A kind of asphalt concrete production and processing equipment

A technology for asphalt concrete and processing equipment, which is applied in roads, constructions, road repairs, etc. It can solve the problems of not being able to screen crushed stone materials, affecting the processing and use of finished materials, and being easily mixed with large pieces of crushed stone, so as to improve the filtration efficiency. Low, reduce heat loss, ensure the effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

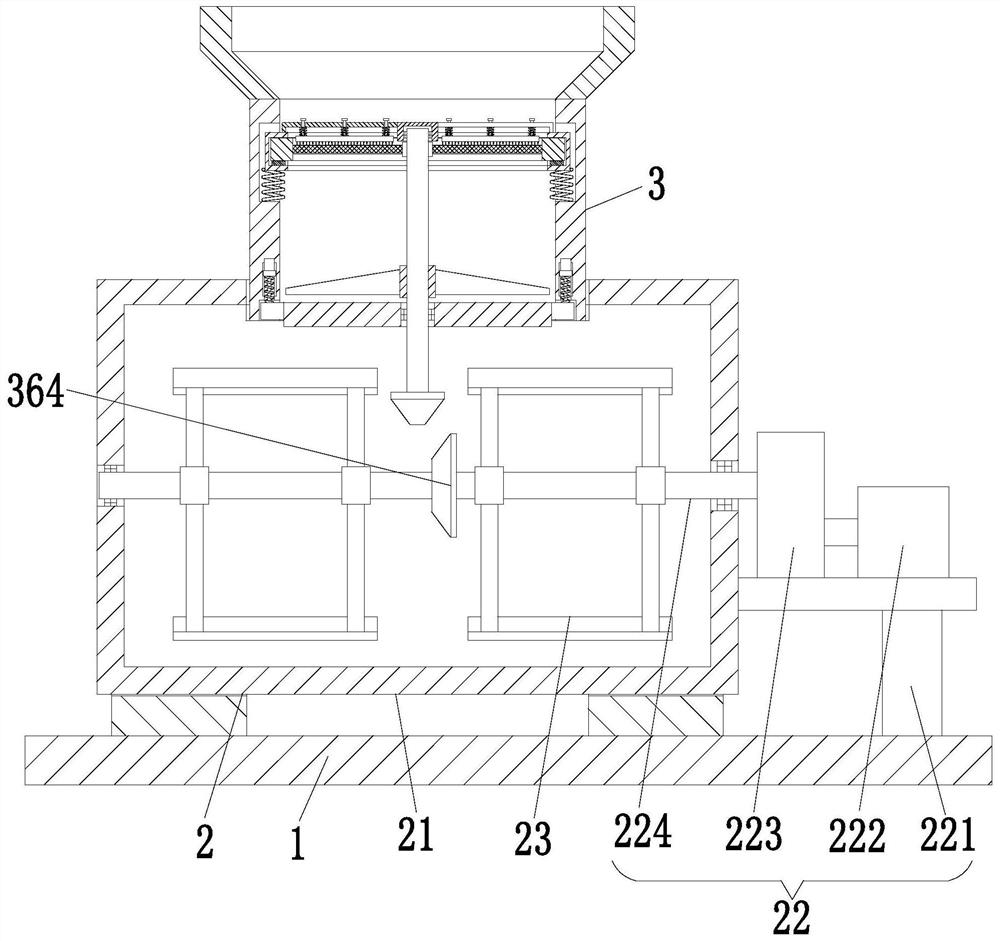

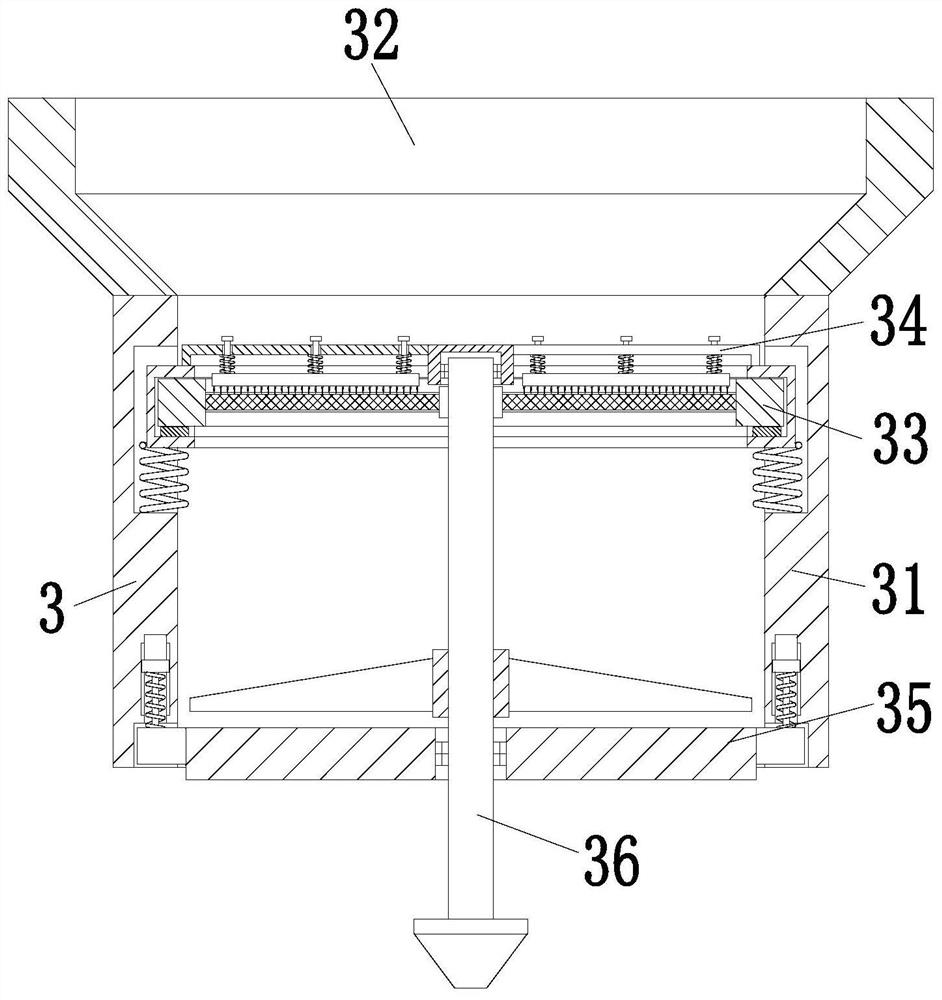

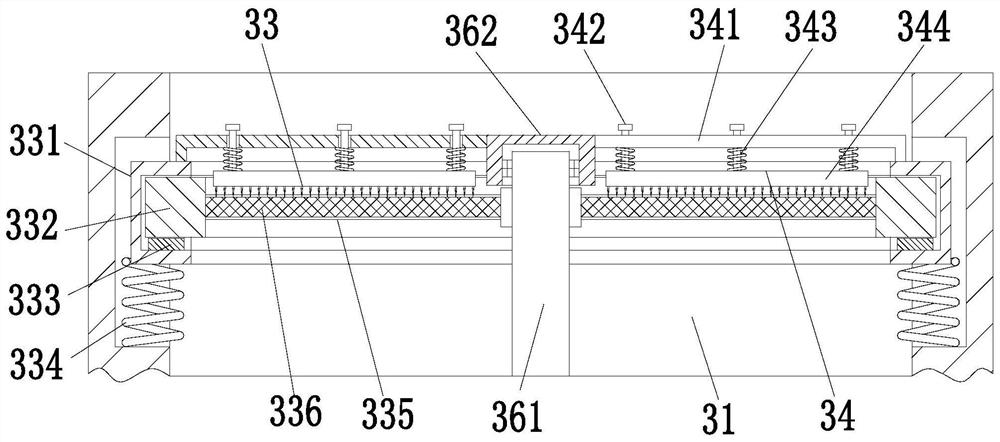

[0027] Such as Figure 1 to Figure 5 As shown, a kind of asphalt concrete production and processing equipment includes a base plate 1, a stirring device 2 and a feeding device 3. The base plate 1 is uniformly provided with installation holes, and the middle part of the upper end of the base plate 1 is equipped with a stirring device 2. The upper end of the stirring device 2 A through groove is provided, and a feeding device 3 is installed in the through groove.

[0028] The stirring device 2 includes a stirring tank 21, a driving mechanism 22 and a stirring frame 23, the stirring tank 21 is a cylindrical hollow structure, the right side of the stirring tank 21 is provided with a driving mechanism 22, and the lower end of the driving mechanism 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com