Novel lubricating oil viscosity testing device

A technology of lubricating oil viscosity and testing equipment, which is applied in the direction of measuring equipment, indirect flow characteristic measurement, instruments, etc., can solve problems such as unfavorable engine state prediction, oil change cycle defects, oil performance differences, etc., to achieve independent measurement and improvement Identifying viscosity imprecise problems, the effect of ease of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

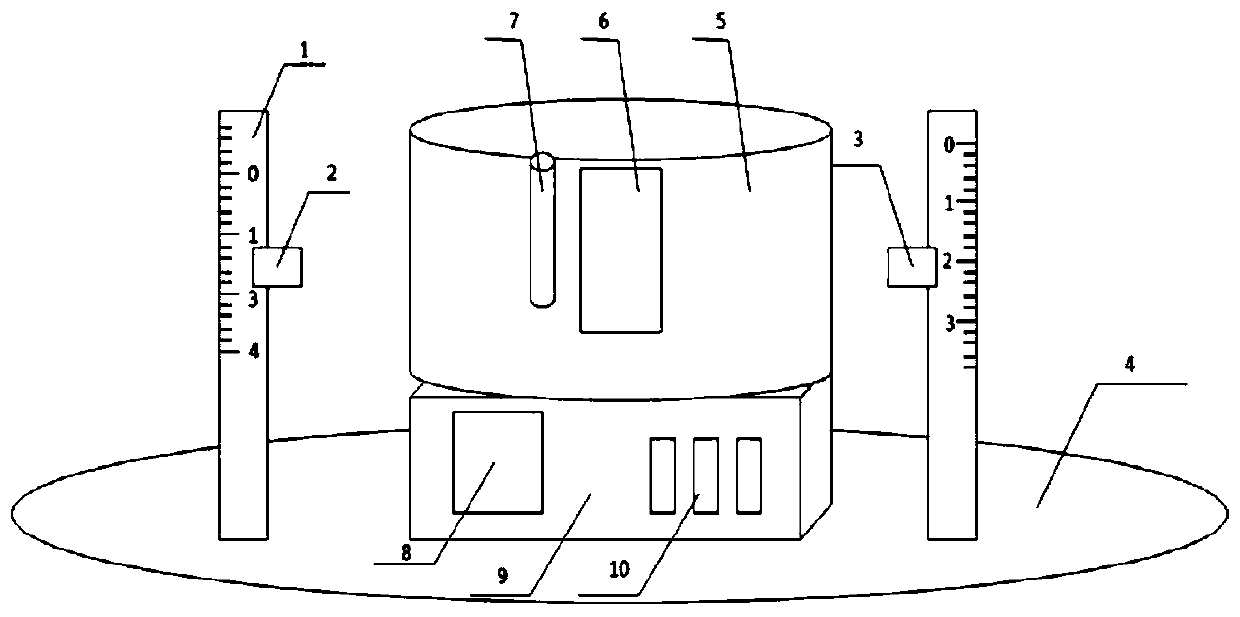

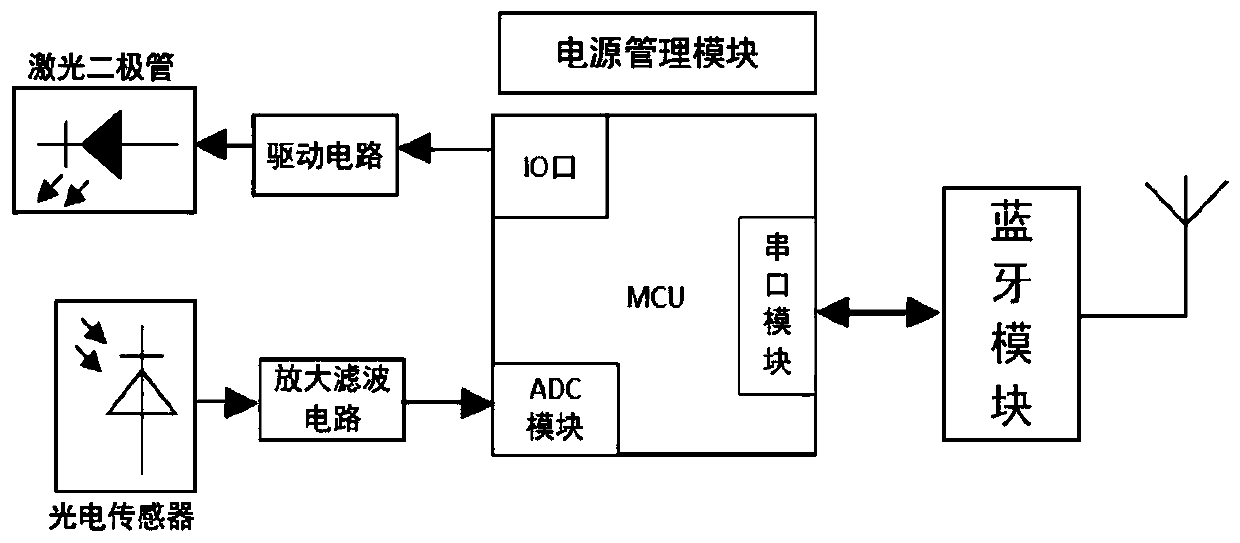

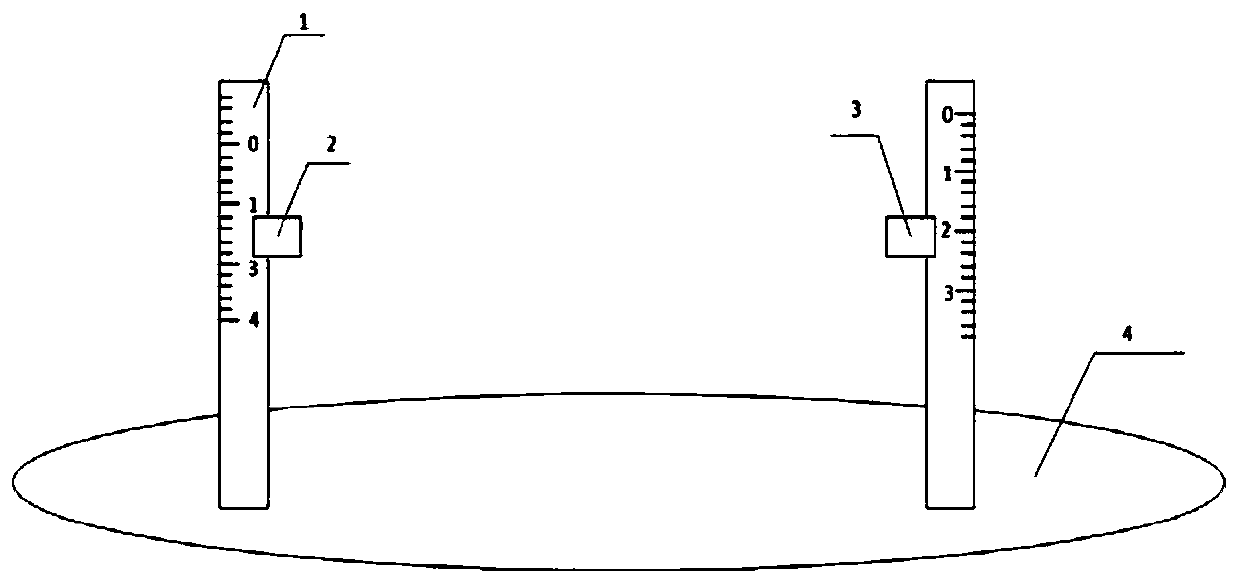

[0019] A new lubricating oil viscosity measurement device includes a petroleum product kinematic viscosity tester, a portable low-frequency small-signal photoelectric measurement system, and a metal experiment base. The petroleum product kinematic viscosity tester is a traditional petroleum product kinematic viscosity tester; the device includes a double-layer constant temperature bath, a stirrer, a thermocouple, a temperature electronic display screen, a control base, and a temperature control switch; the portable low-frequency small The signal photoelectric measurement system includes a photoelectric measurement device, a signal generating device, a signal receiving device, and an alarm system. The metal experiment base is connected with two parallel metal rods, and scales are engraved on the two metal rods at equal distances.

[0020] Further, the traditional kinematic vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com