Aluminum plate material sharp edge corrosion test tool and method

A corrosion test, aluminum plate technology, applied in the analysis of materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems that cannot meet the requirements of the body, and the aluminum body cannot accurately express the corrosion situation, so as to achieve repeatability and reproduction Good performance, good sample consistency, and the same surface voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

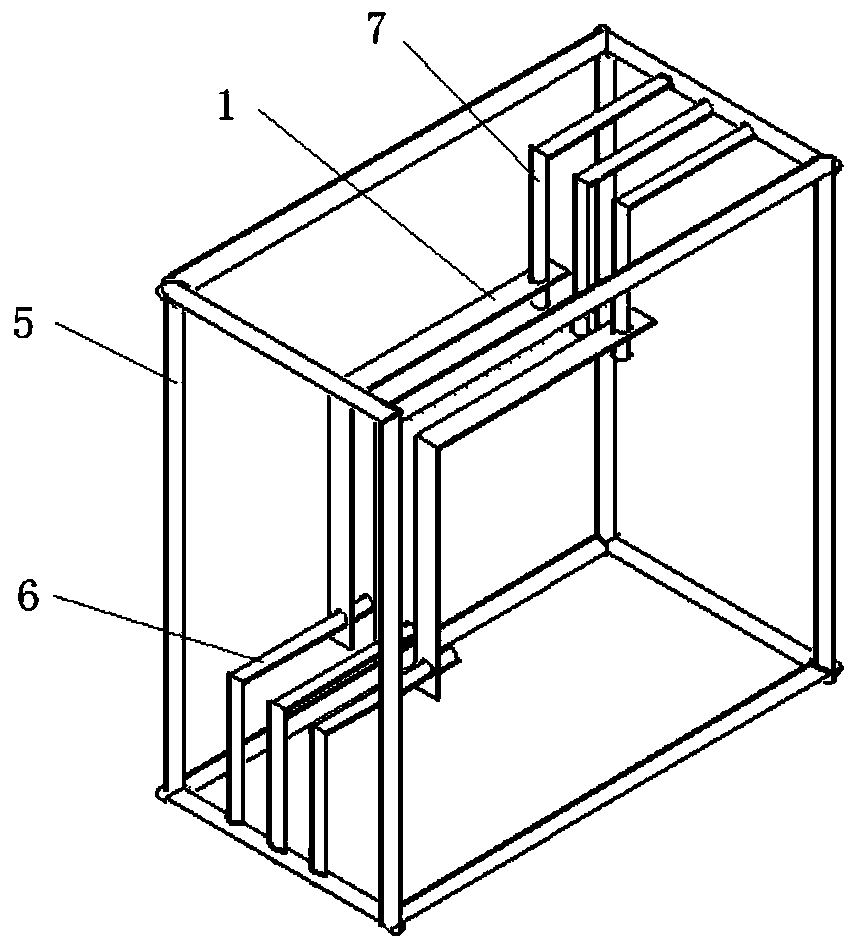

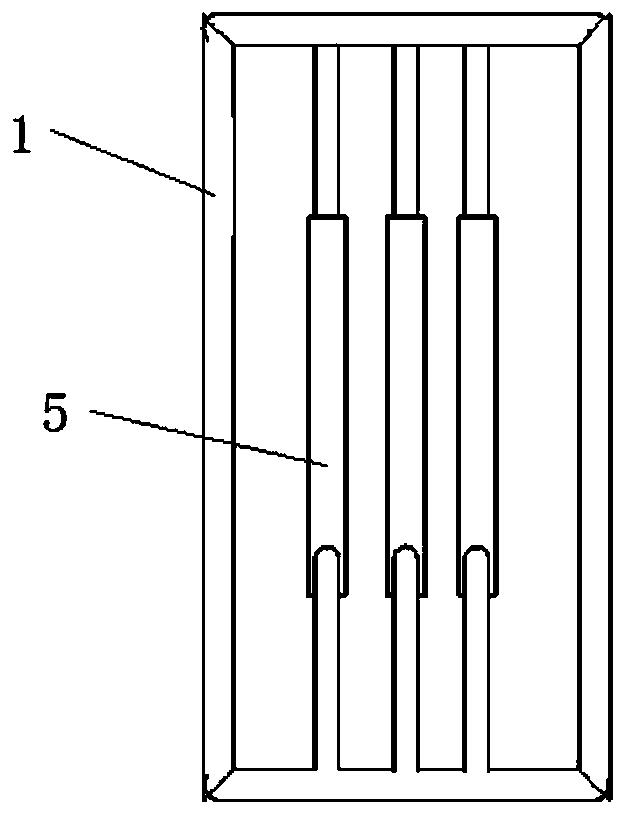

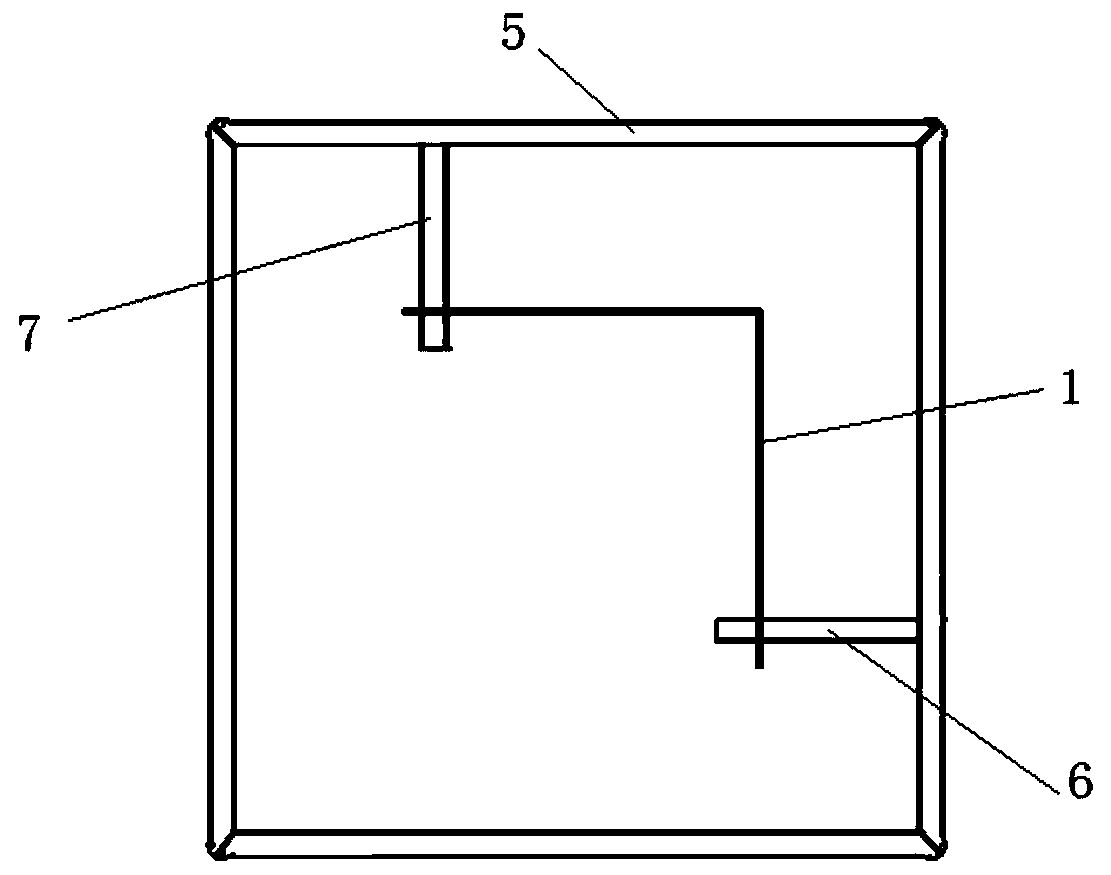

[0041] Such as Figure 1~3 As shown, the present application proposes a sharp-edged corrosion test fixture for aluminum plate materials, including a sample and a support frame.

[0042] The sample includes a right-angled sample piece 1, and one side edge of the sample piece 1 is provided with a slope. The two parts perpendicular to each other of the sample sheet 1 are A side 3 and B side 4, which respectively represent the elevation and plane of the car body during the electrophoresis process. The slope is C surface 2, which represents the sharp edge of the vehicle body, and is gradually thinned from the set distance from the edge of sample 1 to the edge of sample 1. Multiple samples 1 can be set, and multiple samples 1 are arranged horizontally on the support frame. Different samples 1 are made of aluminum plates of different grades, which can realize the test of different body parts.

[0043] The support frame includes a cube frame 5 , a transverse support rod 6 and a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com