Automatic feeding device for annealing processing of cylindrical parts of electronic products

An electronic product and automatic feeding technology, which is applied in the direction of conveyor objects, object destacking, transportation and packaging, etc., can solve the problems of intermittent feeding, affecting the effect of annealing processing, low work efficiency, etc., and achieves a simple structure , Avoid mechanical damage, high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

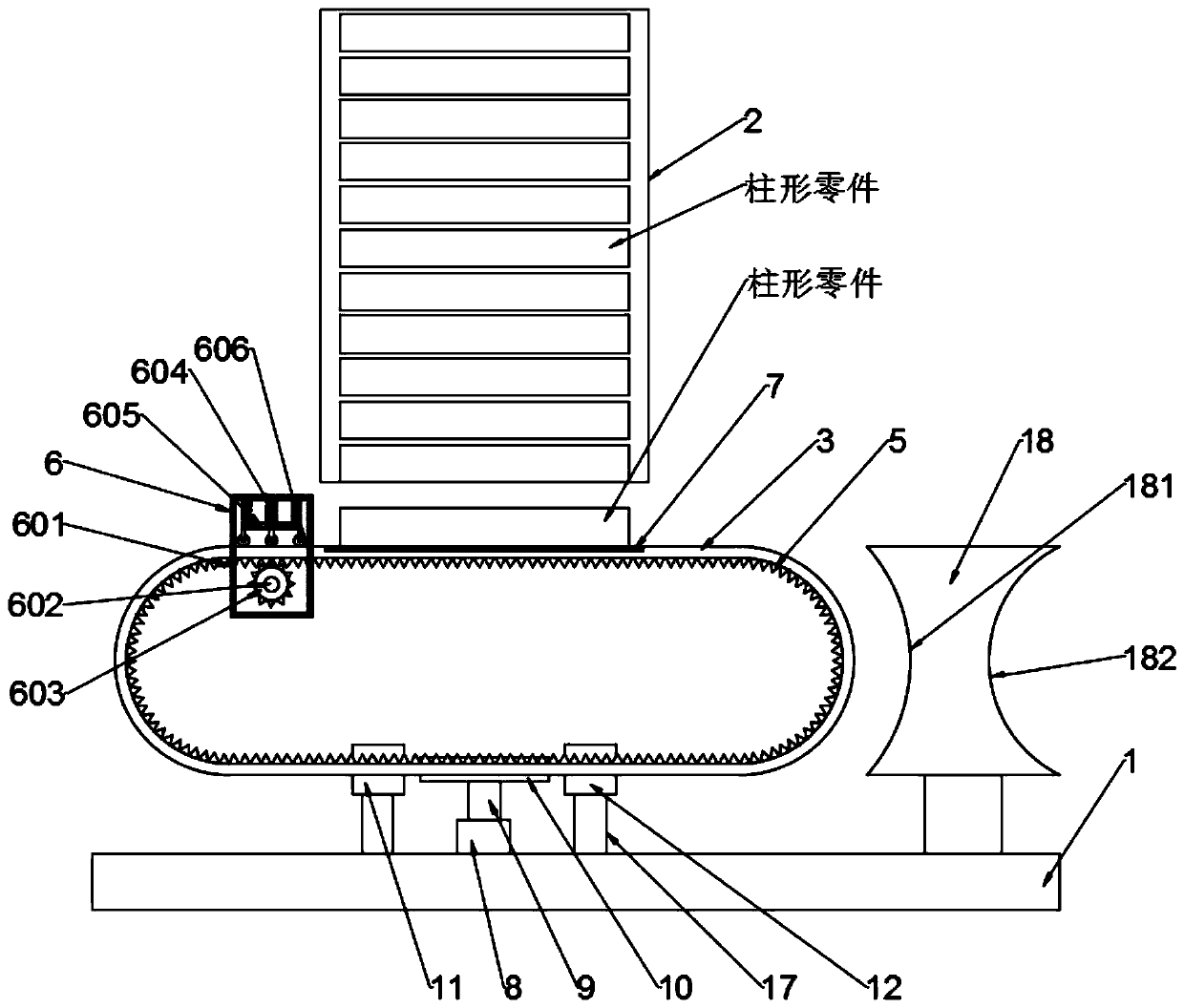

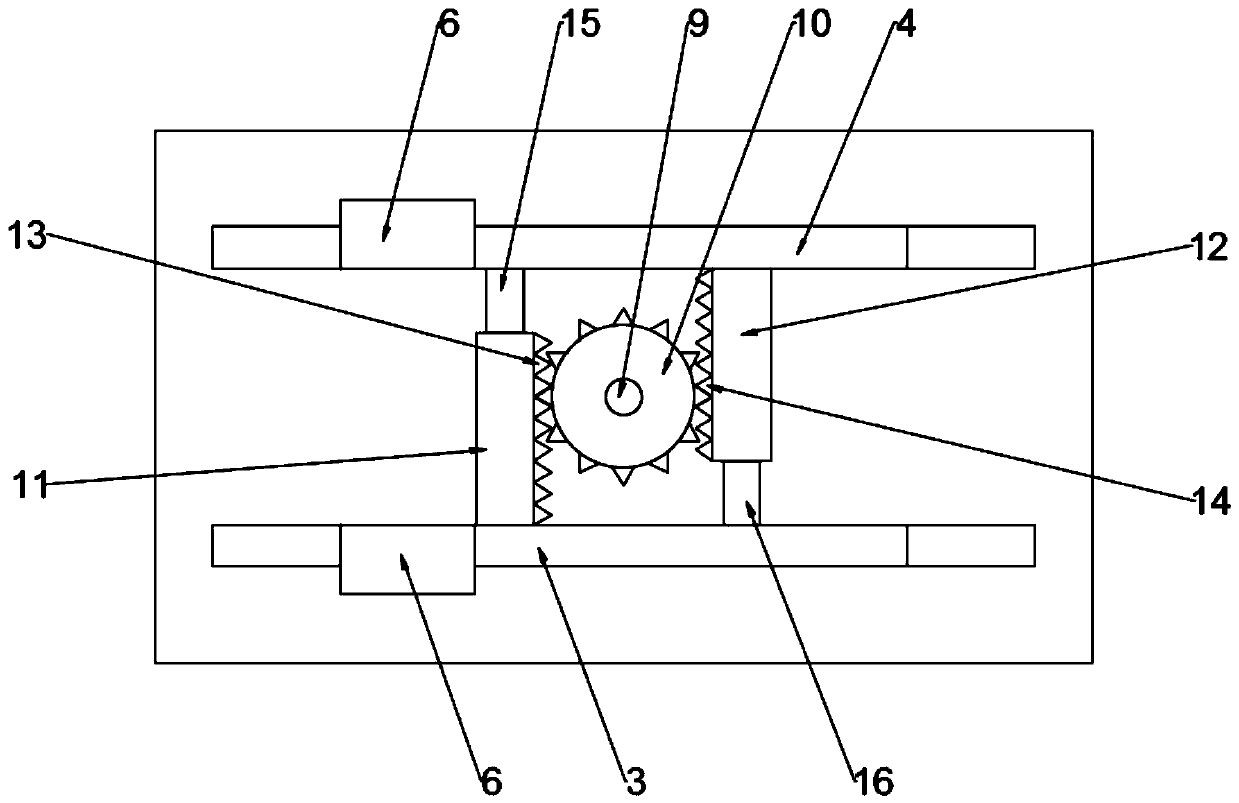

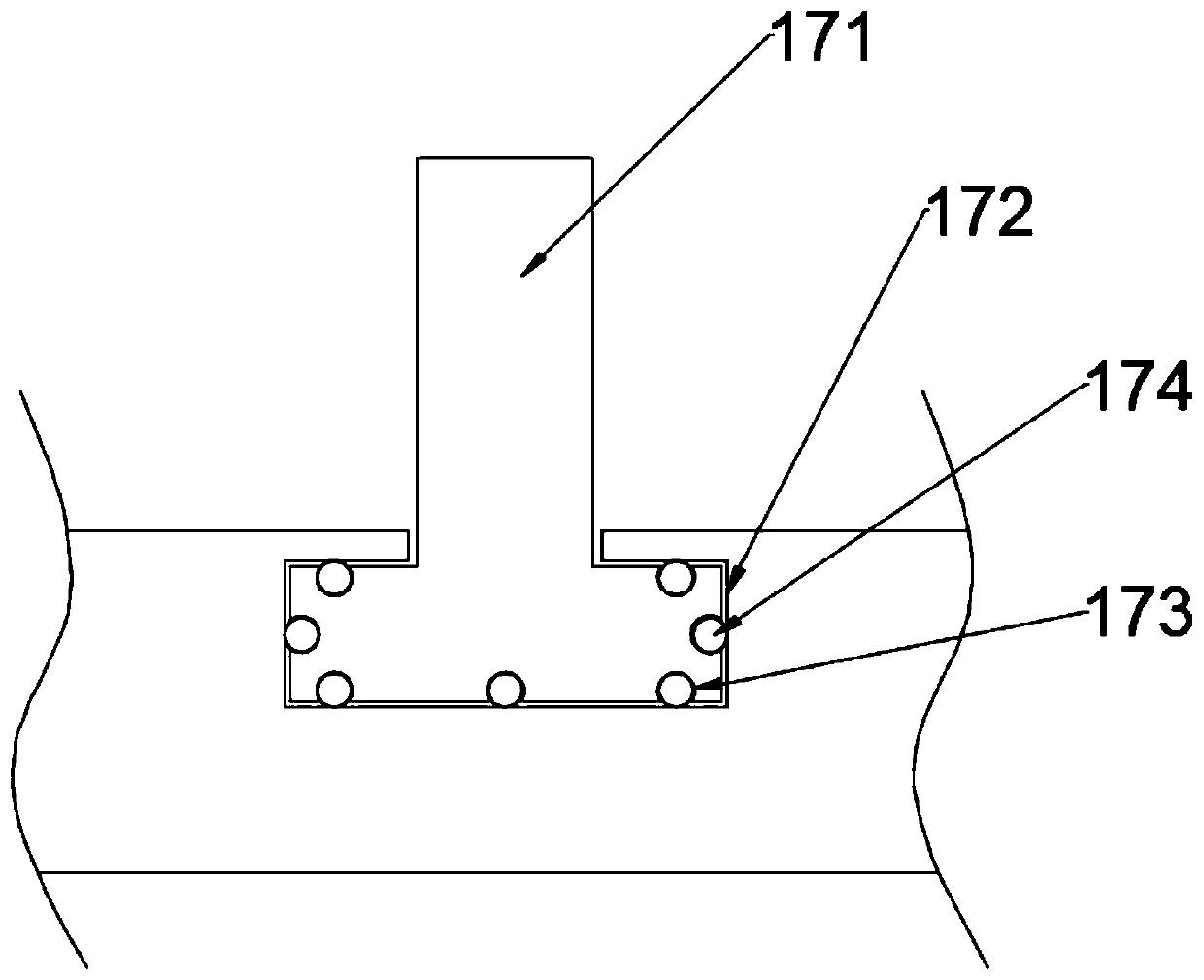

[0036] see figure 1 , an automatic feeding device for the annealing processing of cylindrical parts of electronic products, comprising a base 1, a storage device 2 is arranged on the upper side of the base 1, a plurality of horizontally arranged cylindrical parts are placed in the storage device 2, the base 1 and A first waist-shaped frame 3 and a second waist-shaped frame 4 arranged along the length direction of the cylindrical parts are arranged between the storage devices 2, the first waist-shaped frame 3 and the second waist-shaped frame 4 are arranged in parallel front and back, the first waist-shaped frame The waist-shaped frame 3 and the second waist-shaped frame 4 are symmetrically arranged compared with the base 1, and the waist-shaped rack 5 is fixed on the inner wall of the first waist-shaped frame 3 and the second waist-shaped frame 4, and the first waist-shaped frame 3 and the The second girdle frame 4 is all slidingly clamped with a sliding pusher 6 that slides a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com