A kind of preparation method and application of sugar beet extract

A kind of sugar beet extract, technology of extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

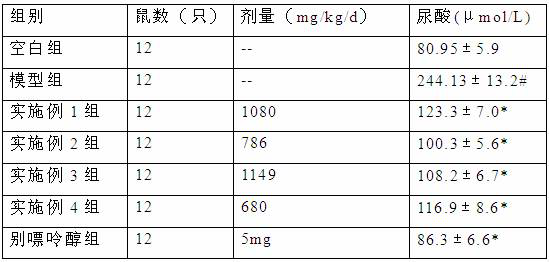

Image

Examples

Embodiment 1

[0031] A preparation method of sugar beet extract:

[0032] (1) Take 30kg of beets, break them into pieces as appropriate, add 180kg of 90% ethanol to extract 3 times, each time for 1 hour, to obtain the beet extract; add 600kg of water to the remaining beet pulp, decoct for 1 hour, and obtain the beet water extract, and Obtain water extract of beet at 3000 r·min -1 centrifuged at a rotating speed of 10 minutes to obtain the sugar beet water extraction centrifugate;

[0033] (2) Recover the ethanol from the beet extract to obtain the extract, combine the extract with the beet water extraction centrifuge, concentrate to a relative density of 1.05, add 95% ethanol with a weight fraction of 1 times, stir evenly, and precipitate at 20°C for 12 hours ;

[0034] (3) Take the alcohol precipitation supernatant, recover ethanol until there is no alcohol smell, add water with a weight fraction of 1 times, stir well, and let it stand for 3 hours;

[0035] (4) solid-liquid separation i...

Embodiment 2

[0039] A preparation method of sugar beet extract:

[0040] (1) Take 25kg of beet pulp (meal), crush it as appropriate, add 500kg of 30% ethanol to extract twice, 1 hour each time, to obtain the beet extract; add 250kg of water to extract the remaining beet pulp twice, 1 hour each time, To obtain the beet water extract, the beet water extract was heated at 10000 r min -1 Centrifuge at a rotating speed of 1 minute to obtain the sugar beet water extraction centrifugate;

[0041] (2) Recover the ethanol from the beet extract to obtain the extract, combine the extract with the beet water extraction centrifuge, concentrate to a relative density of 1.15, add 95% ethanol twice the weight fraction, stir evenly, and precipitate at 10°C for 24 hours ;

[0042] (3) Take the alcohol-precipitated supernatant, recover the ethanol until there is no alcohol smell, add water with a weight fraction 3 times, stir well, and let stand for 36 hours;

[0043] (4) Plate and frame filtration, the s...

Embodiment 3

[0047] A preparation method of sugar beet extract:

[0048] (1) Take 50kg of beets, crush them as appropriate, add 500kg of 60% ethanol to extract twice, each time for 1.5 hours, to obtain the beet extract; add 250kg of water to the beet pulp, decoct for 1 hour, to obtain the beet water extract, and the beet water Extraction at 20000 r·min -1 centrifuged at a rotating speed of 10 minutes to obtain the sugar beet water extraction centrifugate;

[0049] (2) Recover the ethanol from the beet extract to obtain the extract, combine the extract with the beet water extraction centrifuge, concentrate to a relative density of 1.30, add 95% ethanol with a weight fraction 5 times, stir evenly, and precipitate at 4°C for 48 hours ;

[0050] (3) Take the alcohol precipitation supernatant, recover ethanol until there is no alcohol smell, add water with a weight fraction of 5 times, stir well, and let stand for 48 hours;

[0051] (4) Plate and frame filtration, the solution is filtered th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com