Production line for non-fried baked potato chips

A baked potato chips, non-fried technology, applied in the direction of baking, individual items, packaging, etc., can solve the problems of low production efficiency, weak connection continuity, affecting the taste of potato chips, etc., to improve production efficiency and quality and taste, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with drawings and embodiments.

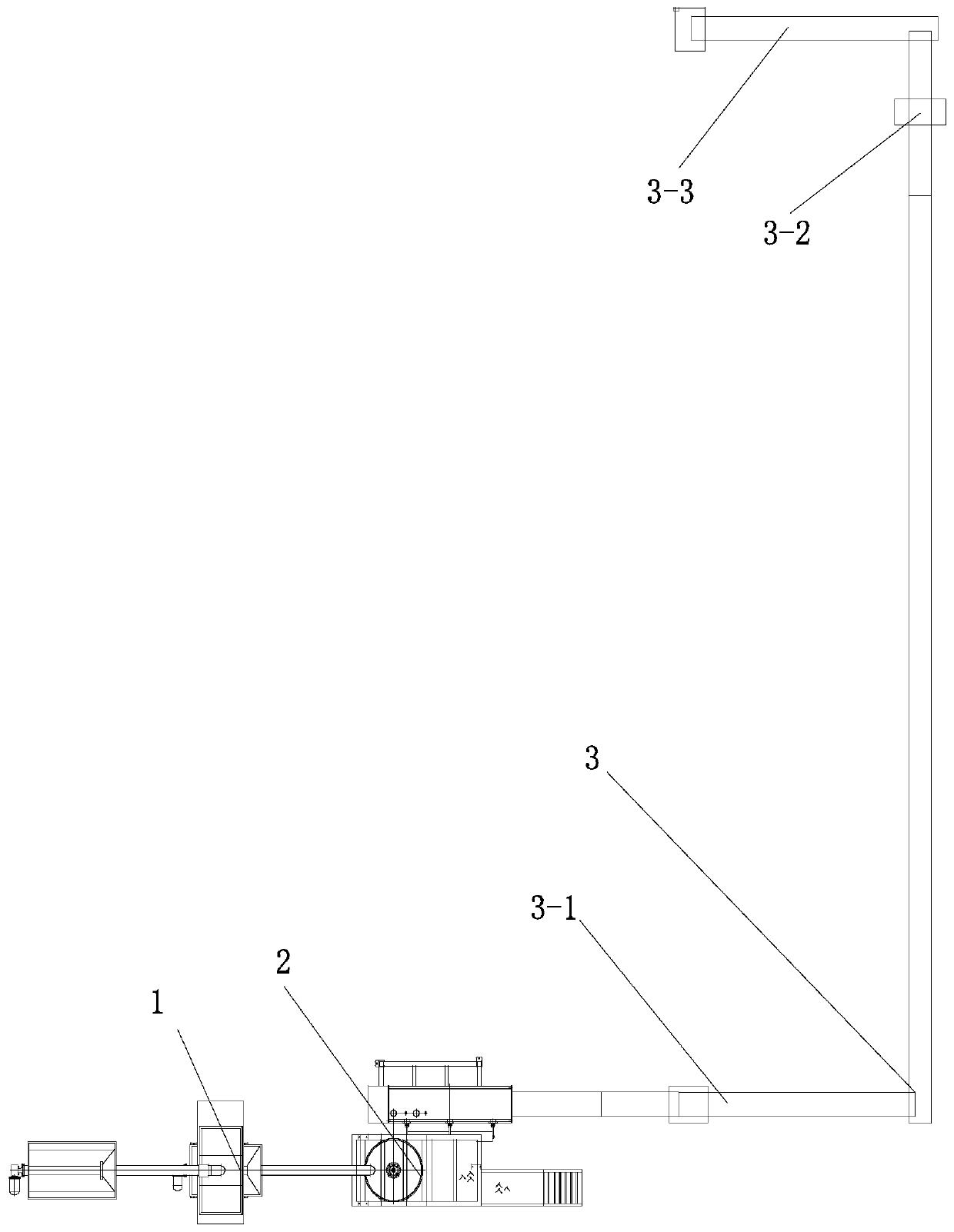

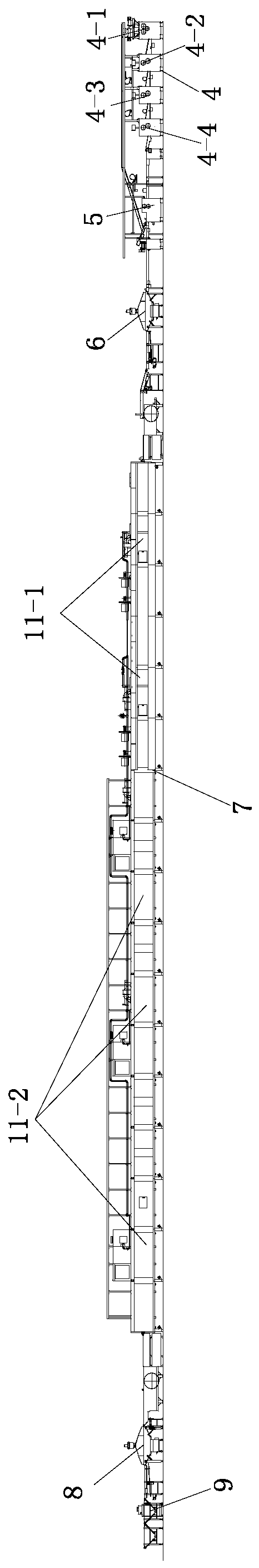

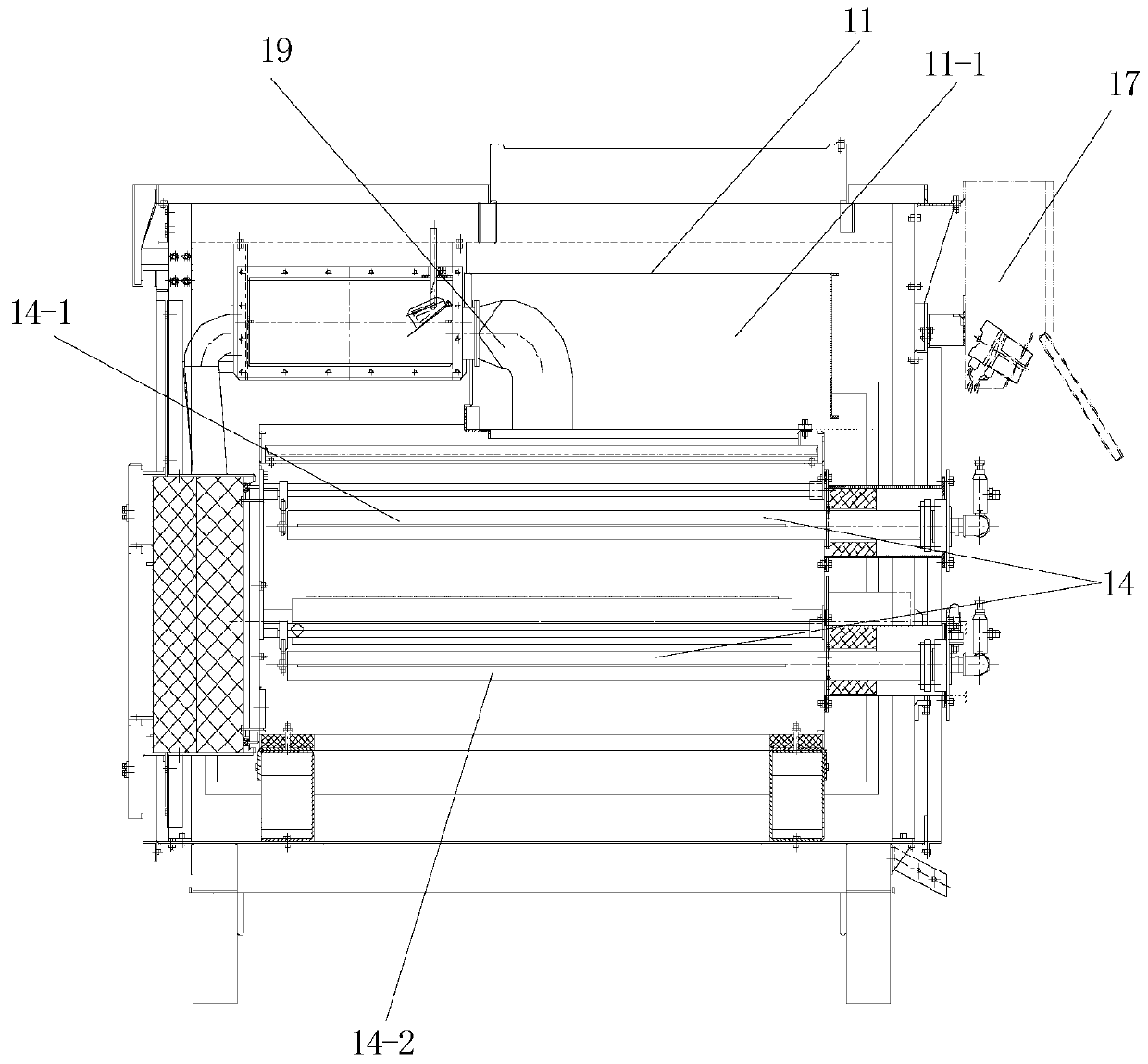

[0051] Such as Figure 1 to Figure 5 Production line for non-fried baked potato chips shown, including feeder, mixer, dough conveyor, roll mill, roll cutter, first oil injector, baking oven, second oil injector, spreader and palletizing equipment , the feeder, mixer, dough conveyor belt, rolling mill, roll cutting machine, first fuel injection machine, baking oven, second fuel injection machine, material spreading machine and supporting equipment are connected in sequence, and the baking oven includes Furnace body, upper air passage, lower air passage, combustion fire pipe, central combustion chamber, circulating fan and control box, the furnace body is provided with at least 2 direct fire zones and at least 3 indirect fire zones, and all direct fire zones are spliced together, All the indirect fire zones are spliced together and then spliced with the direct fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com