Welding fume purifier

A purifier and welding fume technology, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of equipment performance degradation, shortened filter plate service life, harsh welding environment, etc., and achieve bearing capacity recovery, Guaranteed clean, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

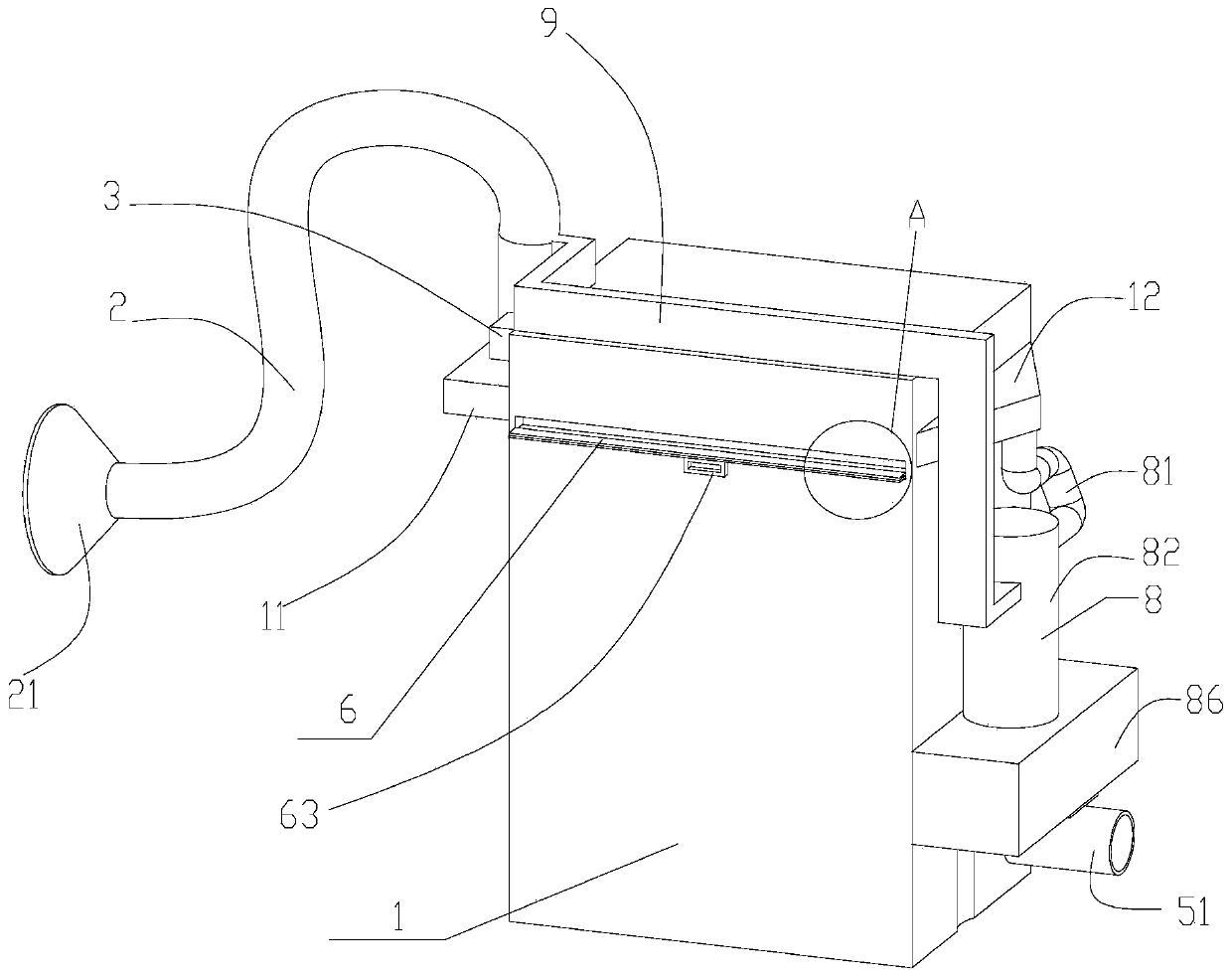

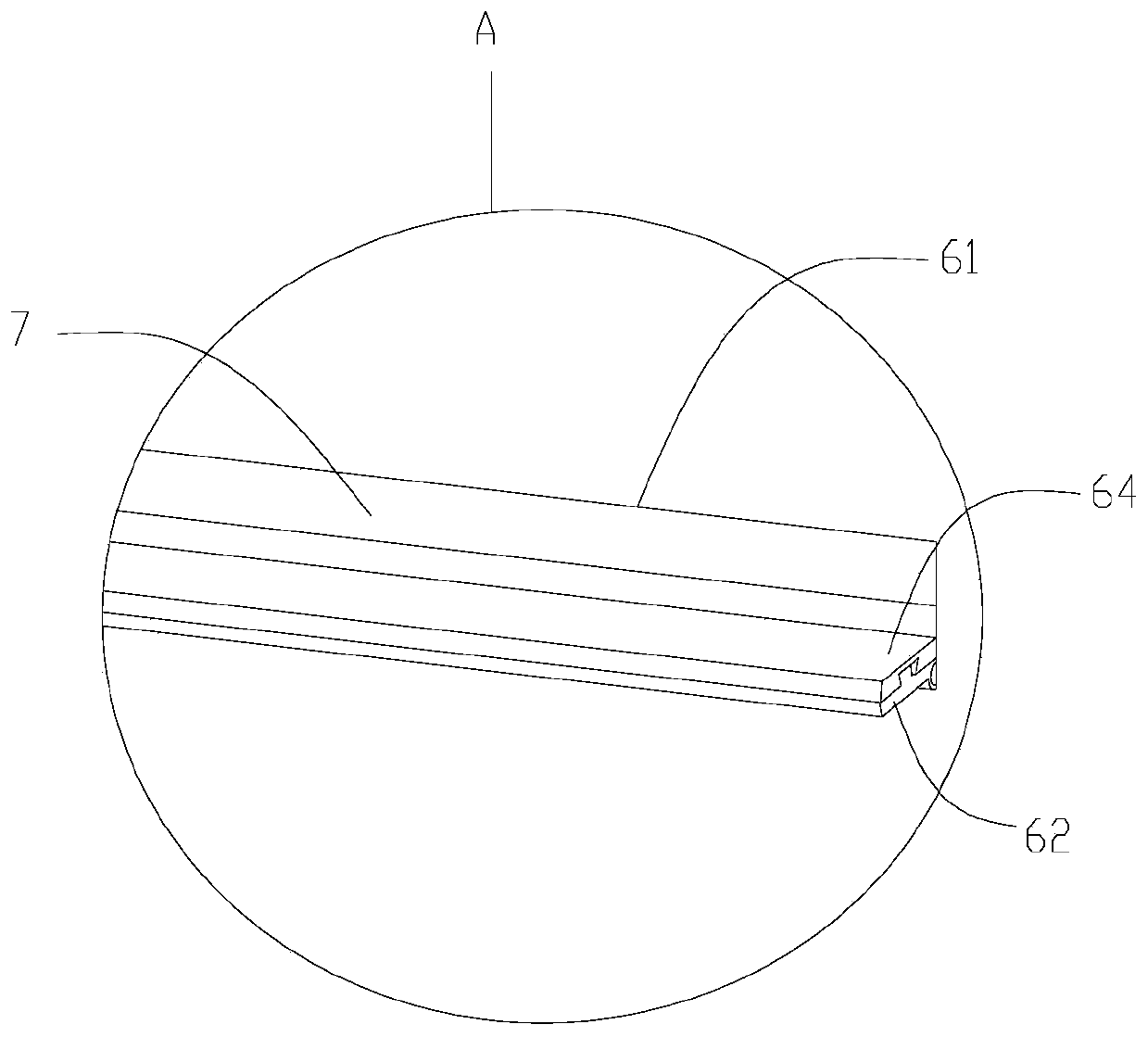

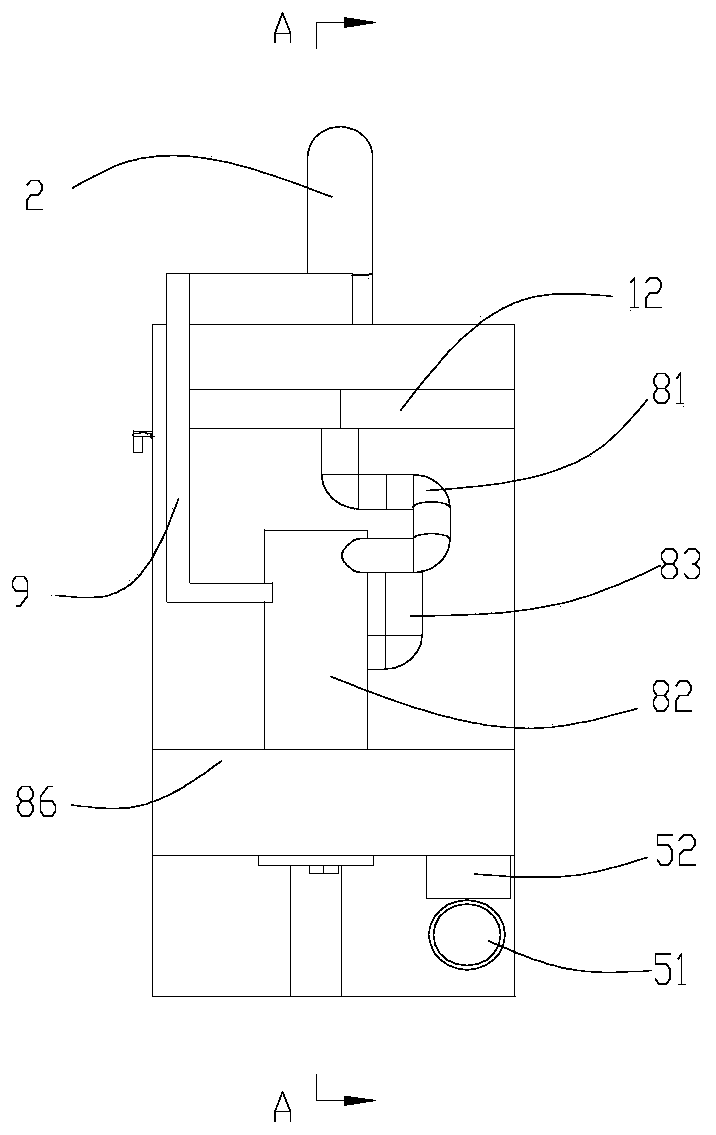

[0032] Such as figure 1 As shown, a welding fume purifier includes a first housing 1, an air inlet pipe 2, a first air pump 3, a first filter 41, a second filter 42, an air outlet 51, a second air pump 52, filter plate 7, quick release parts 6, particle filter assembly 8 and return air duct 9; the air inlet pipe 2 is a universal flexible suction arm available on the market, and the air inlet pipe 2 is connected to the first On the left side of the housing 1, the first air pump 3 is an air pump available on the market, the first air pump 3 is connected to the air intake pipe, and the air is sent into the first housing from the air intake pipe 1; the material of the first filter screen 41 is coated polyester fiber, which can remove dust, and is fixedly connected in the first housing 1, located below the filter plate 7, and the second filter screen 42 is The activated carbon filter screen available on the market is fixedly connected with the first housing 1 and is located below ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap