A kind of retarding type composite water reducer for refractory castable containing silica fume and preparation method thereof

A technology of refractory castables and composite water reducers, applied in the field of refractory castables, can solve the problems of castable construction time (short initial setting time, frequent occurrence of castable construction problems, high-temperature performance damage of castables, etc.), and achieve significant reduction Water efficiency, strong applicability, and high water reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

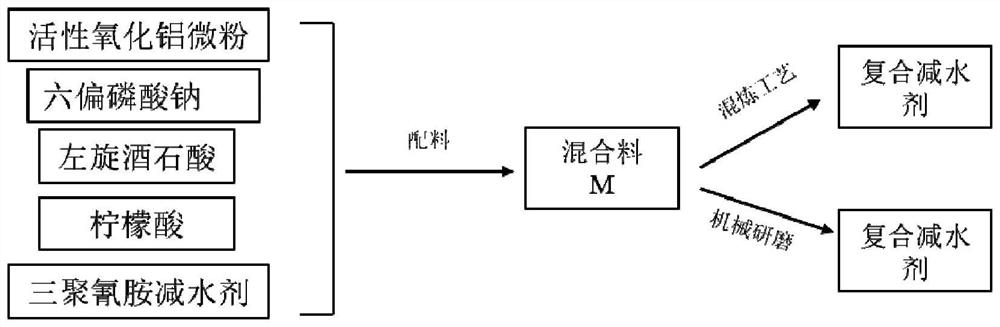

Method used

Image

Examples

Embodiment 1

[0037] Activated alumina powder (Al 2 O 3 Content = 99.4%, BET = 3.1m 2 / g, water content=0.12%, Luoyang Lier Functional Materials Co., Ltd.), sodium hexametaphosphate (pH=6.3, total phosphate (with P 2 O 5 total) content = 69%, inactive phosphate (in P 2 O 5 total) content = 7.3%, water insoluble content = 0.01%, Wuhan Liande Chemical Co., Ltd.), melamine (pH value = 8.1, water content = 4.3%, Cl - Content = 0.3%, powder, Jiangsu Zhaojia Building Materials Technology Co., Ltd.), anhydrous citric acid (purity = 98.2%, powder, Weifang Yingxuan Industrial Co., Ltd.), tartaric acid (left-handed, purity = 95.3%, Hubei Hengjing Rui Chemical Co., Ltd.) according to the mass ratio of 50:13:25:6:6 to make the mixture M1-1; Type), the mixing speed was set to 90 rpm, and the mixing time was 20 minutes to prepare a well-mixed retarded composite water-reducing agent.

