Cam coaxial sinusoidal motion mechanism and equipment adopting cam coaxial sinusoidal motion mechanism

A sinusoidal motion, camshaft technology, applied in mechanical equipment, machines/engines, transmissions, etc., can solve the problems of low mechanical efficiency and volumetric efficiency, high and low pressure return flow of cylinders, complex balancing mechanism, etc., to achieve compact structure and reduced noise. , the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

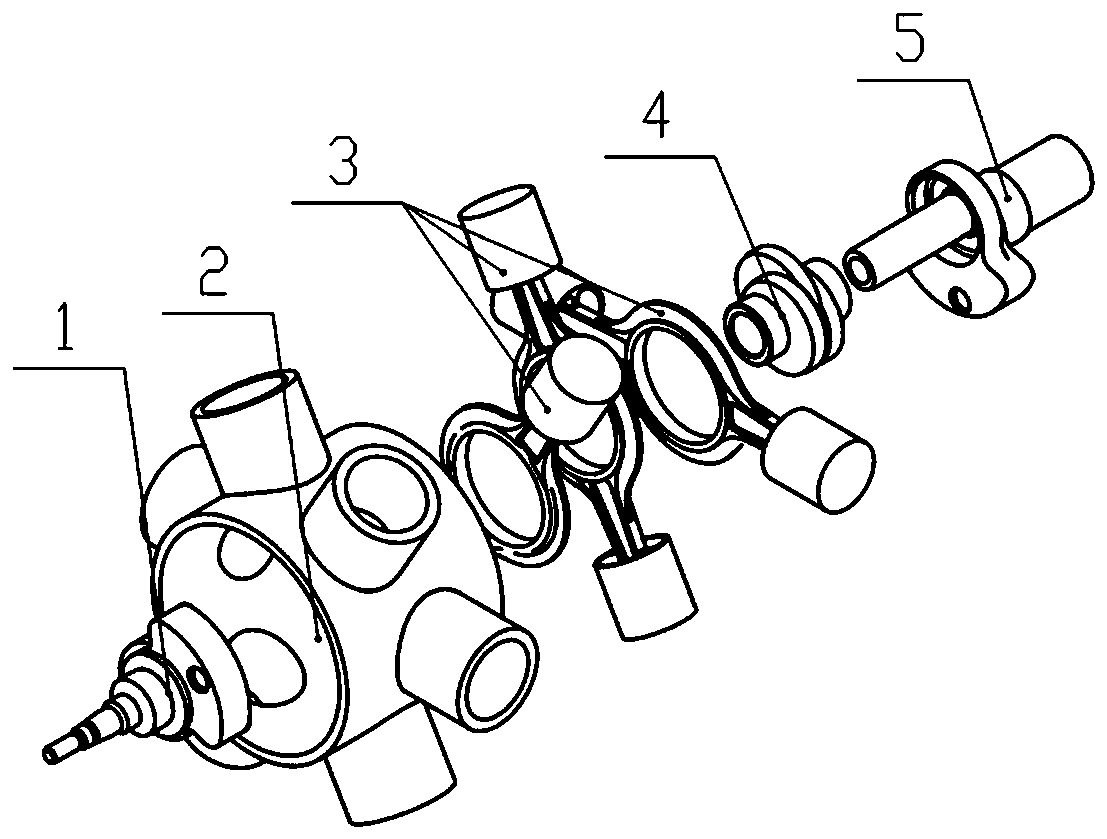

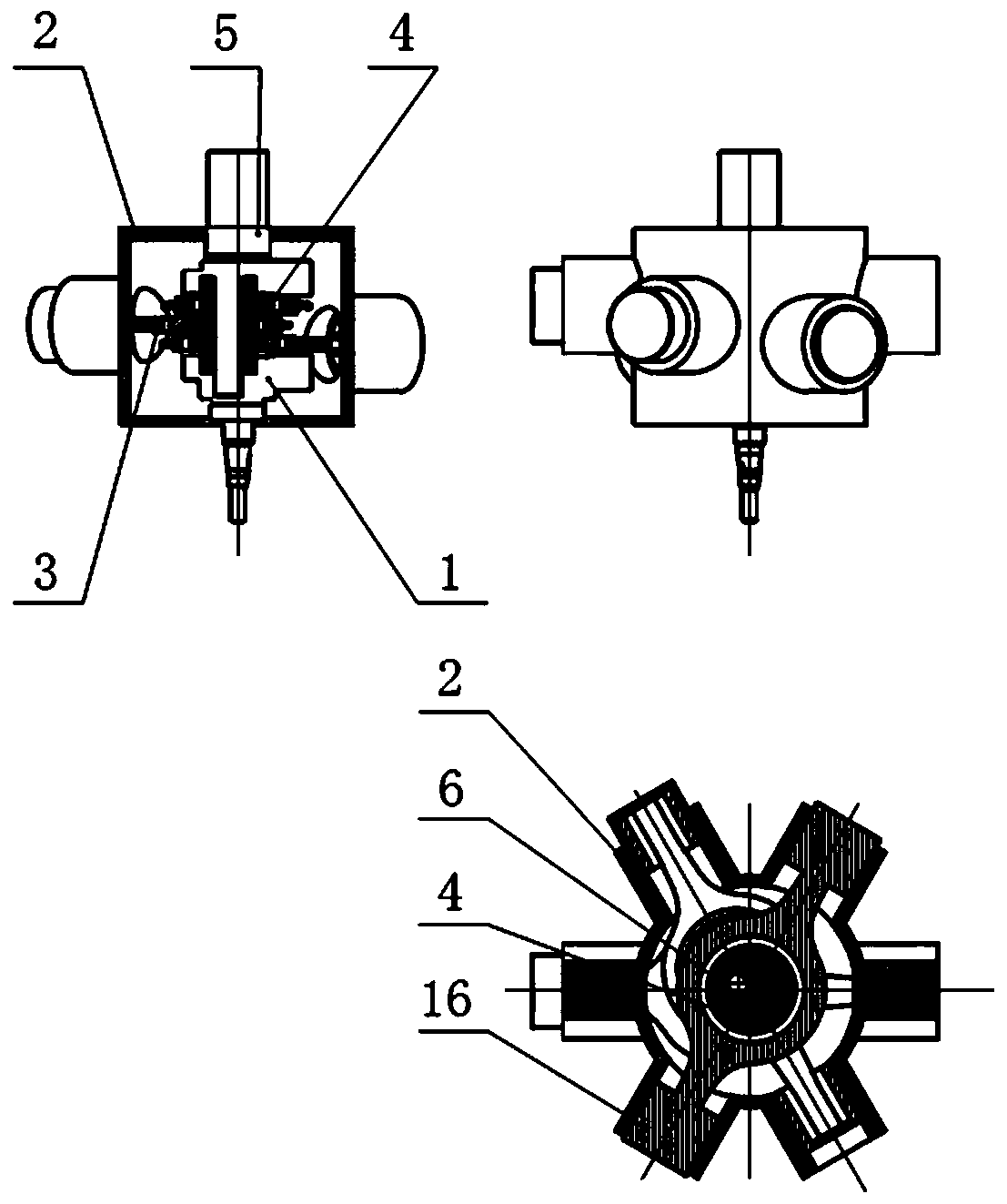

