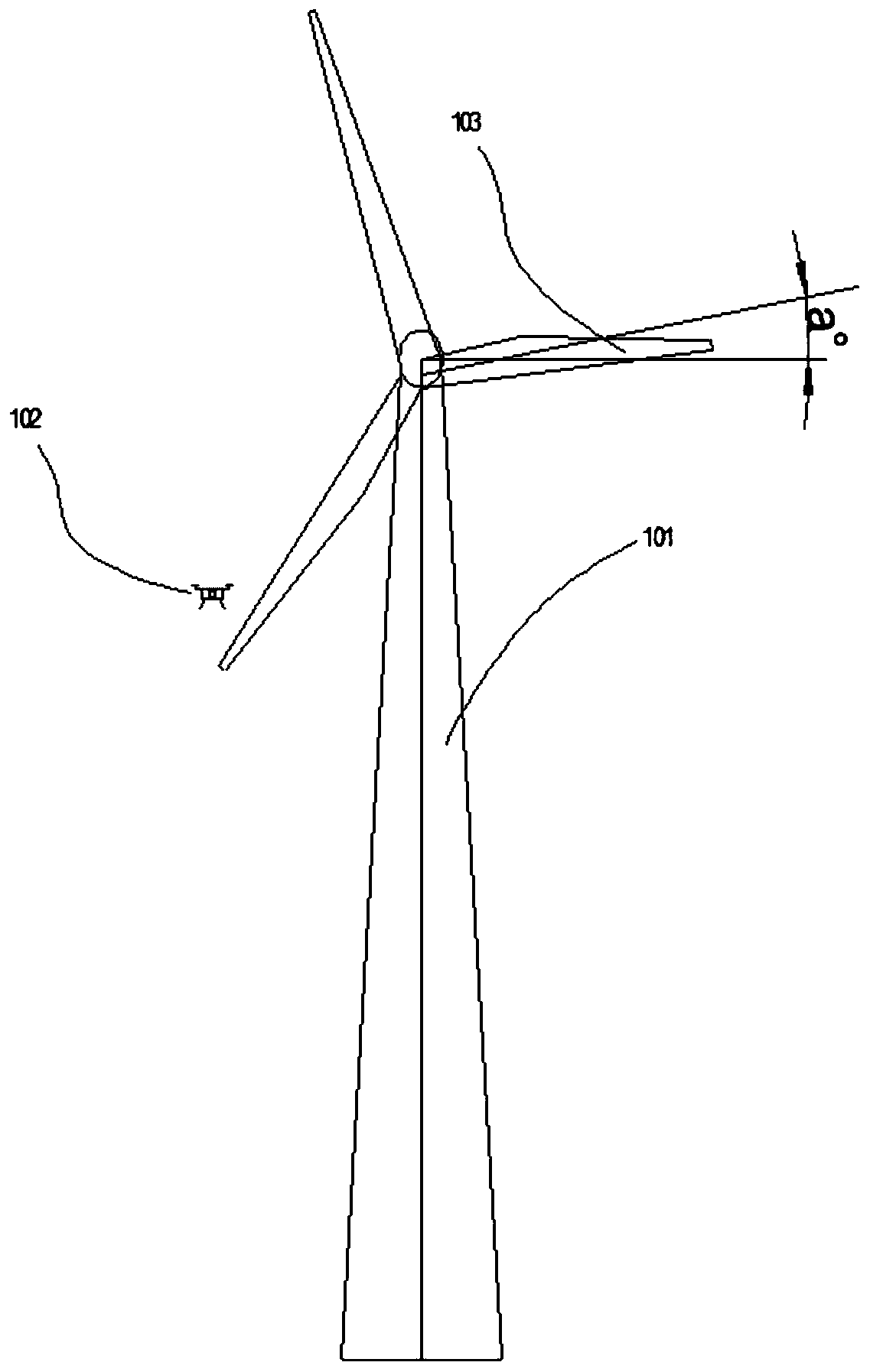

Wind turbine blade outfield unmanned aerial vehicle double-light-source detection system and method

A technology for wind turbine blades and inspection systems, applied in wind turbines, monitoring of wind turbines, and optical testing for flaws/defects, etc. It can solve problems such as time-consuming and labor-intensive, quality awareness is greatly affected, and inspections cannot be done in place, so as to achieve low safety risks. , comprehensive inspection, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