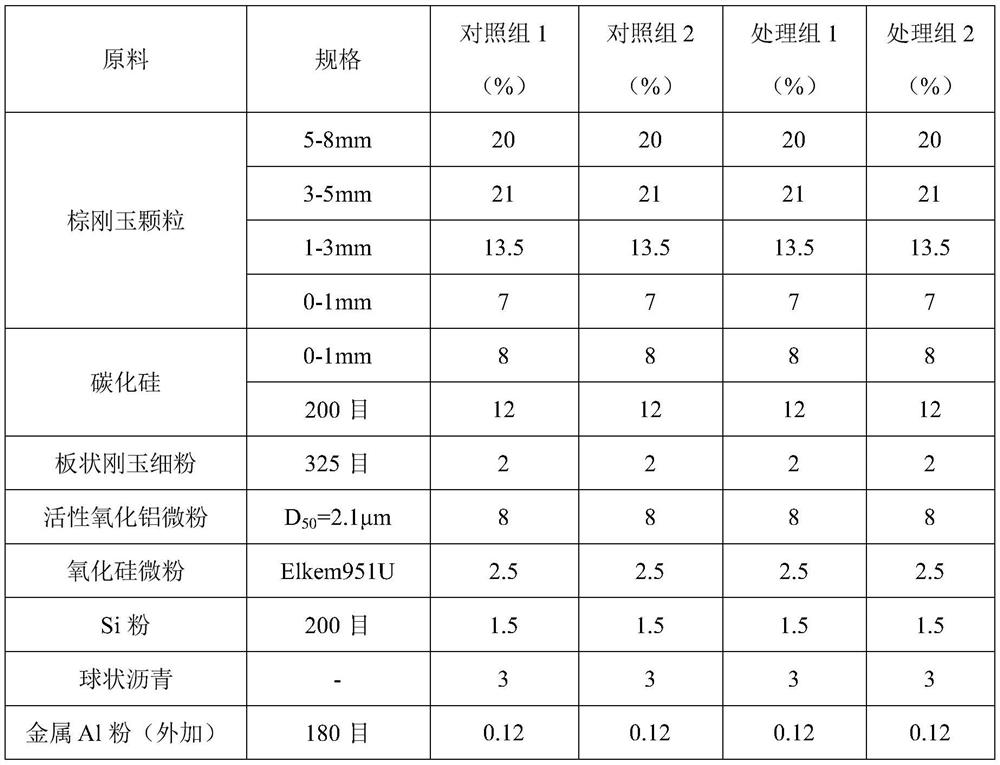

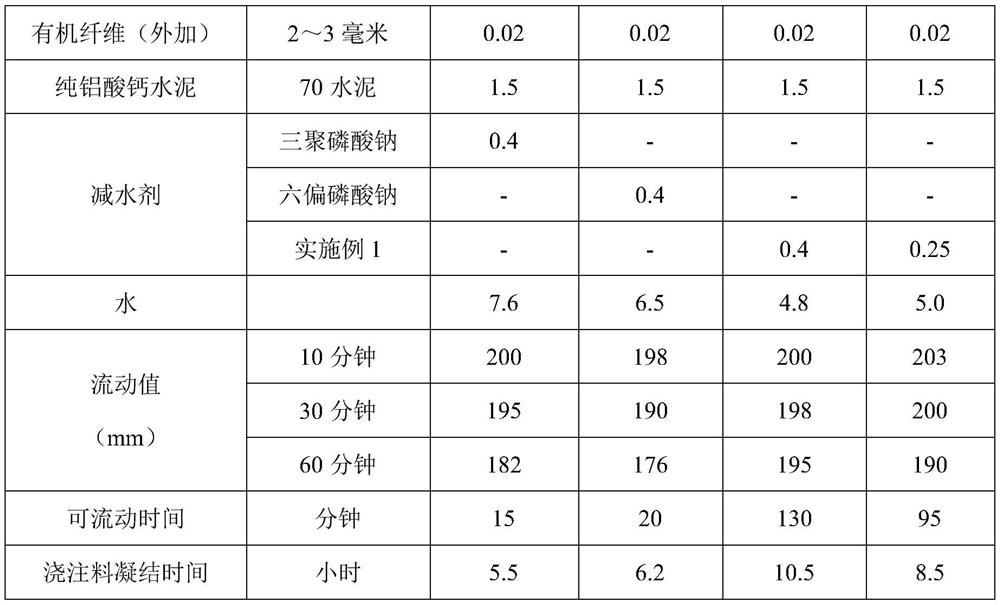

[0038] The retarding type composite water-reducing agent of this embodiment is used as the raw material for prepar...

Embodiment 2

[0045] Activated alumina micropowder (same as Example 1), sodium hexametaphosphate (same as Example 1), melamine (same as Example 1), anhydrous citric acid (same as Example 1), tartaric acid (same as Example 1) according to quality The ratio of 50: 13: 25: 5: 4 was mixed to obtain the mixture M1-2; then, the M1-2 mixture was placed in a high-performance mixer (EIRICH brand, RV24 type), and the mixing speed was set The mixing time is 100 rpm, and the mixing time is 20 minutes to prepare a well-mixed composite water-reducing agent.

[0046]Investigate the performance of the castable containing the composite water-reducing agent of this example under high temperature conditions with reference to Example 1: under the condition of 35 ° C, when the addition of the water-reducing agent is 0.4%, the water addition of the castable is 4.6%, and the construction time is 115 minutes, the overall construction performance is good.

Embodiment 3

[0048] Activated alumina micropowder (same as Example 1), sodium hexametaphosphate (same as Example 1), melamine (same as Example 1), anhydrous citric acid (same as Example 1), tartaric acid (same as Example 1) according to quality The ratio of 50: 10: 30: 6: 4 was mixed to obtain the mixture M1-3; the M1-3 mixture was placed in a high-performance mixer (EIRICH brand, RV24 type), and the mixing speed was set to 100 rev / min, and the mixing time is 20 minutes to prepare a compound water reducing agent that is mixed evenly.

[0049] Investigate the performance of the castable containing the composite water-reducing agent of this embodiment under high temperature conditions with reference to Example 1: under the condition of 35 ° C, when the addition of the water-reducing agent is 0.4%, the water addition of the castable is 4.2%, and the construction time is 105 minutes, the overall construction performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com