Electro-hydraulic multi-speed cushion valve capable of being used for near-water medium

A buffer valve, medium technology, applied in the direction of servo motors, servo motor components, fluid pressure actuation system components, etc., can solve the impact of the service life of hydraulic pipeline components, cannot change the flow rate of the hydraulic system circuit, and the valve cannot adjust the flow rate. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

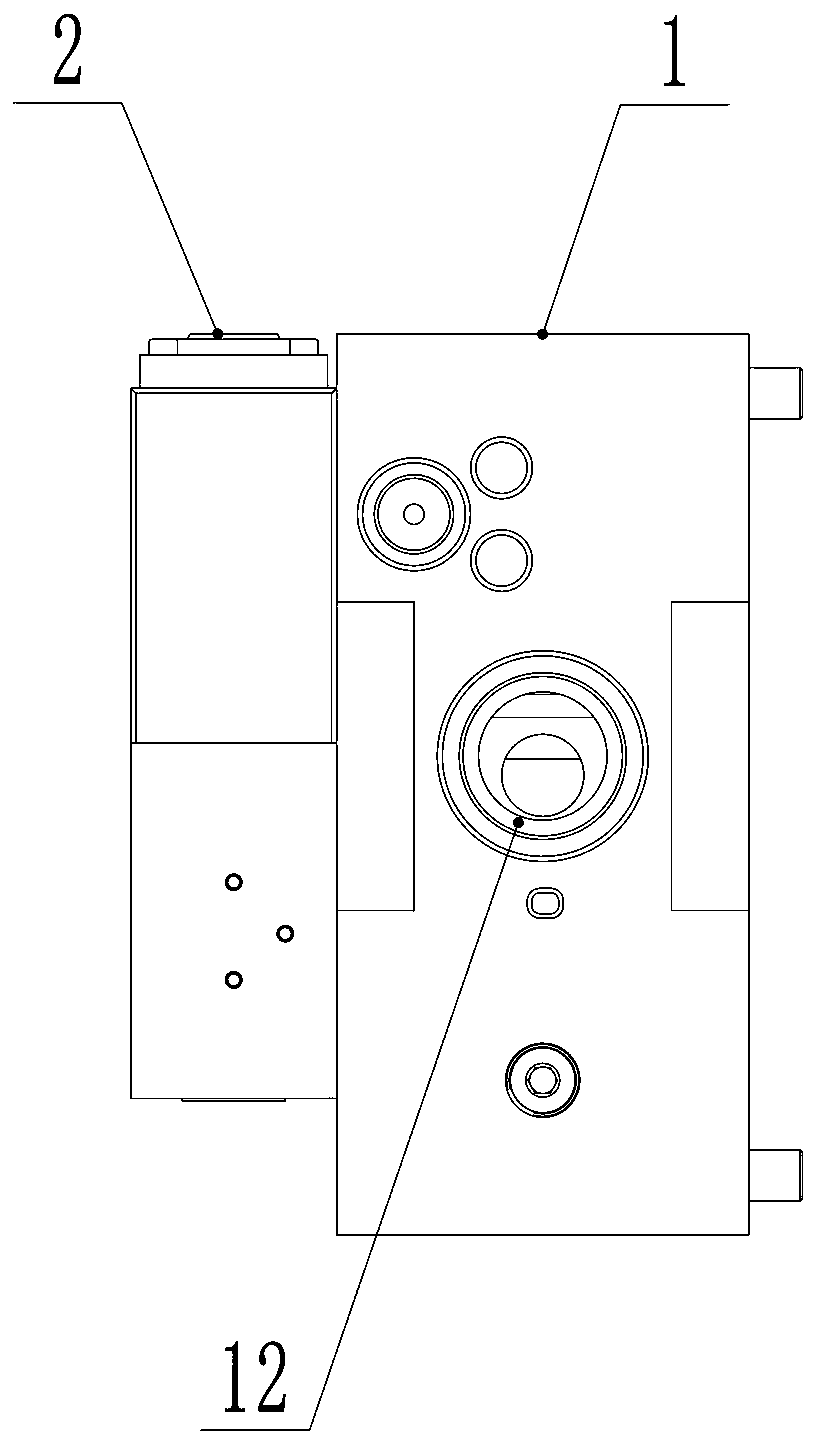

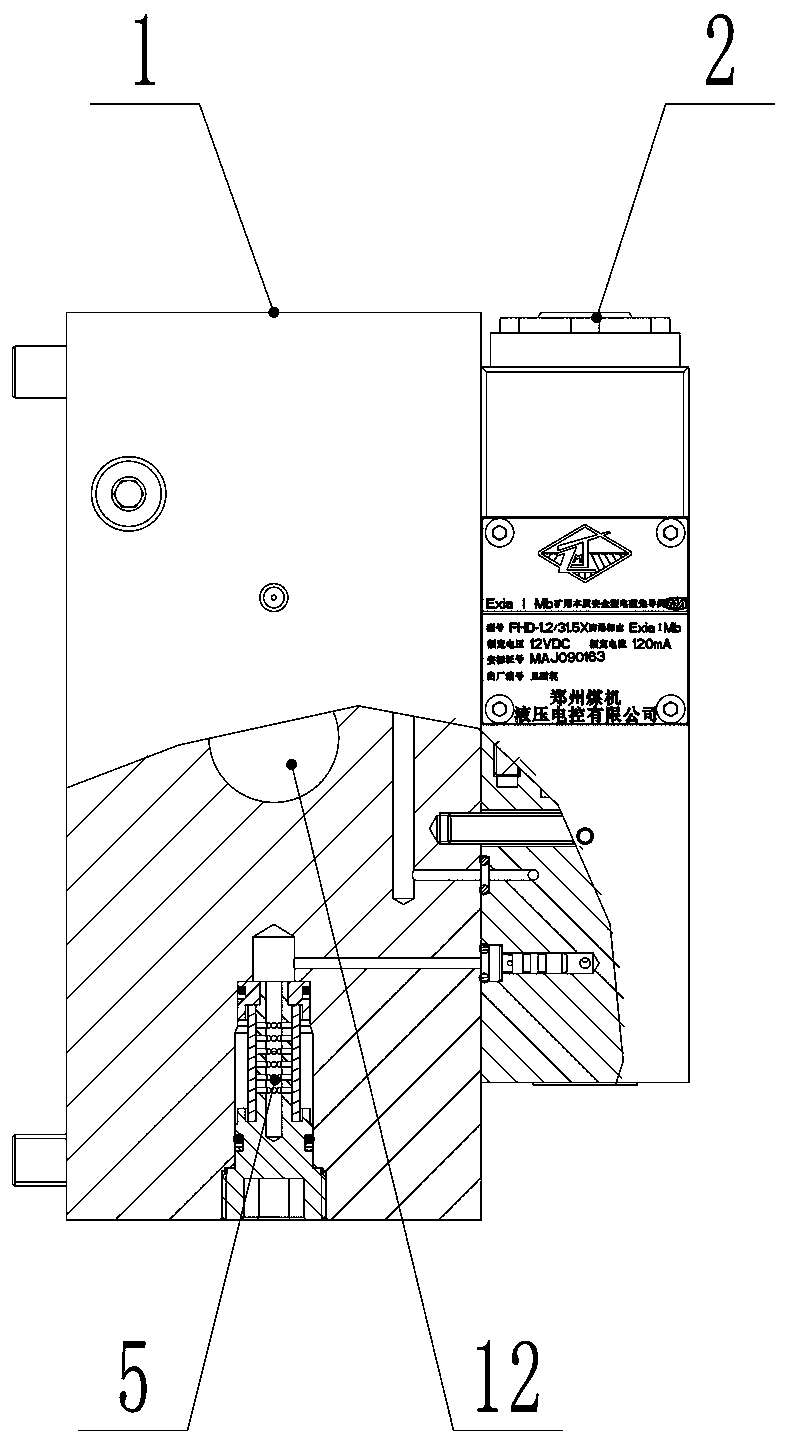

[0024] Such as Figure 1-5 As shown, an electro-hydraulic multi-speed buffer valve that can be used for near-water media includes a main valve body 1, a main channel opened in the main valve body 1, and a main valve body opened in the main valve body 1. The thin flow channel 4 and the electromagnetic pilot valve 3, the main channel includes a liquid inlet flow channel 11, a liquid outlet flow channel 12, and a communication cavity 13 connected between the liquid inlet flow channel 11 and the liquid outlet flow channel 12 , the communication chamber 13 is provided with a shut-off valve assembly, the shut-off valve assembly is a hydraulically controlled one-way valve string 3; The liquid outlet channel 12; the liquid inlet channel 11 is also connected with the control oil inlet of the electromagnetic pilot valve 2, and the first control oil outlet of the electromagnetic pilot valve 2 (ie Figure 4 Port B in the center) is connected to the hydraulic control port of the hydraulic...

Embodiment 2

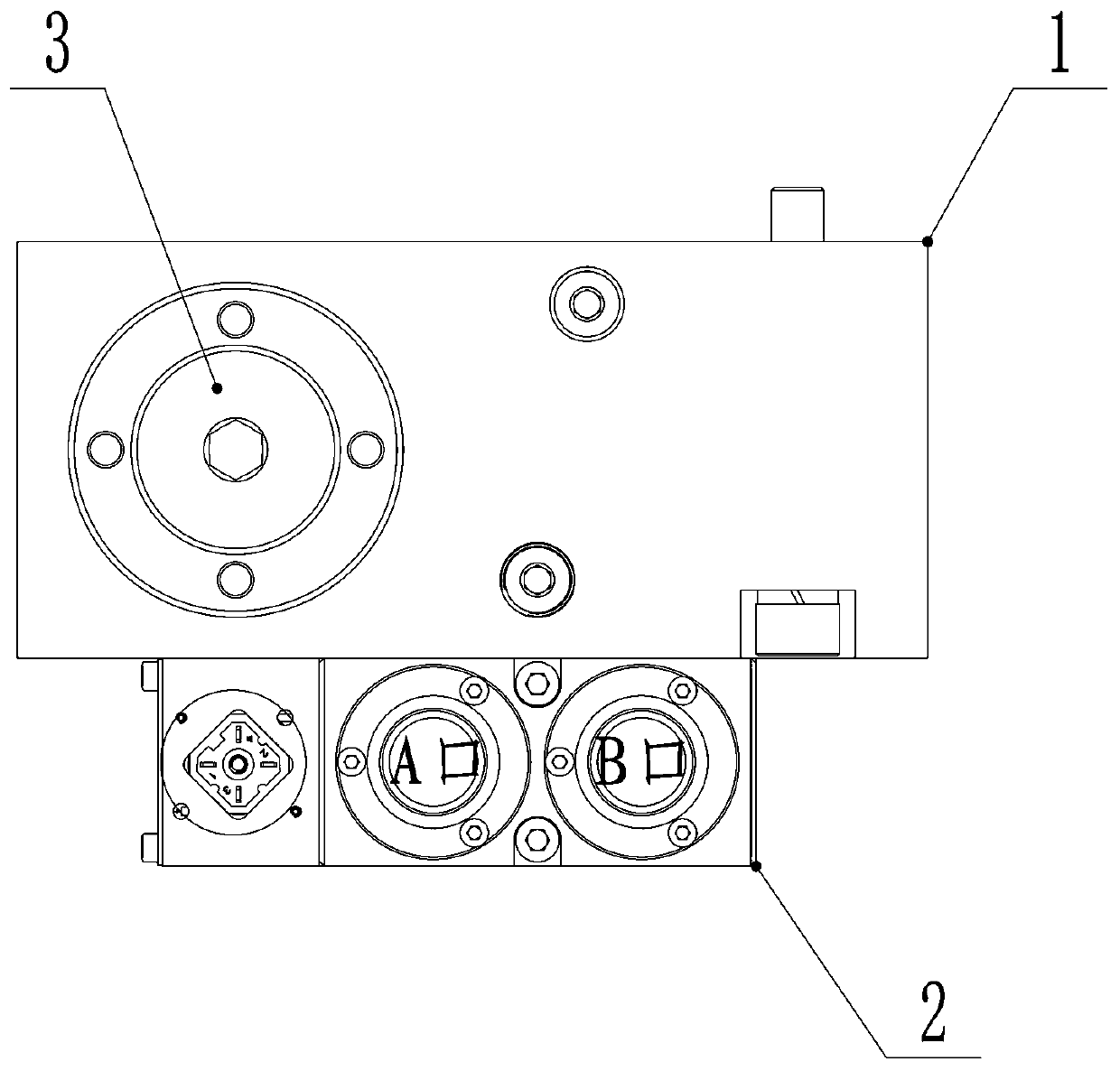

[0031] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that a small hydraulic control flow channel 14 is set in the main valve body 1, and a small flow hydraulic control flow channel 14 is set in the hydraulic control small flow channel 14 One-way valve string 15, the two ends of the hydraulically controlled fine flow channel 14 are respectively connected to the liquid inlet flow channel 11 and the liquid outlet flow channel 12, and the second control oil outlet of the electromagnetic pilot valve 2 ( which is Figure 4 Port A in the middle) communicates with the hydraulic control port of the small flow hydraulic control check valve string 15; the electromagnetic pilot valve 2 itself has two control oil outlets ( Figure 4A port and B port in the middle), can control the two hydraulic control components separately, the original hydraulic control check valve string 3 uses port B, and the small flow hydraulic control check valve string 15 c...

Embodiment 3

[0034] Such as Figure 7 As shown, an electro-hydraulic multi-speed control system includes a liquid inlet main pipe 6, a liquid outlet main pipe 7, an electro-hydraulic main control valve 8 and a hydraulic actuator 9, and the liquid inlet main pipe 6 communicates with the electro-hydraulic main control valve 8 The main oil inlet, the liquid outlet main pipe 7 is connected to the main oil outlet of the electro-hydraulic main control valve 8, the electro-hydraulic main control valve 8 controls the execution action of the hydraulic actuator 9, and the hydraulic actuator 9 Specifically, it can be a jack, a hydraulic support column, an oil cylinder, etc. The above-mentioned equipment is a commonly used control circuit in the existing downhole hydraulic system, and no creative labor is required to obtain it.

[0035] In order to improve the control accuracy and durability of the hydraulic actuator 9, the electro-hydraulic multi-speed buffer valve 10 in the aforementioned embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com