Building thermal insulation wall

A building insulation and wall technology, applied in the direction of insulation, construction, building components, etc., can solve the problems of increased risk, damage, corrosion and damage of foam insulation layer, etc., to prevent the entry of dust and water vapor, increase service life, increase The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

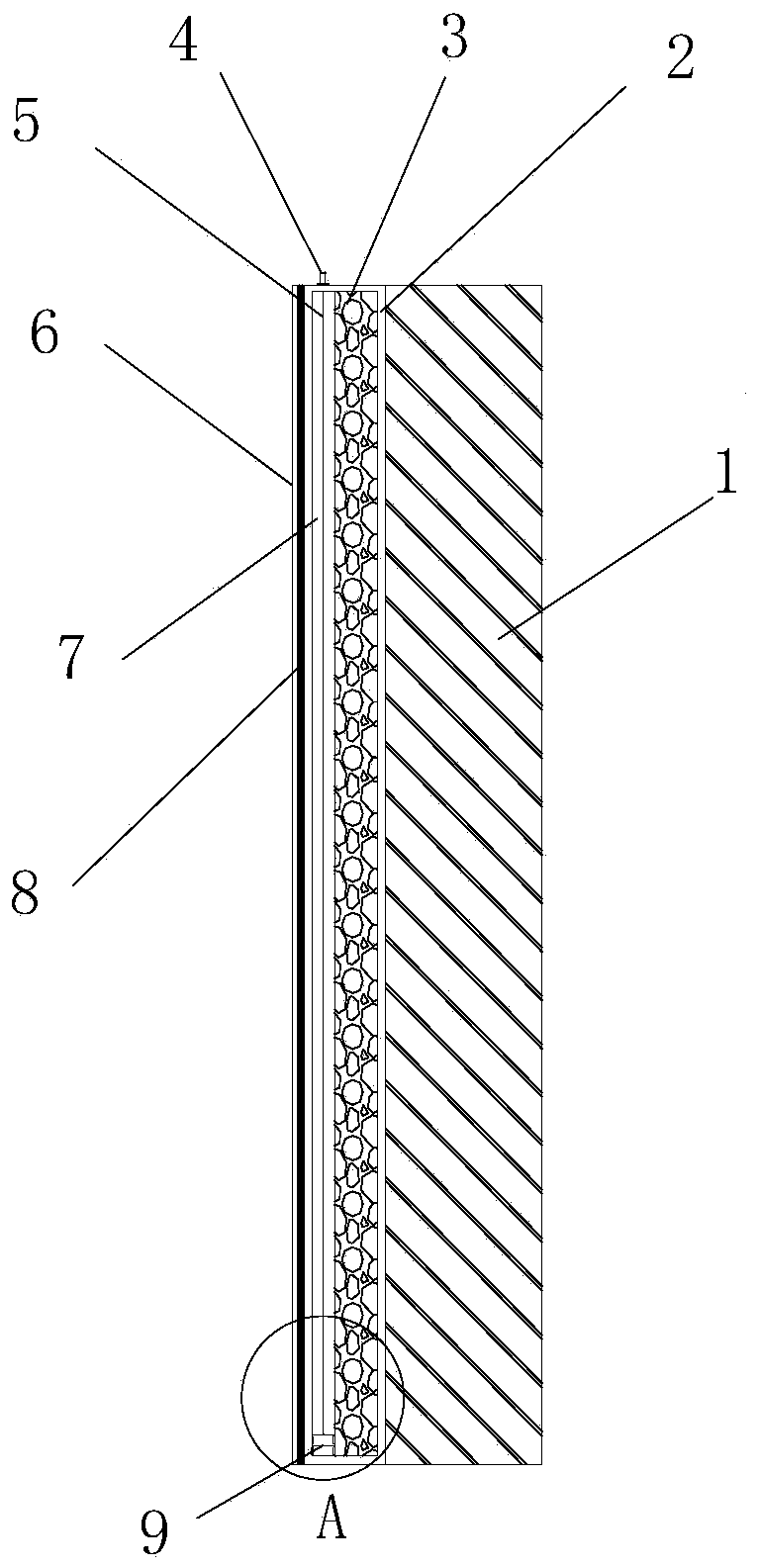

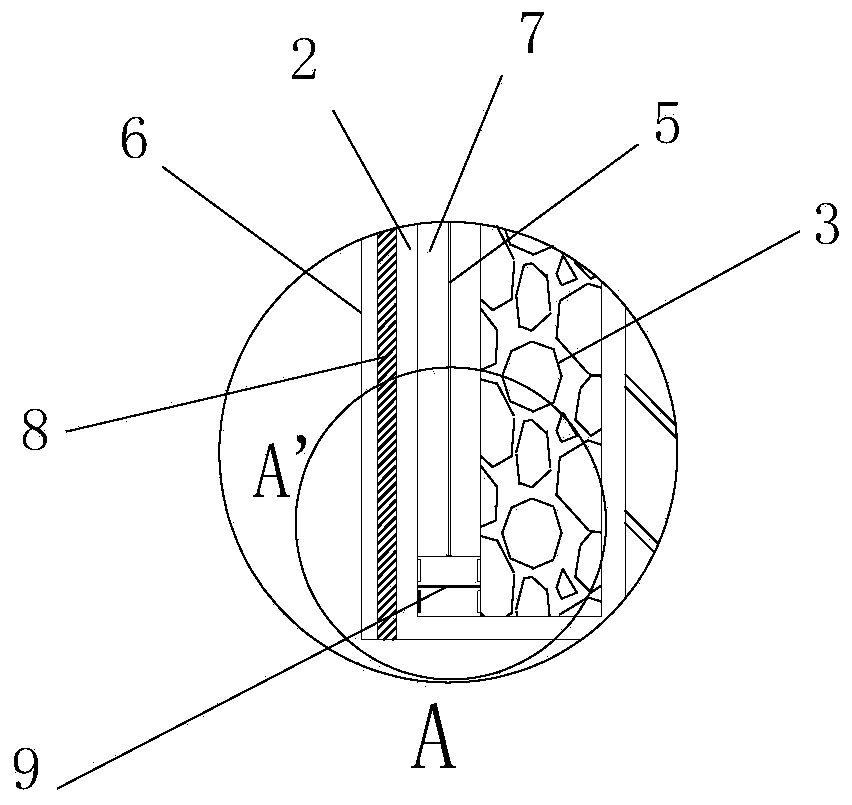

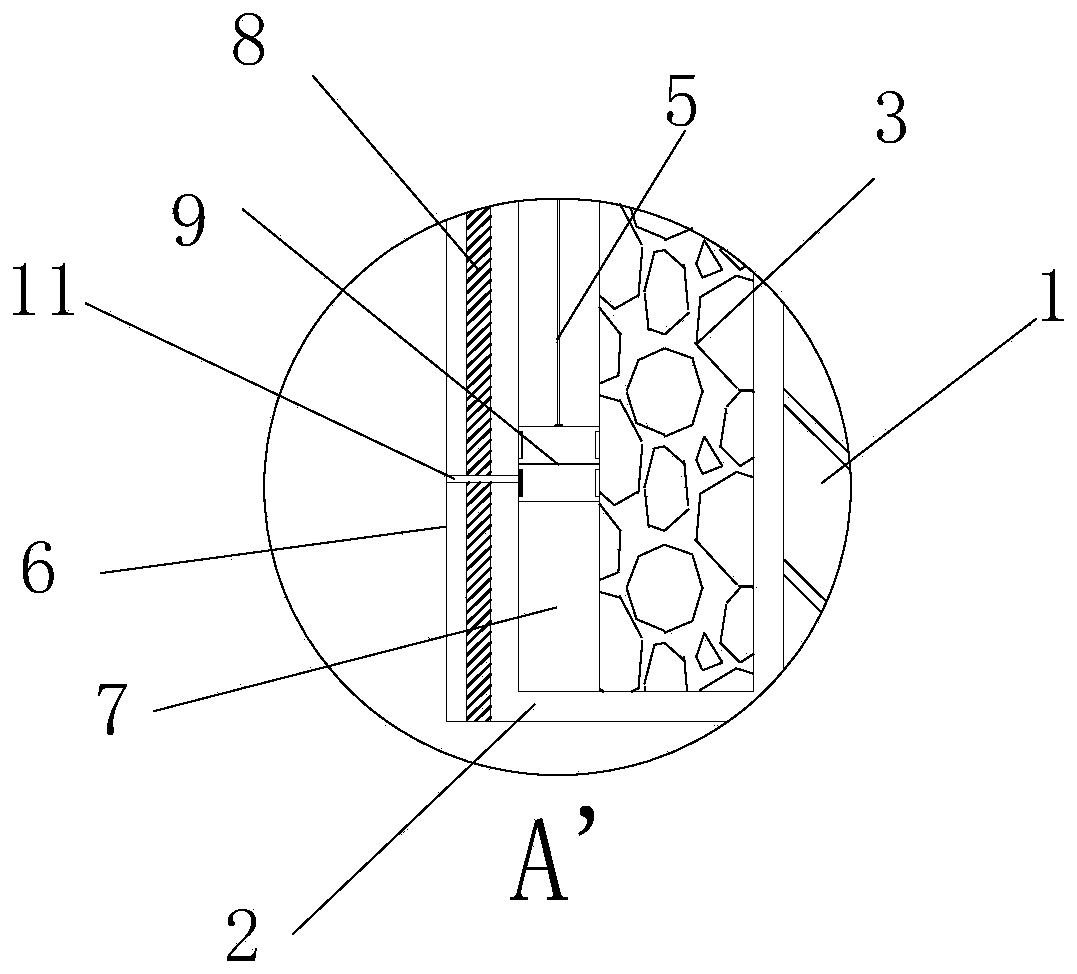

[0019] Such as figure 1 and figure 2 As shown, the thermal insulation wall of this building includes a building concrete matrix 1, and an insulating layer is installed on the outer side of the building concrete matrix 1, and the outer side of the insulating layer is bonded and fixed with a layer of decorative layer 6 through a thin concrete layer 8;

[0020] In this embodiment, the thermal insulation layer includes a thermal insulation shell 2, and a sealed installation cavity is provided inside the thermal insulation shell 2, and a layer of thermal insulation sponge layer 3 is filled in the installation cavity close to the building concrete base 1, and the installation cavity is completed. An air storage chamber 7 is formed behind the heat preservation sponge layer 3, and the air storage chamber 7 is arranged on one side close to the decorative layer 6, and an air charging port 4 is arranged on the top of the heat preservation outer shell 2, and the air storage chamber 7 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap