Air bag sealing device for concrete test block penetration test

A concrete test block and air bag sealing technology, which is applied in the direction of measuring devices, engine sealing, permeability/surface area analysis, etc., can solve the problems of low sealing efficiency, long time consumption, and affecting test results, etc., to avoid rust and seal efficiency High, guaranteed sealing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

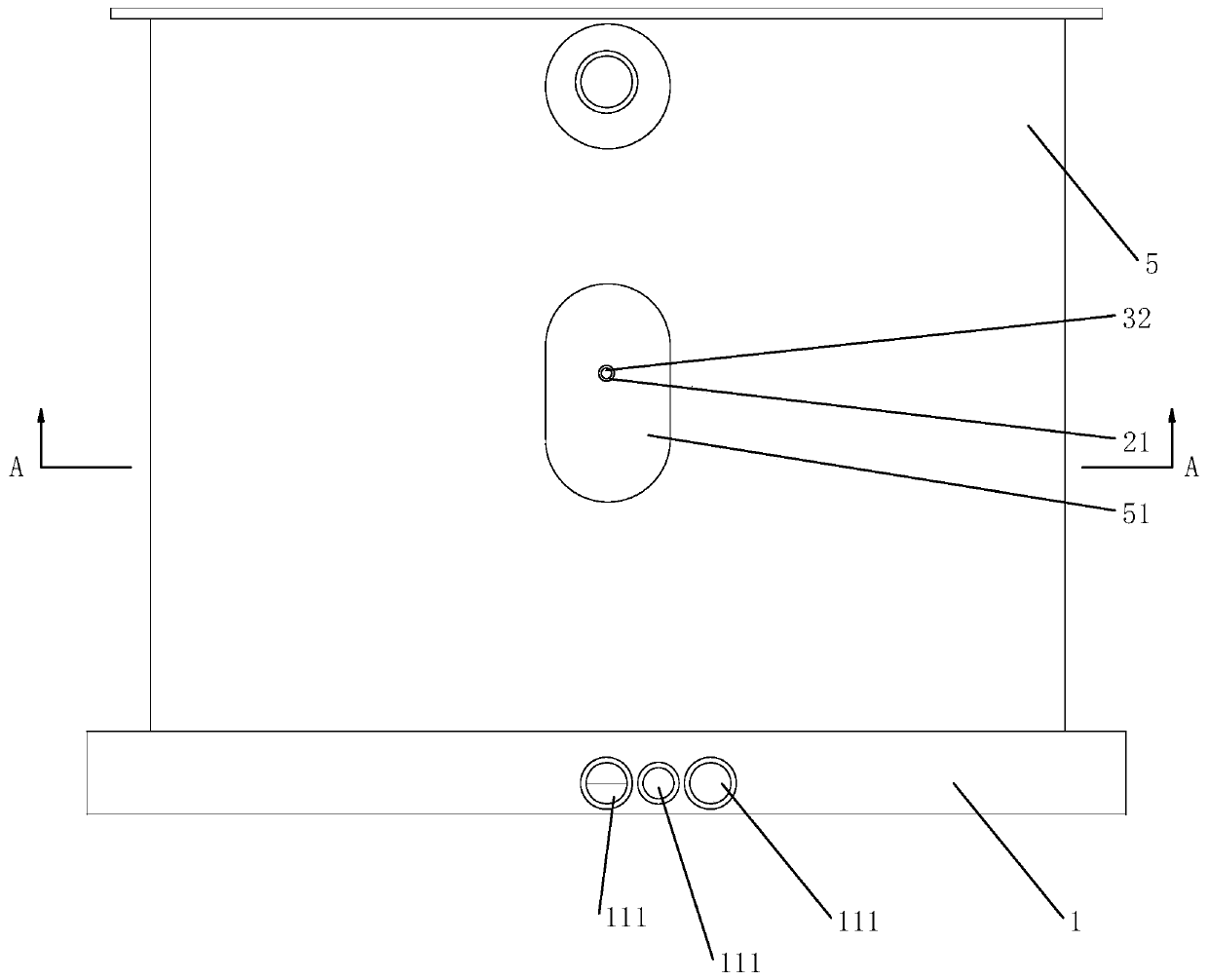

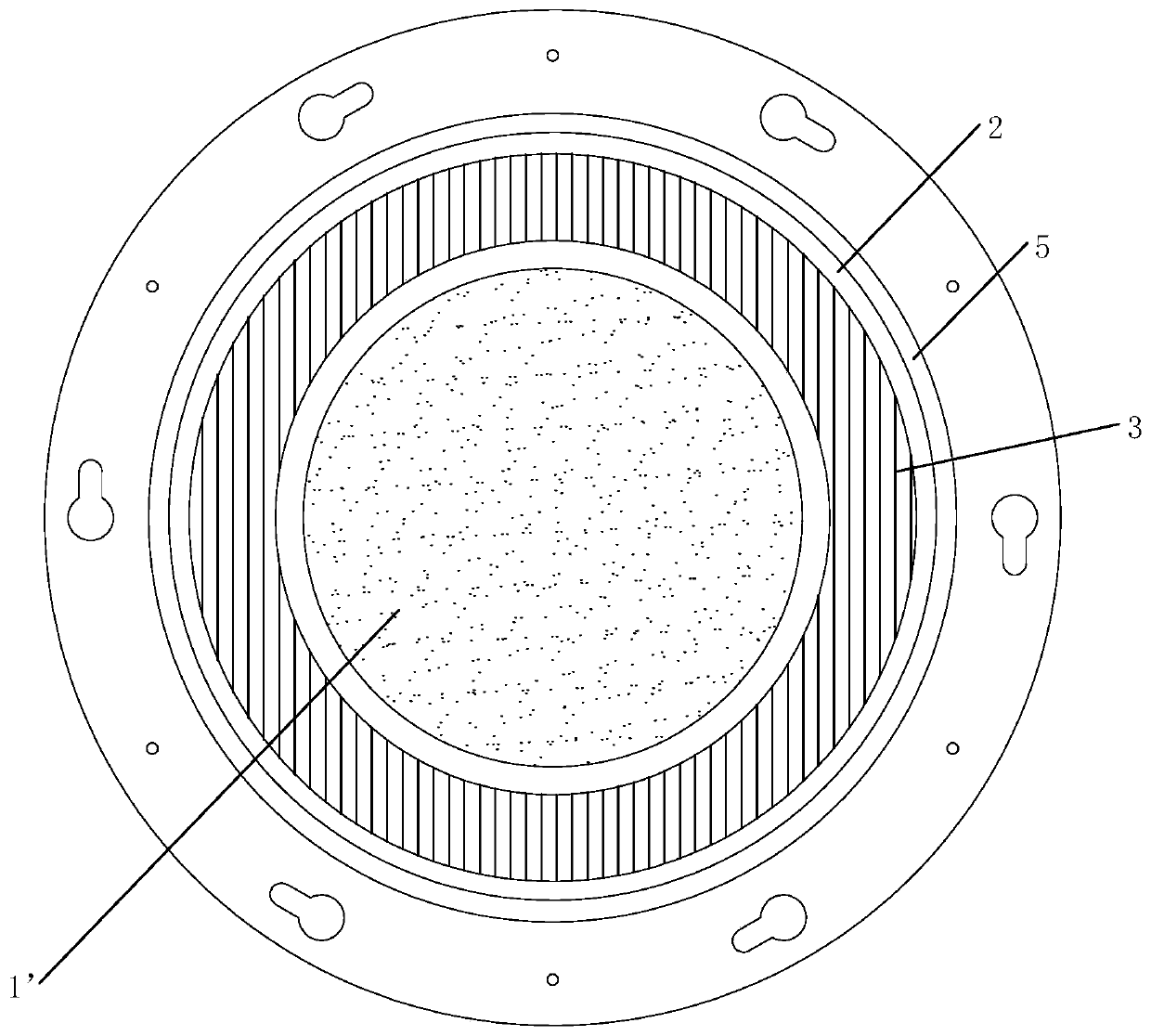

