Automobile punching die ductile iron drawing model face cooling tool

A technology for stamping dies and automobiles. It is applied in the direction of casting molds, cores, and casting mold components. It can solve the problems of shrinkage and shrinkage, large changes in curved surfaces, and it is difficult to ensure surface shrinkage and shrinkage, so as to reduce shrinkage. Shrinkage cavity and accelerated cooling of molding sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

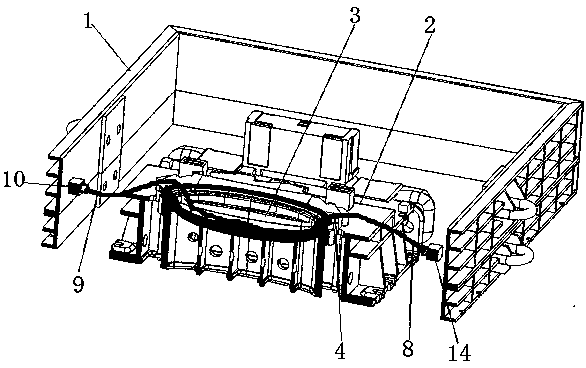

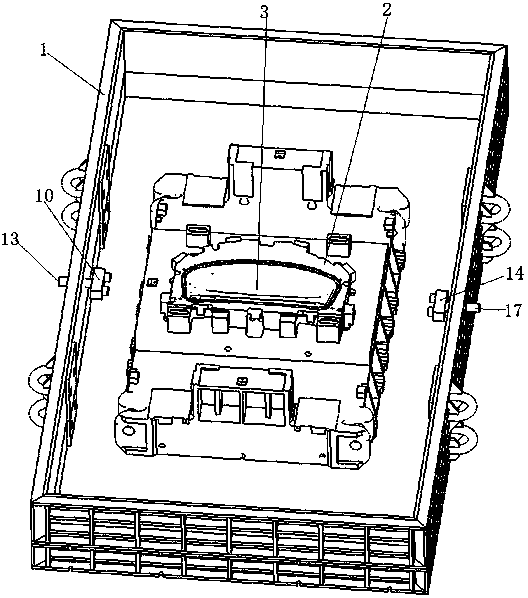

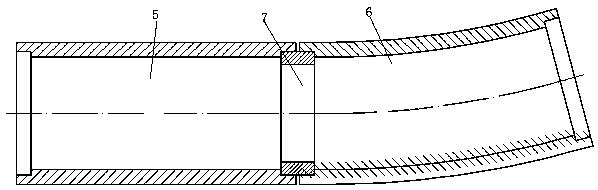

[0021] like Figure 1-5 As shown, the present embodiment provides a cooling tool for the ductile iron drawing model surface of an automobile stamping die, including a middle box 1, which is provided with a full-type casting mold 2 of an automobile stamping mold, and in the middle of the full-type casting mold 2 is The profile 3 of the automobile stamping die, the bottom of the profile 3 passes through the middle of the cooling pipe 4 transversely, and the cooling pipe 4 passes through the concave corner of the profile 3; the cooling pipe 4 is composed of a plurality of straight steel pipes 5 and bent steel pipes 6 The cooling pipe 4 formed by combining a plurality of straight steel pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com