End plate wire fixer

A wire fixer and end plate technology, applied in the direction of electrical components, connections, clamping/spring connections, etc., can solve problems such as poor contact between wires and wire clamps, unsteady tightening torque, and ineffective compression of wires. Achieve the effect of saving process, reducing processing cost and stabilizing tightening torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] It should be noted in advance that in the present invention, unless otherwise specified and limited, the terms "installation", "connection", "connection", "fixation" and other terms should be understood in a broad sense, for example, it can be a fixed connection, It can also be detachably connected or integrally connected; it can be directly connected or indirectly connected through an intermediary, and it can be internal communication between two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

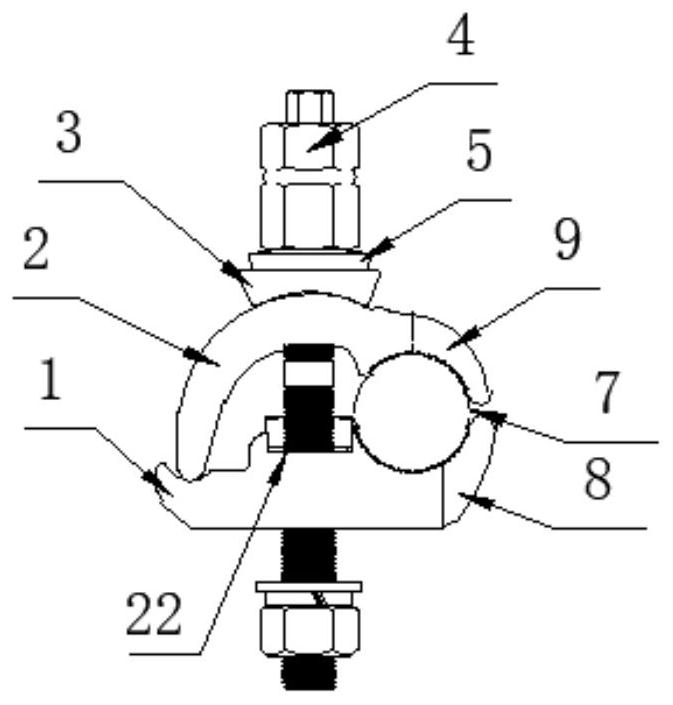

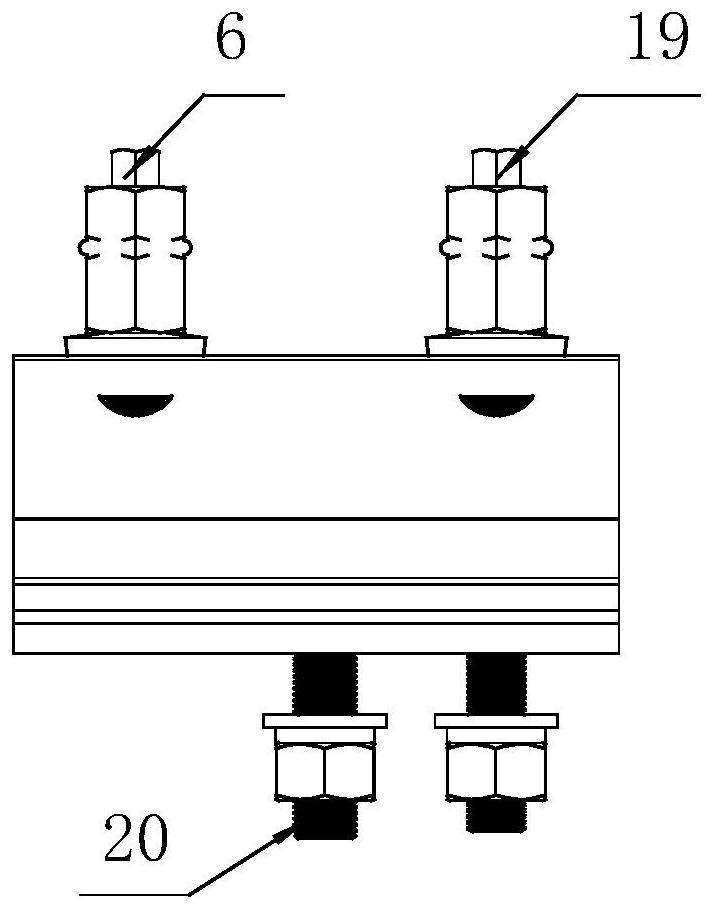

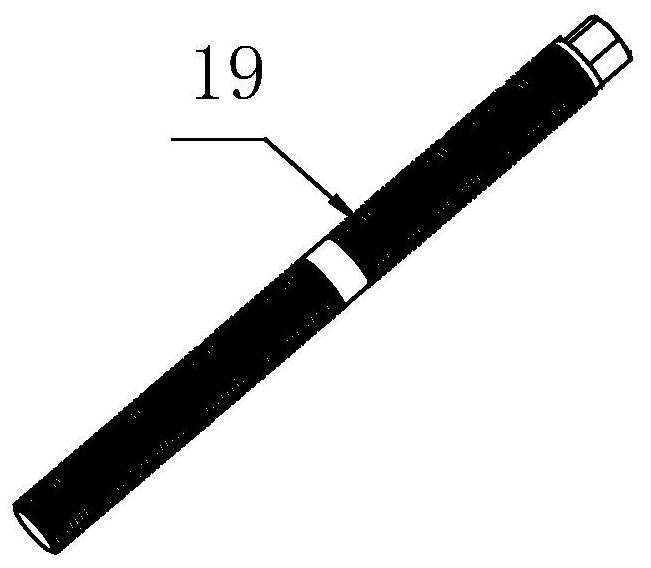

[0033] like Figure 1-Figure 9As shown: this embodiment provides an end plate wire fixer, which includes an upper splint 2, a lower splint 1 and a bolt connection assembly that are fastened to each other. The lower surface of the lower splint 1 is directly in contact with the surface of the end plate 25 of the electrical equipment One side of the upper splint 2 and...

Embodiment 2

[0039] The main difference from Embodiment 1 is that the threaded hole 24 connected to the third screw 6 is processed as a through hole, and the lower part of the through hole needs to be provided with a protrusion capable of blocking and lifting the third screw. The raised portion can be realized by a size variation of the aperture or a difference in the shape of the aperture.

Embodiment 3

[0041] The main difference from Example 1 is that the first screw and the third screw adopt a stepped shaft shape with a large top and a small bottom, that is, the outer diameter of the lower threaded part of the first screw and the third screw is smaller than that of the upper part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com