Hole site correction method applied to automatic drilling and riveting of curved surface products

A technology of automatic drilling and riveting and curved surface, which can be used in ground installations, program-controlled manipulators, manipulators, etc., and can solve problems such as hole position errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0073] A hole position correction method applied to automatic drilling and riveting of curved surface products according to the present invention comprises the following steps:

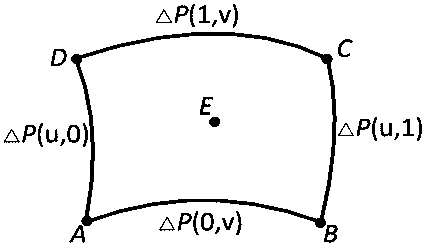

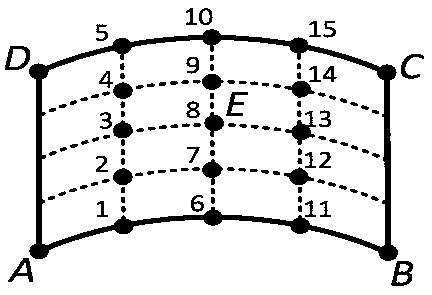

[0074] S1: Set a number of holes to be processed in the hole-making area, and set four reference holes at the four corners of the hole-making area. The theoretical position, normal direction and actual position of the reference holes are known. First, the theoretical positions and Comparing the actual positions to obtain the vector errors of the four reference holes, combining the vector error and the normal fitting bilinear mixed Coons error surface, constructing the error surface function △P(u,v), the information of the four reference holes cannot be obtained during fitting Determine the modulus length of the tangent vector and set it as an unknown number;

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com