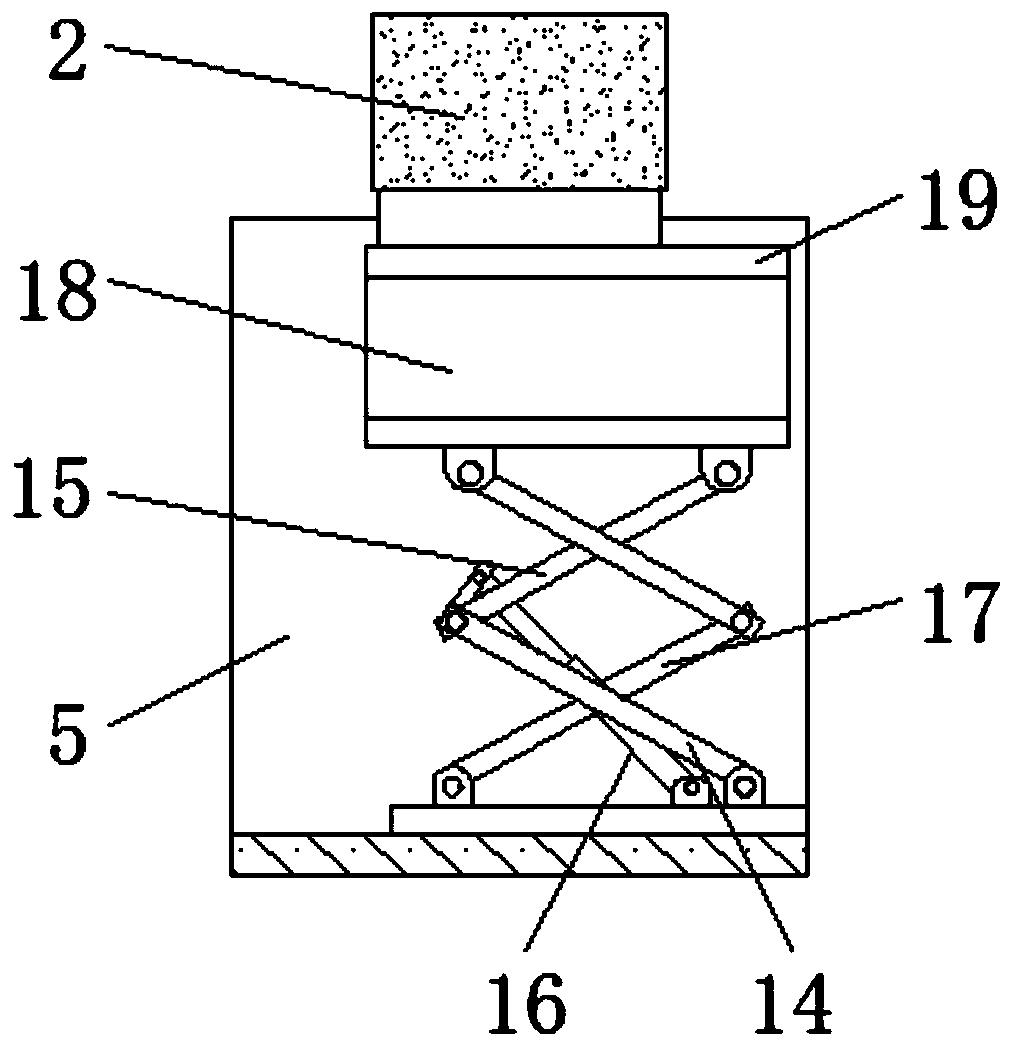

[0042] See Figure 1-7 , A temporary prestressing device for segmented prefabricated assembled beams, comprising a pouring column 1, a column template 4 and a drive motor 6. The top of the pouring column 1 is fixedly installed with a first segment prefabricated beam 2, and the first The right side of the segment prefabricated assembled beam 2 is connected with the second segment prefabricated assembled beam 3, the column template 4 is fixedly installed on the outer surface of the casting column 1, and the inner side of the column template 4 is fixedly installed with a mounting panel 5 to drive The motor 6 is fixedly installed on the upper side of the middle of the mounting panel 5, and the output end of the drive motor 6 is connected with an output shaft 7, the outside of the output shaft 7 is connected with a belt 8, and the front end of the output shaft 7 is fixedly installed with a winding shaft 9, and The outer surface of the winding shaft 9 is connected with a pre-stressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com