Concrete pouring process suitable for offshore building construction

A technology of concrete and buildings, which is applied in construction, infrastructure engineering, etc., can solve undisclosed problems, achieve the effects of reducing investment costs, wide application range, and controlling investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

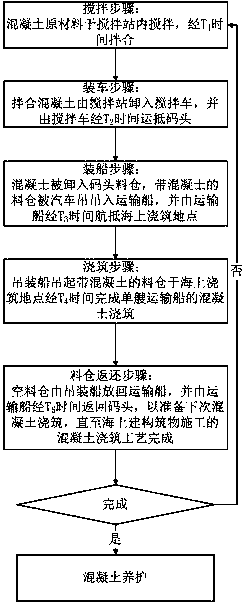

Method used

Image

Examples

Embodiment approach

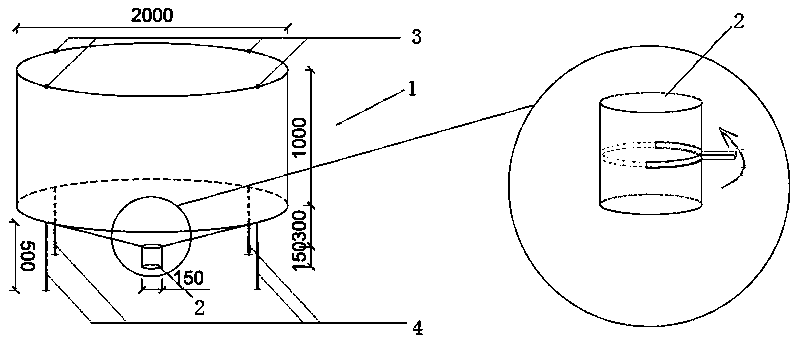

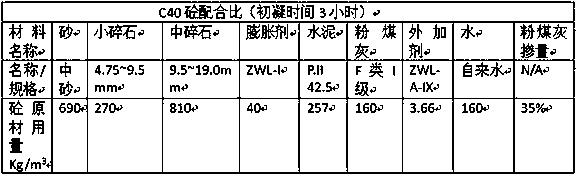

[0043] For the convenience of pouring, the silo is designed as a self-made conical silo. The volume of the silo is slightly larger than half of the volume of a single mixer truck, and the general volume is 3.5 cubic meters. It is convenient for vehicle dispatching, while avoiding concrete splashing during hoisting. And the loading of a single silo should not be more than 3 cubic meters, so as to ensure the safety control factor during hoisting. The height of the silo should be less than the height of the outlet of the concrete mixer truck, generally 1.5 meters high. Such as figure 2 , the bottom of the silo 1 has a cylindrical structure and a discharge port 2 that can be rotated and opened. In one embodiment, the feeding opening is opened by rotation relative to the silo; in another embodiment, the cylindrical structure includes an upper cylinder and a lower cylinder, and the lower cylinder is rotatable to open relative to the upper cylinder. In addition, the top of the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com