Concrete additive and preparation method thereof

An additive and concrete technology, applied in the field of building materials, can solve the problems of poor strength durability and impermeability, complicated preparation process and high preparation cost, achieve remarkable durability and impermeability, simple and easy to operate preparation process, improve Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

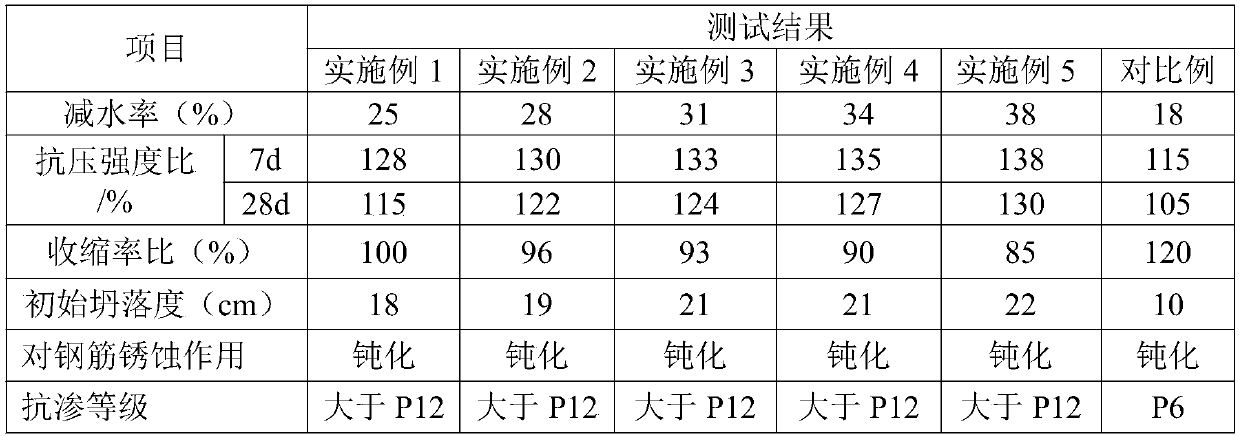

Examples

Embodiment 1

[0028] A concrete additive, comprising the following components in parts by weight: 5 parts of polyurethane modified fly ash, 20 parts of indolylsulfonic acid benzophenone polyphenylene ether, polyethylene glycol monomethyl ether-2000-20 10 parts of octaalkylphosphatidylethanolamine, 10 parts of pentaerythritol, and 10 parts of deionized water.

[0029] The preparation method of the polyurethane modified fly ash comprises the following steps: dispersing 30 g of the fly ash in 100 g of dimethyl sulfoxide, then adding 10 g of polyurethane and 3 g of dibutyltin dilaurate therein, and stirring and reacting at 80°C After 6 hours, filter with suction, wash with ethanol for 3 times, and then dry in a vacuum oven at 75° C. for 10 hours to obtain polyurethane-modified fly ash.

[0030] The preparation method of described indolylsulfonic acid benzophenone polyphenylene ether comprises the steps:

[0031] 1 Under a nitrogen atmosphere, 15.2 g of N-(4-sulfonic acid butyl)-4-(4-(4-(dipent...

Embodiment 2

[0035] A concrete additive, comprising the following components in parts by weight: 7 parts of polyurethane modified fly ash, 22 parts of indolylsulfonic acid benzophenone polyphenylene ether, polyethylene glycol monomethyl ether-2000-20 12 parts of octaalkylphosphatidylethanolamine, 11 parts of pentaerythritol, and 12 parts of deionized water.

[0036] The preparation method of the polyurethane-modified fly ash comprises the following steps: dispersing 35 g of the fly ash in 115 g of N,N-dimethylformamide, then adding 10 g of polyurethane and 3 g of stannous octoate to it, and heating at 82° C. Stir and react for 6.5 hours, then filter with suction, wash with ethanol for 4 times, and then dry in a vacuum oven at 77°C for 11 hours to obtain polyurethane modified fly ash.

[0037] The preparation method of described indolylsulfonic acid benzophenone polyphenylene ether comprises the steps:

[0038] Ⅰ Under a helium atmosphere, mix 15.2 g of N-(4-sulfonic acid butyl)-4-(4-(4-(d...

Embodiment 3

[0042] A concrete additive, comprising the following components in parts by weight: 8 parts of polyurethane modified fly ash, 25 parts of indolylsulfonic acid benzophenone polyphenylene ether, polyethylene glycol monomethyl ether-2000-20 13 parts of octaalkylphosphatidylethanolamine, 13 parts of pentaerythritol, and 12 parts of deionized water.

[0043] The preparation method of the polyurethane modified fly ash comprises the following steps: dispersing 40 g of the fly ash in 125 g of N-methylpyrrolidone, then adding 10 g of polyurethane and 3 g of dioctyltin diacetate to it, and stirring and reacting at 85° C. After 7 hours, filter with suction, wash with ethanol for 4 times, and then dry in a vacuum oven at 79° C. for 13 hours to obtain polyurethane modified fly ash.

[0044] The preparation method of described indolylsulfonic acid benzophenone polyphenylene ether comprises the steps:

[0045] ⅠUnder neon gas atmosphere, mix 15.2g of N-(4-sulfonic acid butyl)-4-(4-(4-(dipen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com