Method for judging causes of transverse cracks at corners of slab surface

A judgment method and a technology of transverse cracks, which are applied in the field of iron and steel metallurgy, can solve problems such as difficult to achieve, and achieve the effects of cost saving, simple judgment method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

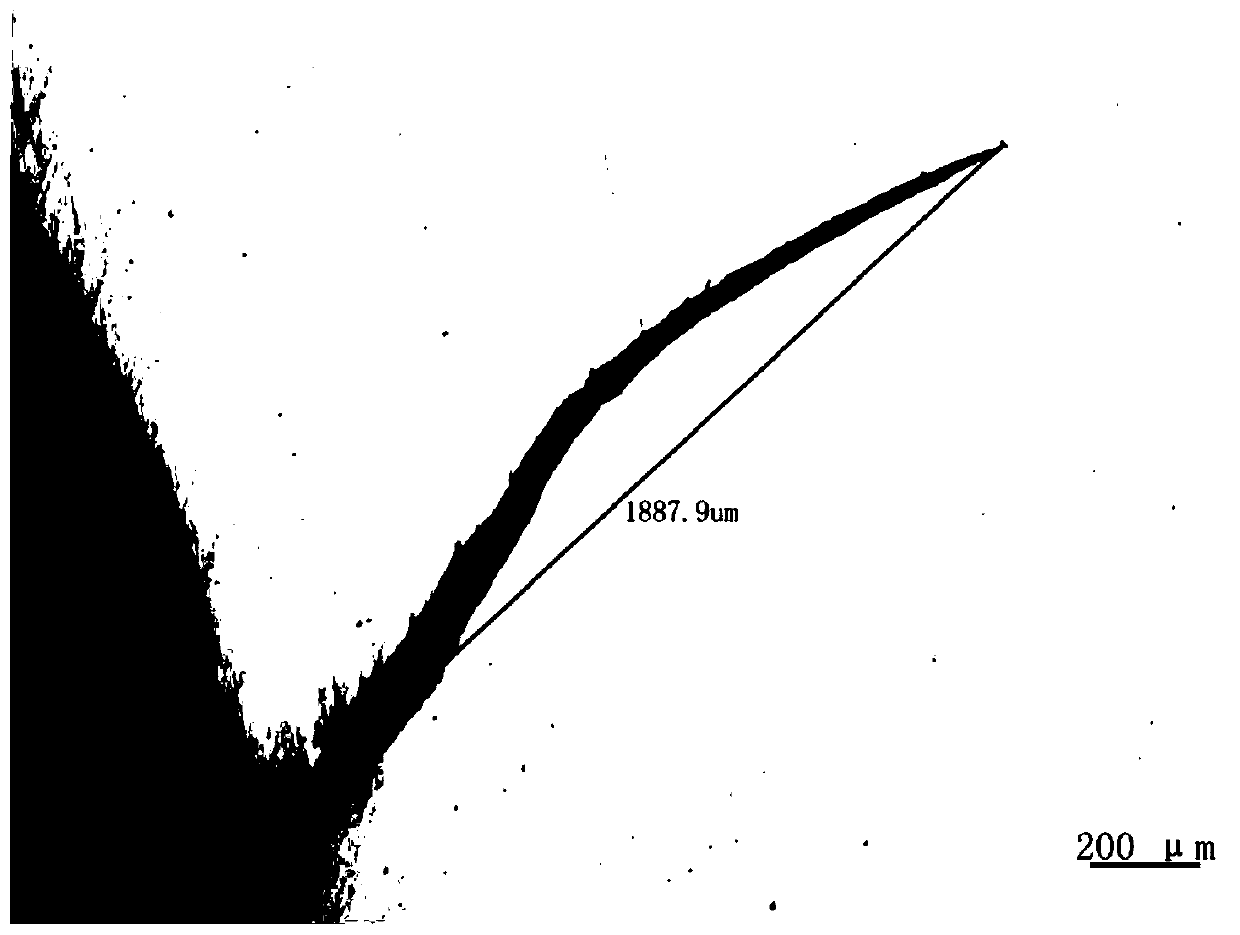

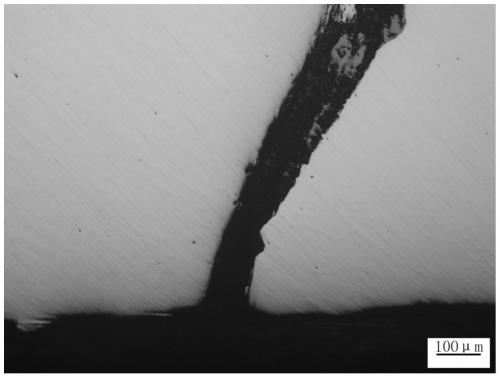

Embodiment 1

[0025] The steel type is SS400B, and the corner transverse crack defects on the surface of the slab are taken, and the sample is processed into 20mm×20mm×20mm, and the sample is ground with sandpaper, polishing cloth, etc. to the extent that it can be observed by a metallographic microscope. Corner cracks appear in the vibration mark valleys at the corners. The widest corner cracks are 200 μm and the longest is 5 mm. A total of 4 cracks were observed, as figure 1 and 2 As shown; the microstructure at the corner crack was observed by metallographic corrosion, there was no decarburization layer, no inclusions, the grain size was normal, the same as the grain size at the matrix, and the main components inside the crack were Fe, Na, Si , Mg, Ca, O, for iron oxide and mold flux. During the production of this furnace, the constant casting speed was guaranteed to be 1.3m / min, the liquid level of the crystallizer fluctuated normally, the superheat was 27°C, the billet section was 125...

Embodiment 2

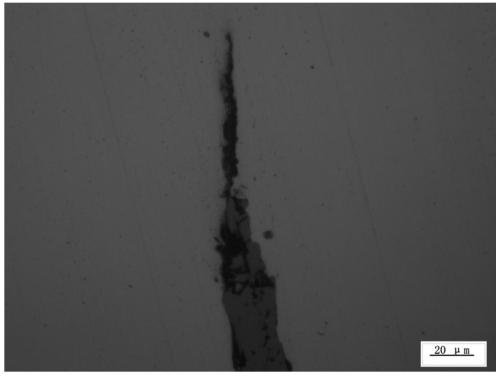

[0027] The steel type is L245M, and the corner transverse crack defects on the surface of the slab are taken, and the sample is processed into 20mm×20mm×20mm, and the sample is ground to the degree that can be observed by a metallographic microscope with sandpaper, polishing cloth, etc. The crack width at the corner is 20-100μm, and the length is less than 2mm. A total of 15 cracks were observed, such as image 3 and 4 As shown; the microstructure at the corner crack was observed by metallographic corrosion, no decarburization layer, no inclusions, normal grain size, the same as the grain size at the matrix, and the main component of the outer and inner cracks are Fe , O, is iron oxide. During the production of this furnace, the constant casting speed was guaranteed to be 1m / min, the crystallizer liquid level fluctuated normally, the degree of superheat was 29°C, the billet cross-section was 1650mm×230mm, which met the requirements of the operating regulations, and the chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com