Staggered bonding metal circuit

A metal circuit and interleaving technology, which is applied in the direction of printed circuit, printed circuit manufacturing, printed circuit assembly of electric components, etc., can solve problems such as abnormal operation, large use limitations, and reduced product area, so as to save bonding space, The effect of simple modification and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

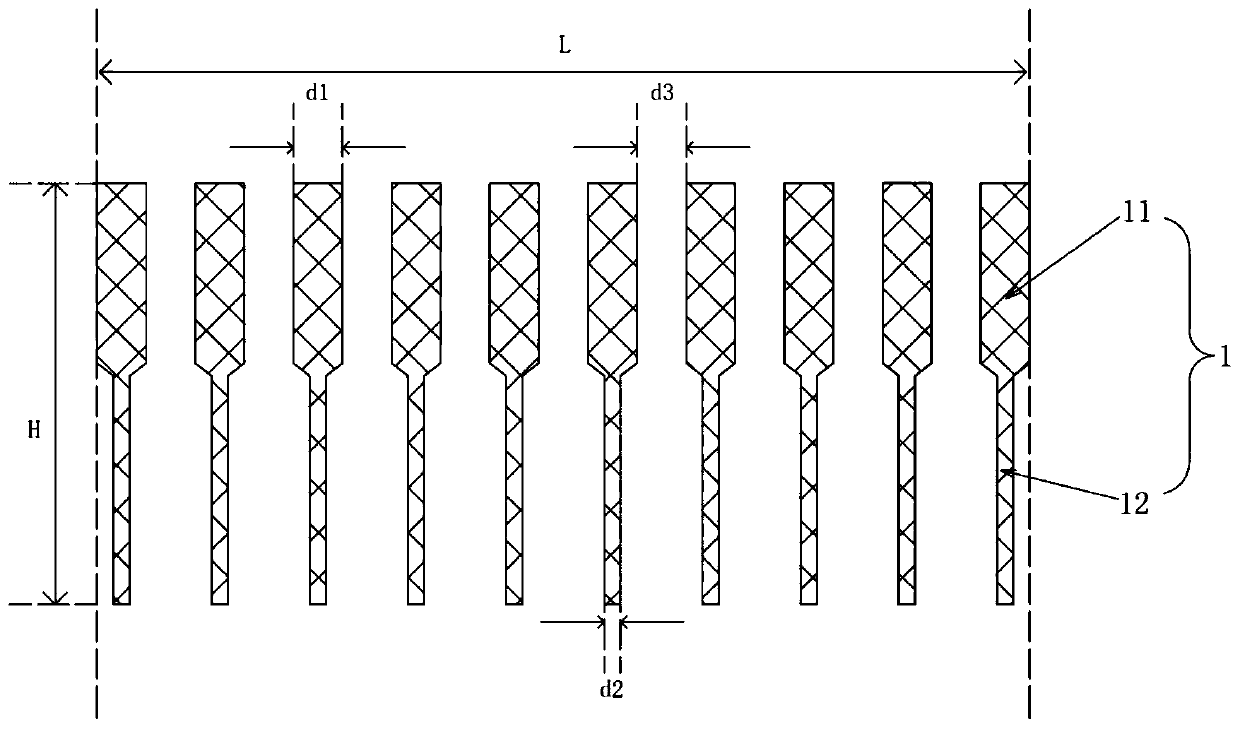

Embodiment 1

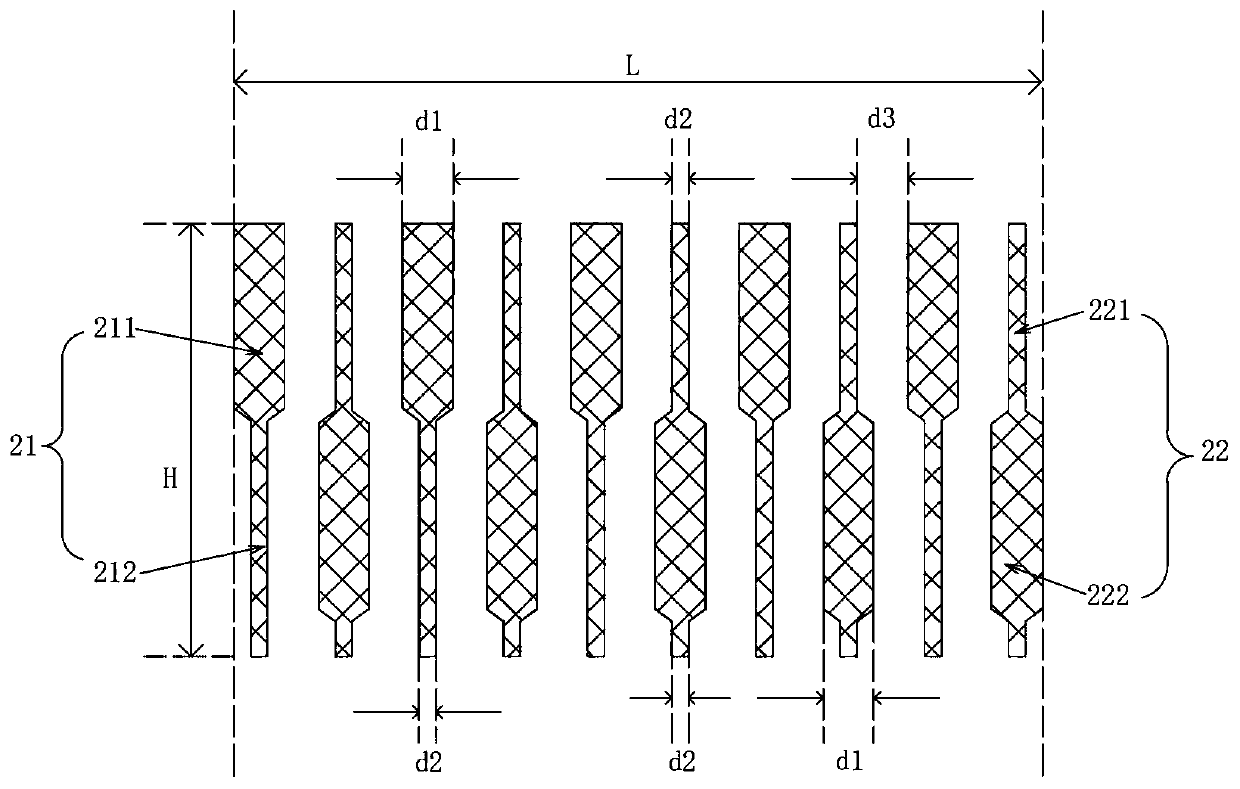

[0036] Embodiment 1: as the description attached figure 2 As shown, the first wide channel 211 and the second wide channel 222 are staggered, the first narrow channel 212 and the second narrow channel 221 are staggered, the line widths of the first wide channel 211 and the second wide channel 222 are equal, and the first wide channel 211 and the second wide channel 222 have the same line width. The line width of a narrow channel 212 and the second narrow channel 221 is equal, the first wide channel 211 and the second wide channel 222 are a single rectangle, the first narrow channel 212 and the second narrow channel 221 are strips, and the first narrow channel 212 The connection is arranged at the bottom of the first wide channel 211 and the connection is provided with a bevel transition, the second wide channel 222 is connected at the non-end point of the second narrow channel 221 and the connection is provided with a bevel transition, the first narrow channel The 212 connect...