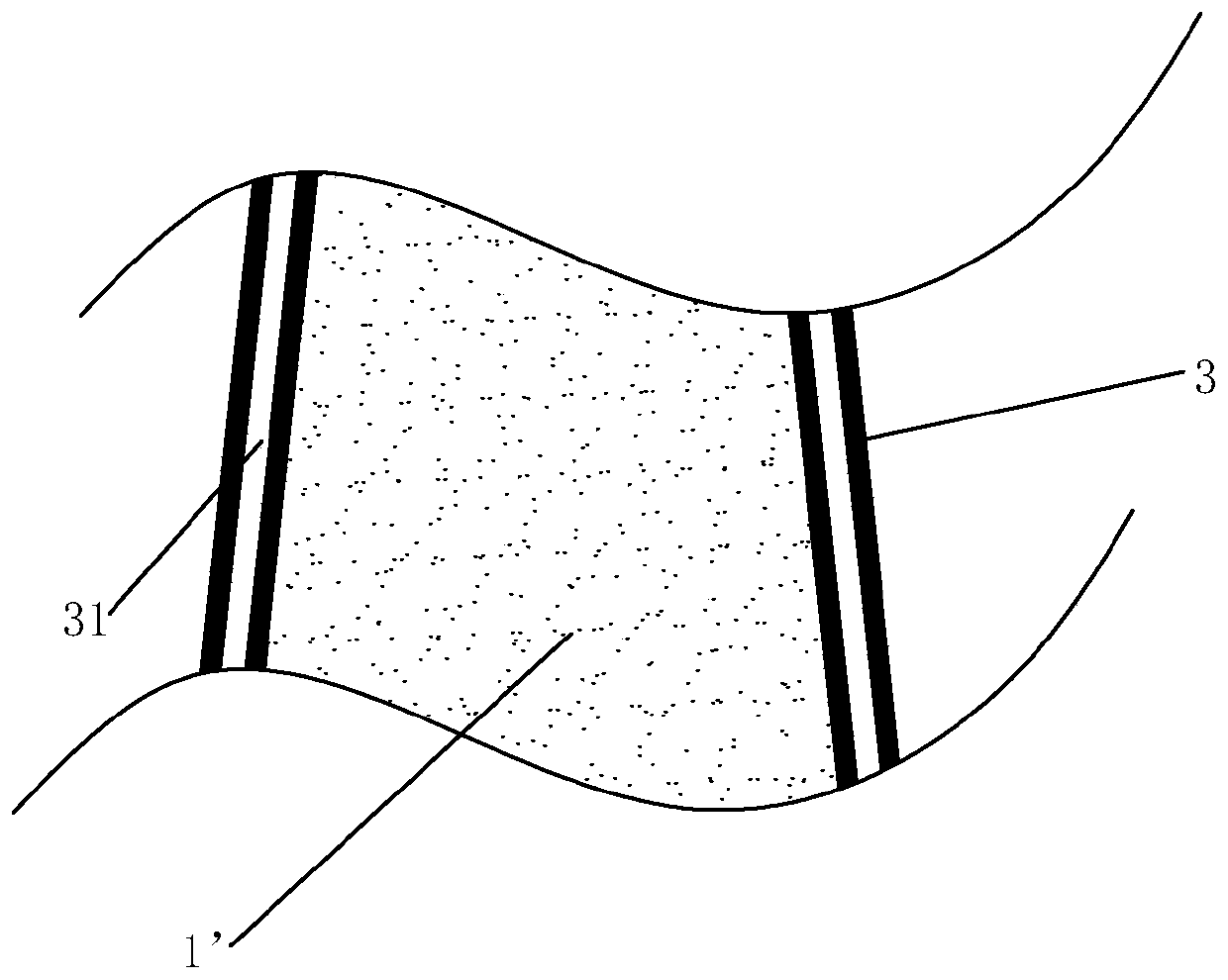

[0027] Such as figure 1 and figure 2 As shown, the air bag sealing device for the concrete test block penetration test of the present invention includes a base 1 for carrying the test block 1 ', a sleeve 2 mounted on the base 1, and a ring-shaped rubber cross-section mounted in the sleeve 2. The airbag 3, the upper cover 4 covered on the top of the sleeve 2, the metal shield 5, the height of the airbag 3 is higher than or equal to the height of the test block 1', and the inside of the airbag 3 has an inflatable cavity 31 (see image 3 ), a gap is reserved between the inner wall of the airbag 3 and the side of the test block 1' before it is inflated, such as image 3 As shown, after the airbag 3 is inflated, its inner wall is closely attached to the side of the test block 1 ', and the outer wall of the airbag 3 is provided with an inflation port 32 communicated with the inflation chamber 31. figure 1 , 2 , 4, 6, the side wall of the sleeve 2 is provided with an opening 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com