Optical fiber F-P/FBG composite cavity current and temperature synchronous measurement system

A technology of synchronous measurement and composite cavity, which is applied in the field of sensing and measurement, can solve problems such as damage and repeated use of optical fibers, and achieve the effect of eliminating measurement errors and realizing temperature self-compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

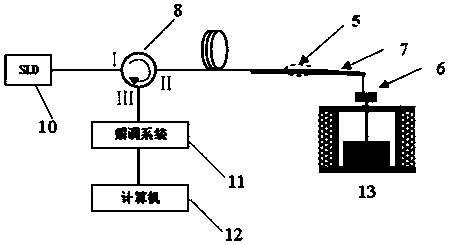

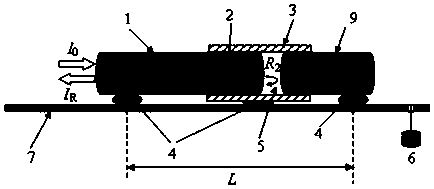

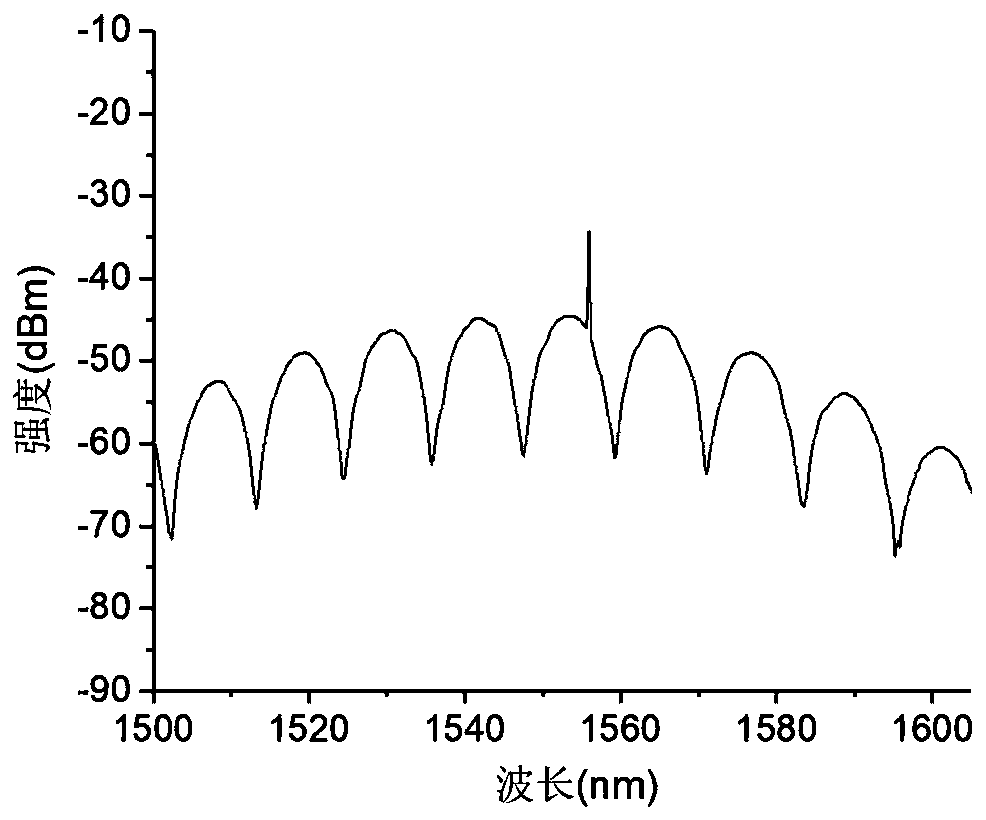

[0020] The invention provides an optical fiber F-P / FBG composite cavity current and temperature synchronous measurement system, such as figure 1 As shown, it uses the optical fiber F-P / FBG composite cavity as the sensing element, the magnetic field generating device generates a magnetic field under the action of the current, and the magnet suspended at one end of the strain gauge bonded to the optical fiber F-P / FBG composite cavity is attracted by the magnetic field, and the optical fiber F-P / FBG The cavity length of the FBG composite cavity changes under the force of the magnet. By measuring the cavity length change of the fiber F-P / FBG composite cavity, the relationship between the measured current and the cavity length is established. In addition, the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com