Optimal parameter determination method for researching oil storage tank hot oil spraying heating process

A heating process and optimal parameter technology, applied in genetic rules, data processing applications, design optimization/simulation, etc., can solve problems such as difficult selection of process parameters, achieve the effect of improving calculation efficiency and ensuring calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

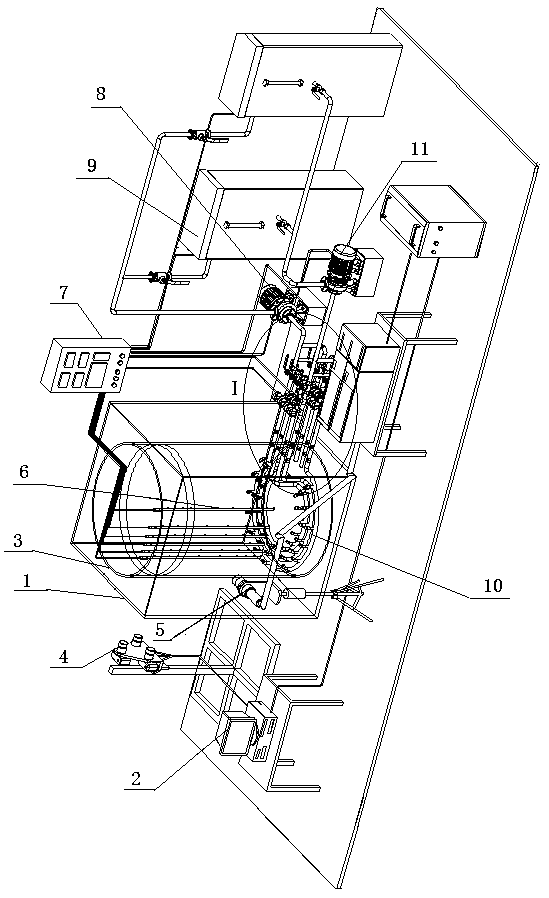

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

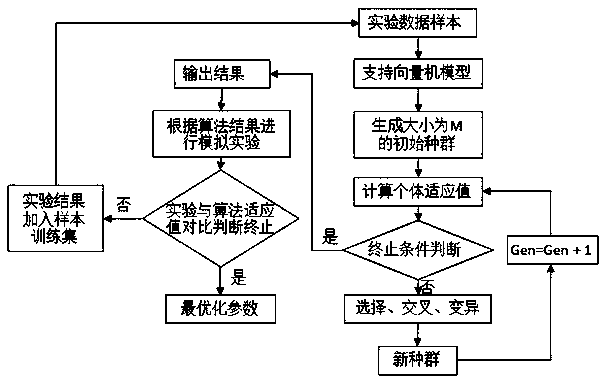

[0031] Such as figure 1 As shown, this method involves the optimization of the process parameters of the hot oil spraying and heating process of the oil storage tank, which greatly improves the computational efficiency. The calculation accuracy is guaranteed.

[0032] According to the factors that affect the heating effect of hot oil spraying in the oil storage tank in the actual production process, the temperature of the spraying medium, the flow rate of the spraying medium, the diameter of the heating nozzle and the angle of the elbow connected to the heating nozzle are the decision variables.

[0033] The experimental scheme is shown in Table 1:

[0034] Table 1 Experimental scheme table

[0035]

[0036] Obtain the measured data of the hot oil spraying heating process in the experimental tank under different parameters, use the field synergy angle, uniformity, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com