A single-mode single-polarization hollow-core negative-curvature optical fiber

A single-polarization, negative curvature technology, applied in cladding fibers, light guides, optics, etc., to achieve the effects of enhanced energy exchange capability, simple structure, and obvious leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Taking the working wavelength of 2940nm as an example, the inventive principle is also applicable to each wavelength.

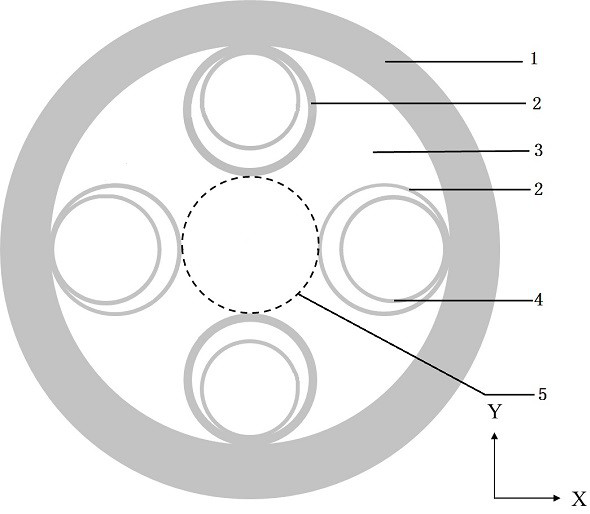

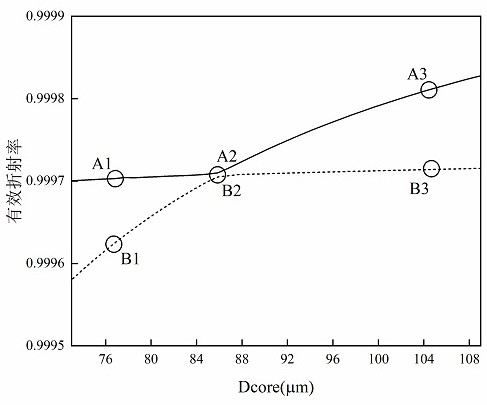

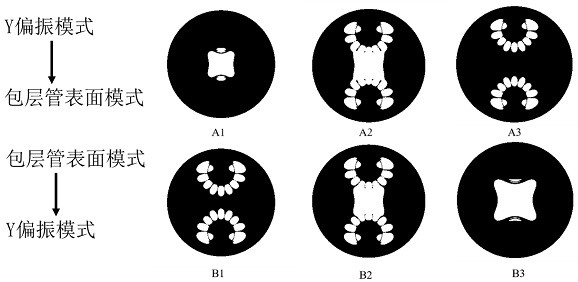

[0035] like figure 1 As shown, the relevant parameters of the single-mode single-polarization hollow-core negative-curvature fiber are as follows: the diameter of the core 5: 85.86 μm; the outer diameter of the cladding tube 2: 91.14 μm; the thickness of the quartz glass capillary of the nesting tube 4 and the cladding tube 2 in the X direction : 0.743 μm; Y-direction cladding tube 2 quartz glass capillary thickness: 1.60 μm; the maximum distance between the outer wall of each nested tube 4 and the cladding tube 2 inner wall: 11.76 μm; the effective mode field area is greater than 3000 [μm^2]; X polarization mode loss: 2.8×10-2dB / m; Y polarization mode loss: 57.5dB / m; High-order mode minimum loss: 3.7dB / m; Single polarization suppression ratio: 2037; High-order mode suppression ratio: 129; Birefringence difference: 1.4 ×10 -5 .

[0036] like figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com