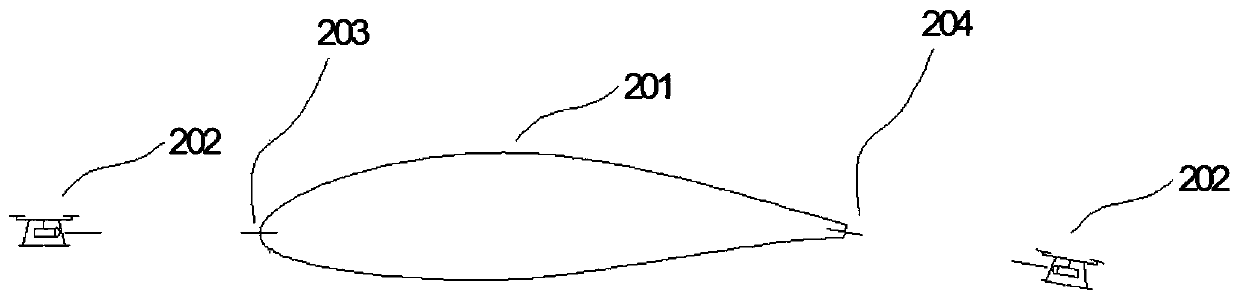

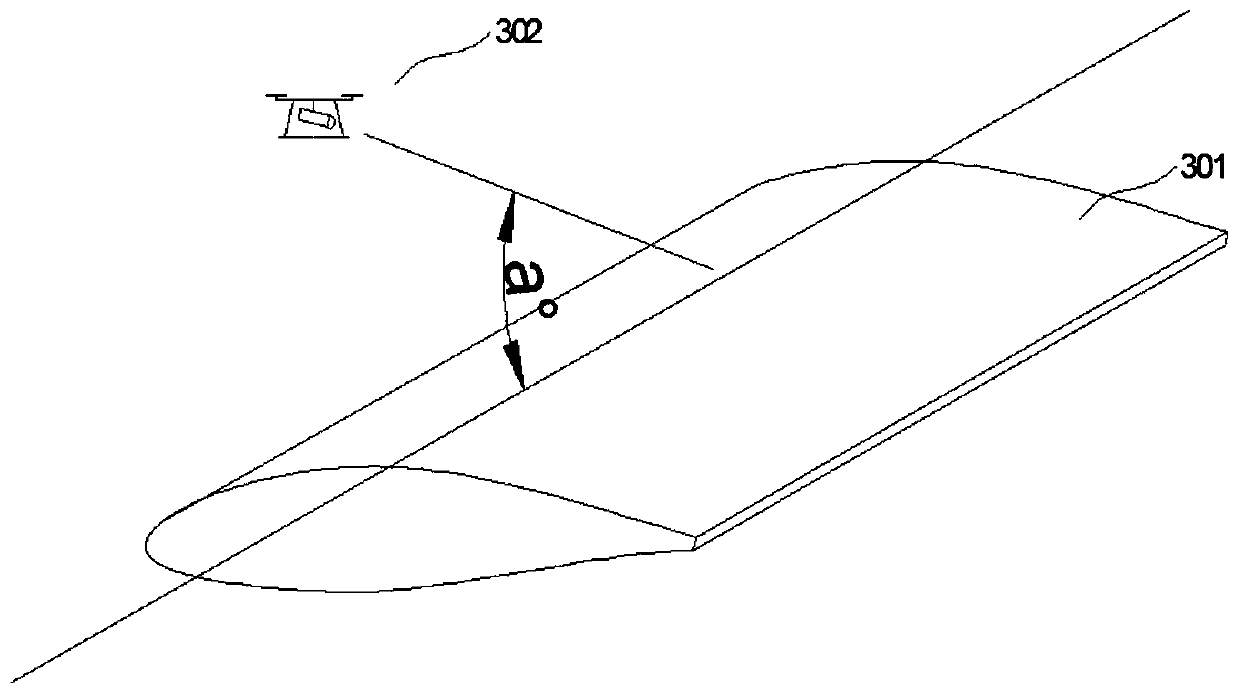

[0029] The invention provides a blade inspection system with dual light sources, including a drone, a visible light high-definition camera, an infrared camera, and a processing terminal installed with supporting software for image data processing. Wherein, the processing terminal may be a PC, a pad, a mobile phone, and the like.

[0030] Specifically, the UAV is equipped with a dual gimbal system, that is, it carries a visible light high-definition camera and an infrared light camera at the same time. During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com