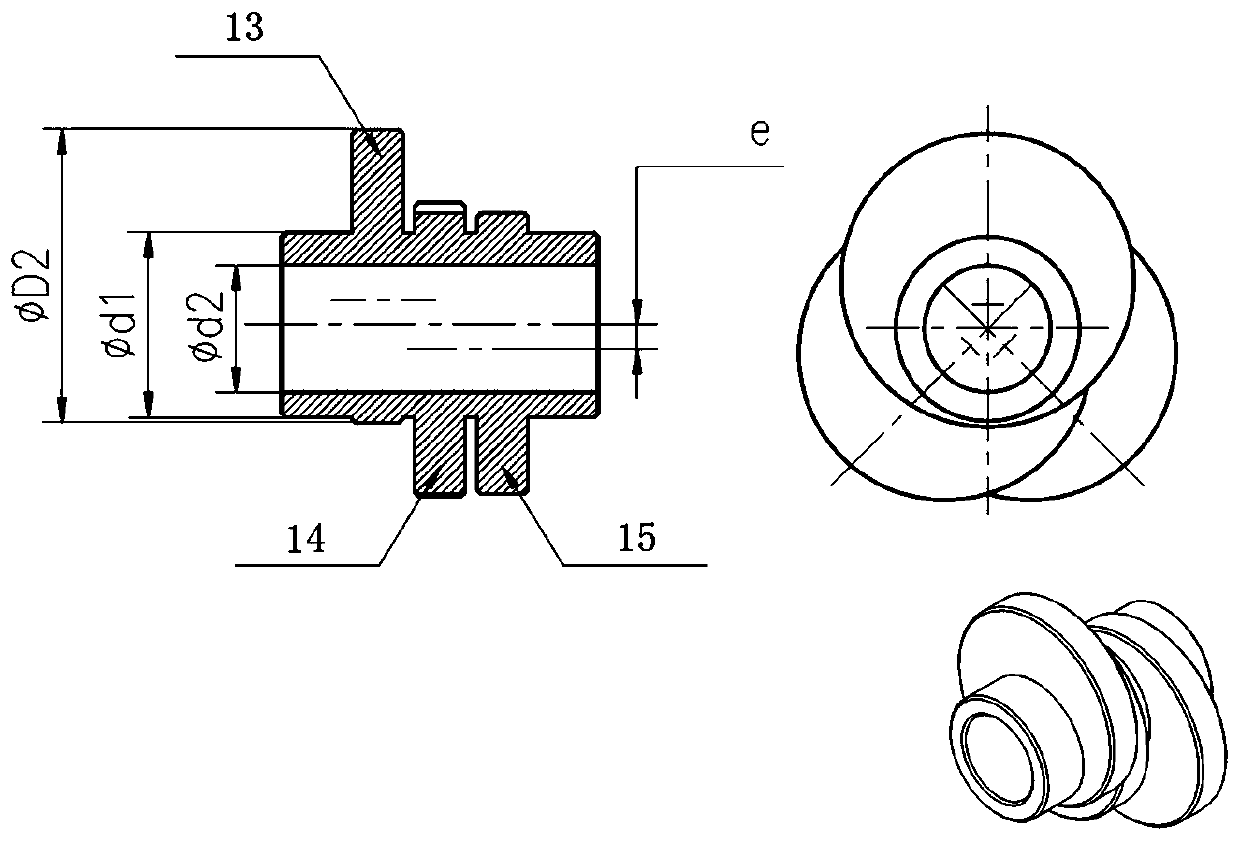

[0021] In this embodiment, the reciprocating rod is a piston rod, such as figure 1 As shown, the cam coaxial sinusoidal motion mechanism includes: eccentric circular camshaft 4, reciprocating rod 3, motion restraint body 2, crankshaft; crankshaft includes input-output shaft 5, crank (7, 11), crankshaft 1 and synchronous Axis 6. The eccentric circular camshaft 4 is sleeved on the synchronous shaft 6 of the input-output shaft 5 and is coaxial with the synchronous shaft 6. The synchronous shaft 6 is arranged between the two cranks and is fixedly connected with the cranks (7, 11); the reciprocating rod 3 can be The movement restrains the reciprocating linear motion in the body 2 . The motion-constrained body 2 is flexibly connected with the crankshaft 1 and the input-output shaft 5, and the crankshaft can rotate in the motion-constrained body. The crank (7, 11) and the eccentric circular camshaft 4 and the input-output shaft 5 form a combined crank camshaft component, and the ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com