A cold isostatic graphite forming mold blanking auxiliary device and its use method

A technology for auxiliary devices and forming molds, which is applied to presses, manufacturing tools, etc., can solve the problem of uneven charging of cold isostatic pressing, and achieve the effect of improving the pass rate and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

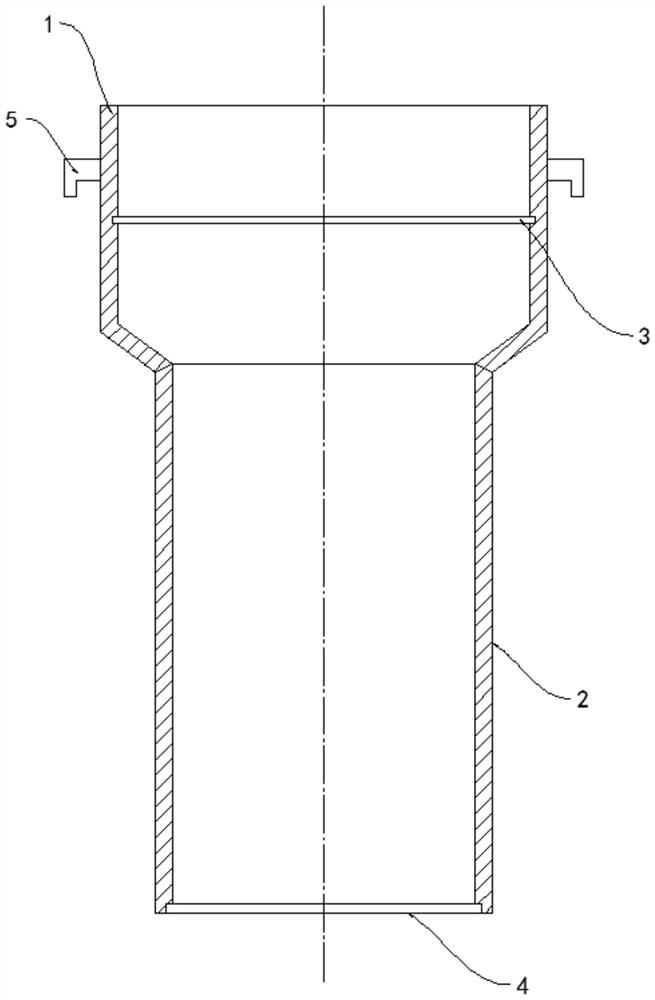

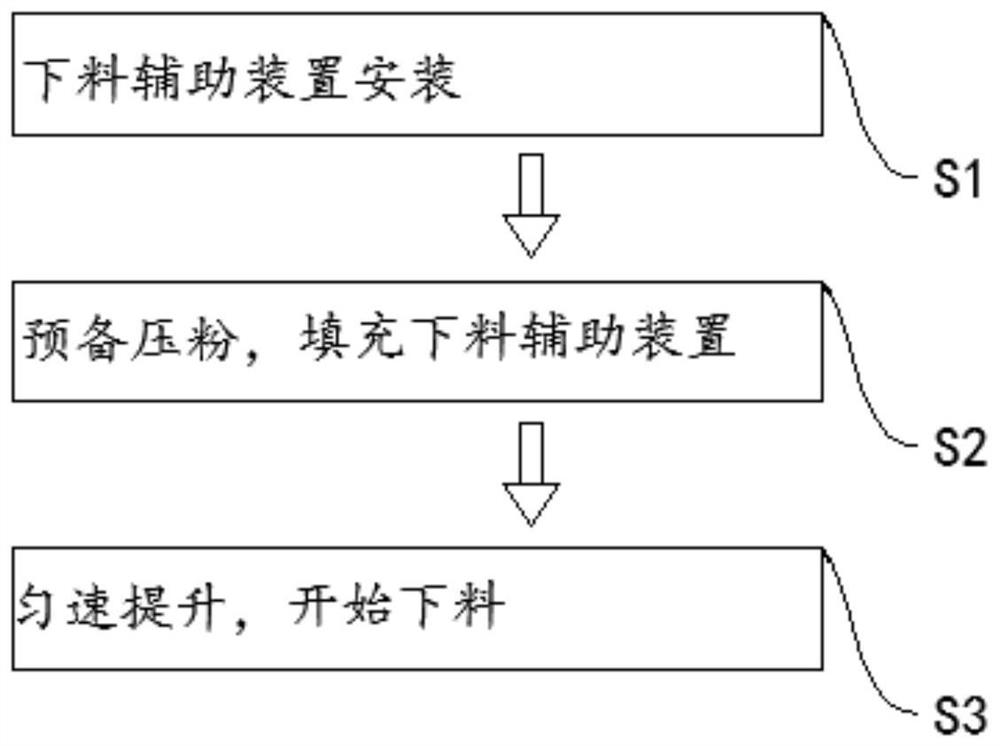

[0038] A cold isostatic graphite molding mold blanking auxiliary device provided by a preferred embodiment of the present invention includes an upper barrel body 1 and a lower barrel body 2 connected up and down, and the inner diameter of the upper barrel body 1 is greater than that of the lower barrel body 2 Inner diameter, the upper barrel body 1 is provided with a blanking buffer net 3, the bottom of the lower barrel body 2 is provided with a secondary cloth screen 4, and the pressed powder in the cold isostatic graphite forming mold material auxiliary device Through the secondary distribution screen 4 at the bottom of the lower barrel body 2, it is evenly dispersed into the molding die. The upper barrel body 1 and the lower barrel body 2 are integrally formed and processed. A plurality of lifting lugs 5 are evenly distributed on the outer side of the upper bucket body 1 . The mesh number of the secondary distribution screen 4 is 20-40 mesh. The effect of the secondary di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com