Intelligent bag drawing detection machine

A detection machine and bagging technology, which is applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of inability to determine the validity of measurement results, potential safety hazards, and high labor intensity of staff, so as to improve sampling efficiency and reduce labor. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

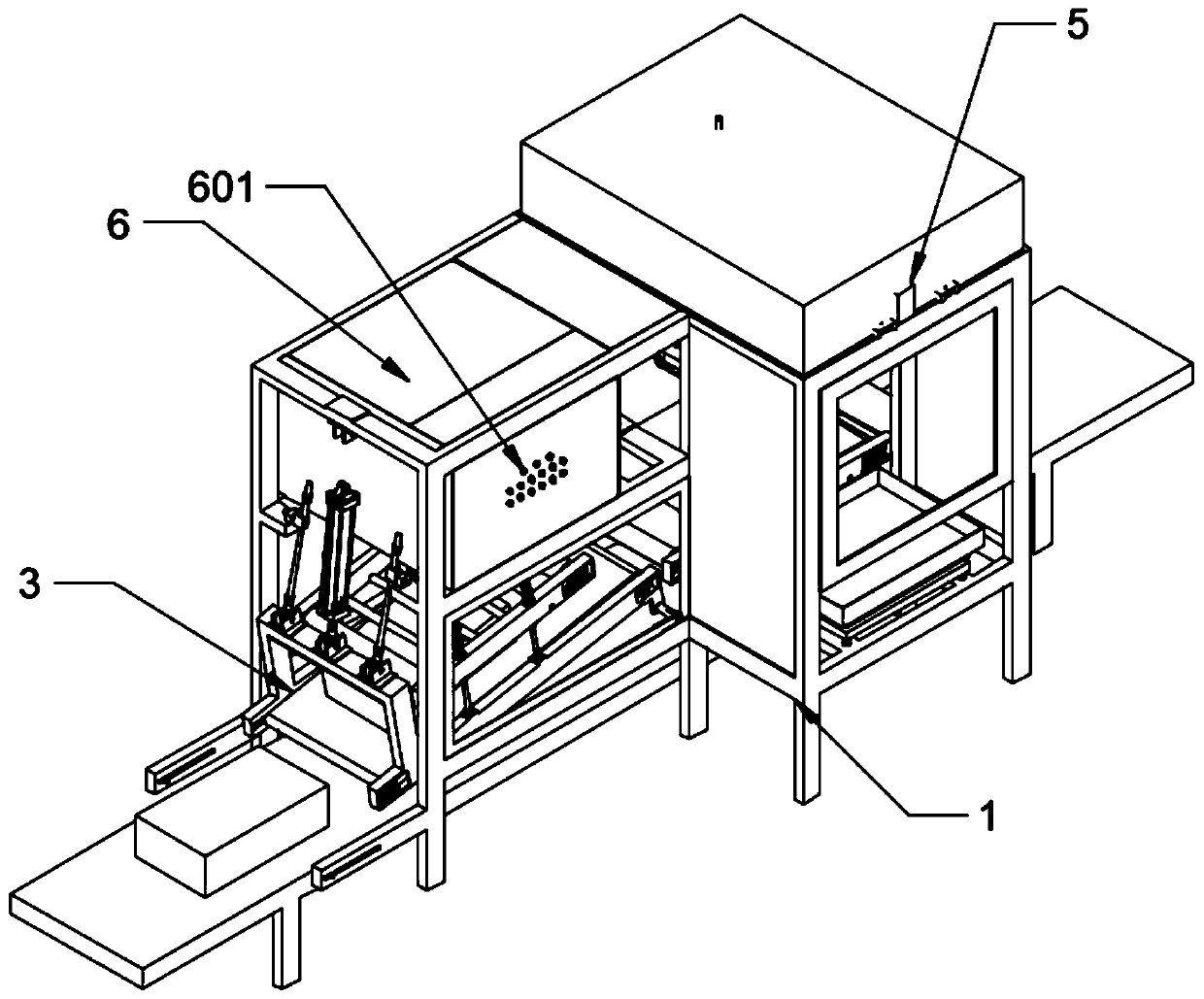

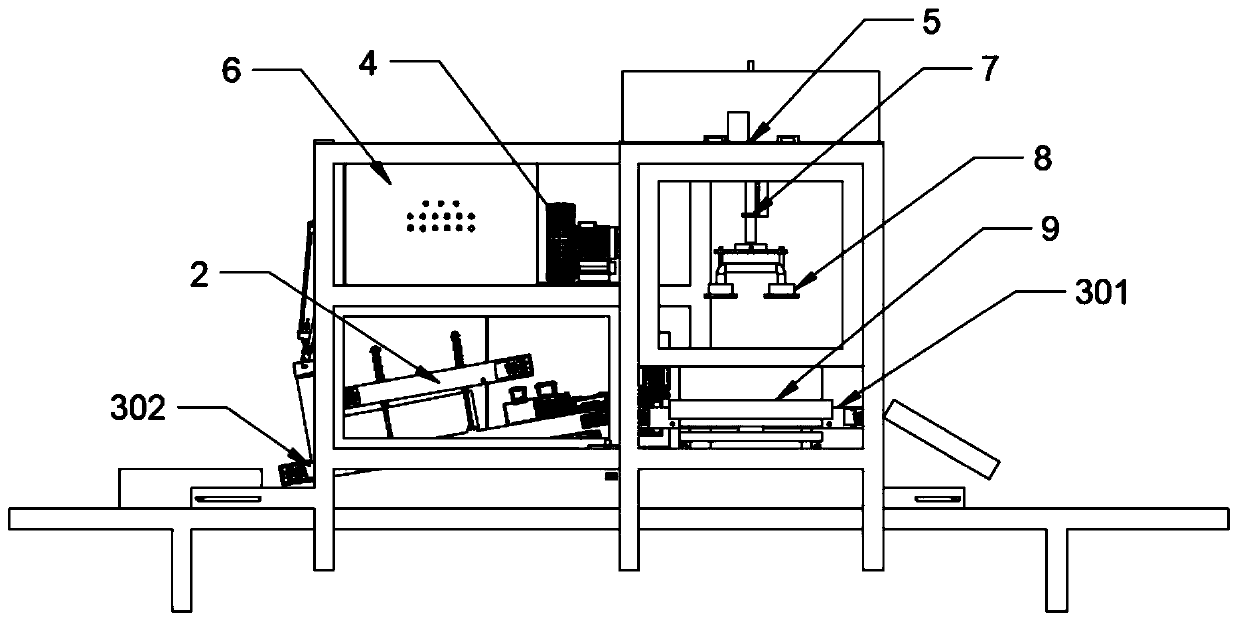

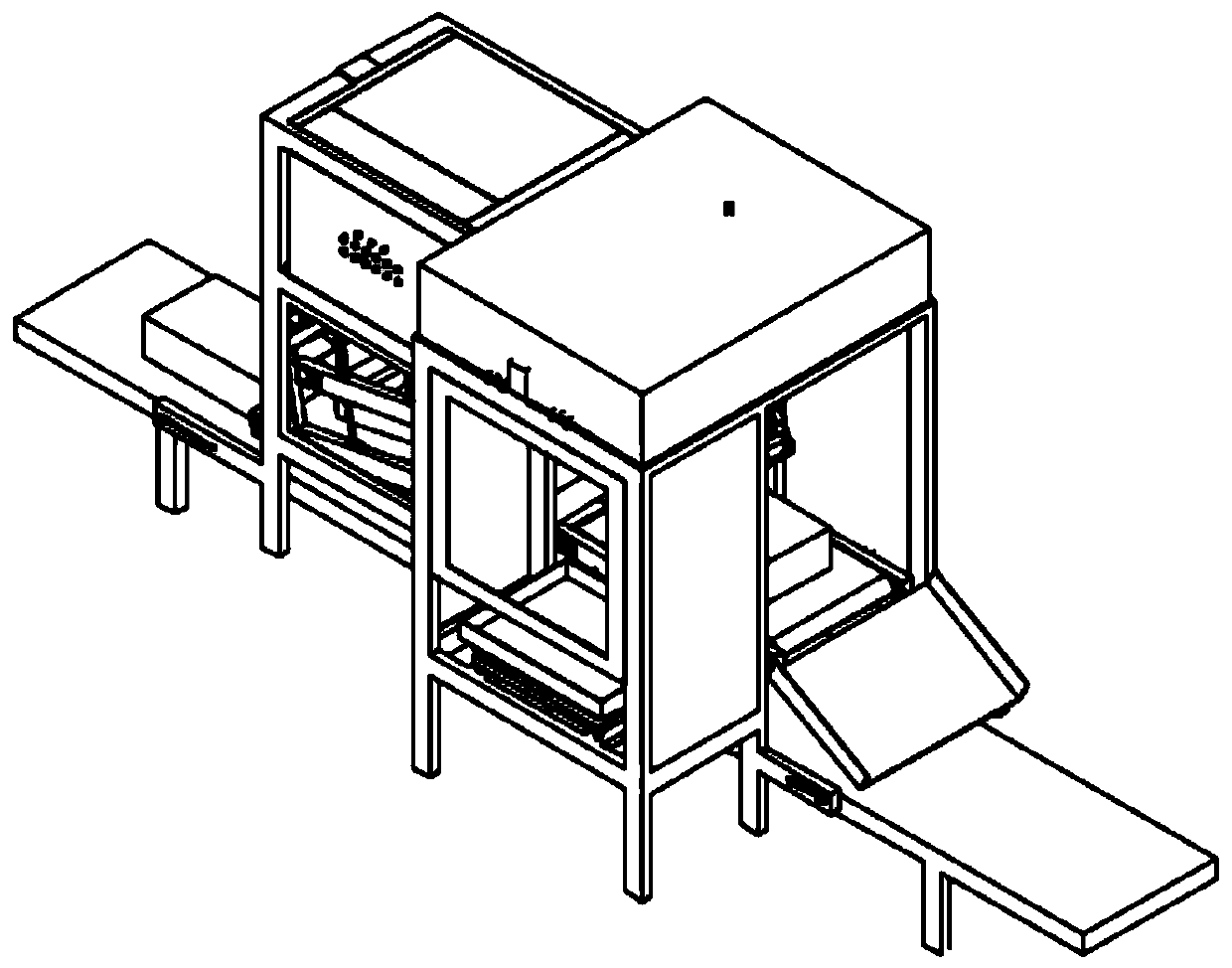

[0024] see Figure 1-4 , an intelligent bag detection machine, including a mounting frame 1, an electric control system 6 and a bag blocking device 2 electrically connected to the electric control system 6, a conveying structure 3, and a material retrieving system 5 are arranged on the mounting frame 1 , the electric control system 6 and the weighing device 9, the conveying structure 3 is fixedly installed on the mounting frame 1, the package blocking device 2 is located above the conveying structure 3 and exhausts the package on the conveying structure 3, the weighing device 9 Located on the side of the conveying mechanism 3 , the reclaiming system 5 is movably installed on the mounting frame 1 above the conveying structure 3 and the weighing device 9 .

[0025] Further, the specific type of the conveying structure 3 is not limited. In this embodiment, preferably, the conveying mechanism 3 includes a linear track structure 301 and an inclined track structure 302 , and the pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com