Embodiment 2

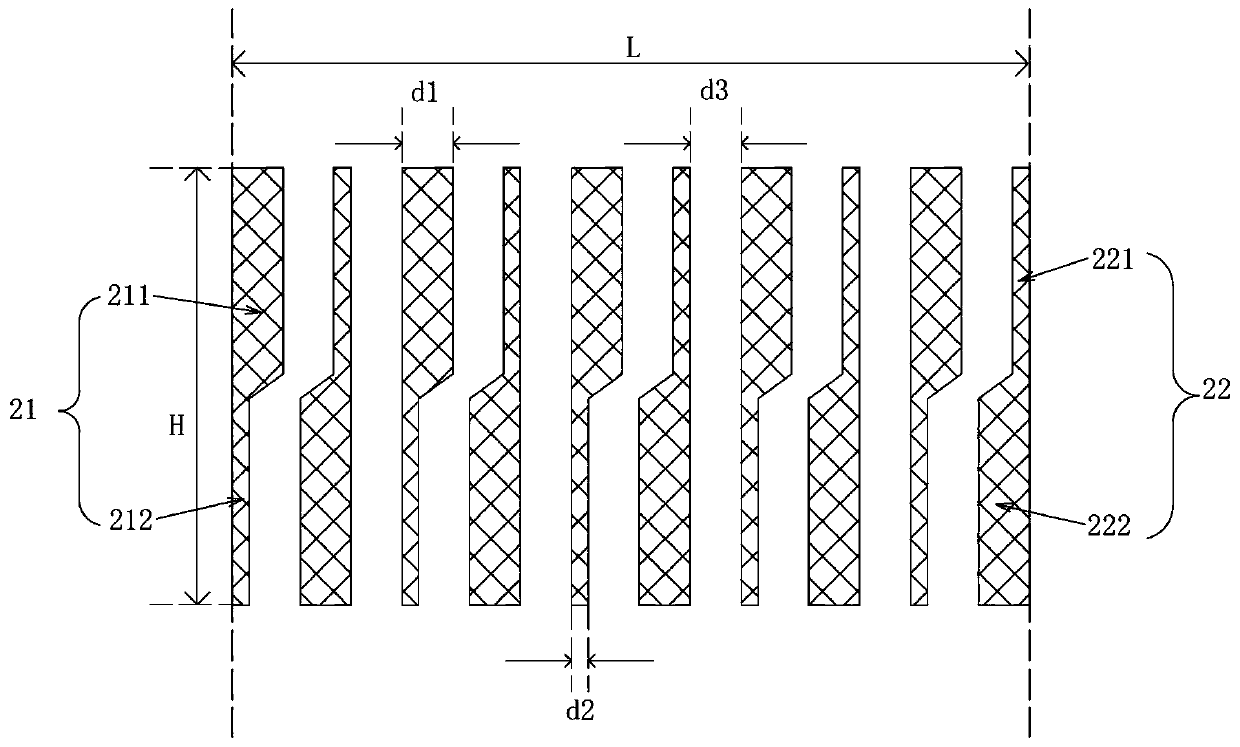

[0037] Embodiment two: as the description attached image 3 As shown, the first wide channel 211 and the second wide channel 222 are staggered, the first narrow channel 212 and the second narrow channel 221 are staggered, the line widths of the first wide channel 211 and the second wide channel 222 are equal, and the first wide channel 211 and the second wide channel 222 have the same line width. The line width of a narrow channel 212 and the second narrow channel 221 is equal, the first wide channel 211 and the second wide channel 222 are a single rectangle, the first narrow channel 212 and the second narrow channel 221 are strips, and the first narrow channel 212 The connection is set at the leftmost end of the first wide channel 211 and the connection is provided with a bevel transition, and the second narrow channel 221 is connected at the rightmost end of the second wide channel 222 and the connection is provided with a bevel transition. Similarly, according to the metal ...

Embodiment 3

[0038] Embodiment three: as the description attached Figure 4 As shown, the first wide channel 211 and the second wide channel 222 are staggered, the first narrow channel 212 and the second narrow channel 221 are staggered, the line widths of the first wide channel 211 and the second wide channel 222 are equal, and the first wide channel 211 and the second wide channel 222 have the same line width. The line width of a narrow channel 212 and the second narrow channel 221 is equal, the first wide channel 211 and the second wide channel 222 are a plurality of squares, the first narrow channel 212 and the second narrow channel 221 are strips, and the first narrow channel The 212 connection is set at the middle position of the first wide channel 211, and the second narrow channel 221 is connected at the middle position of the second wide channel 222. Similarly, based on the calculation of 10 metal lines, the line width d1 of the wide channel is set as 0.3mm, the line width d2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com