A high-efficiency water reducer for high-strength concrete

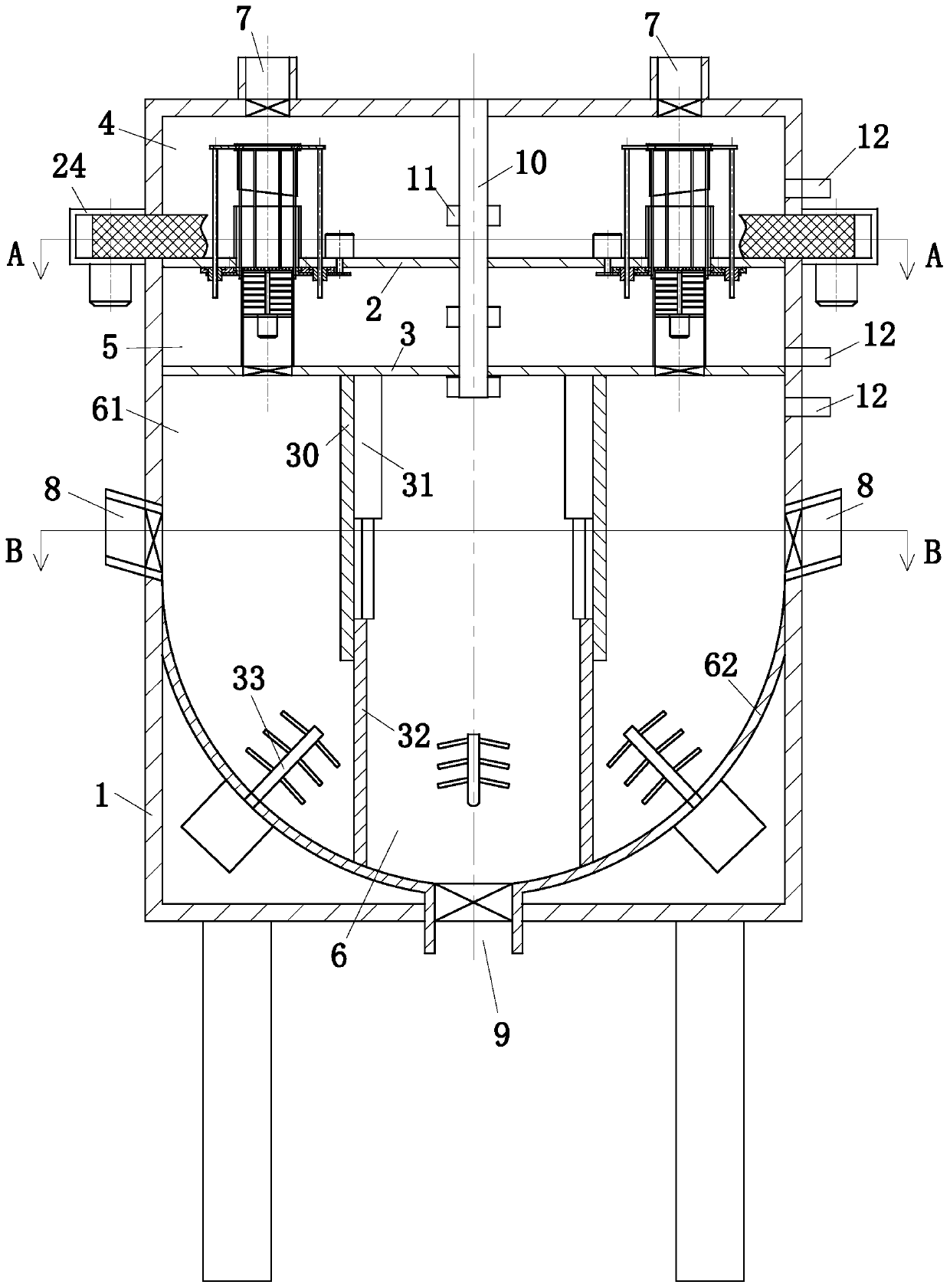

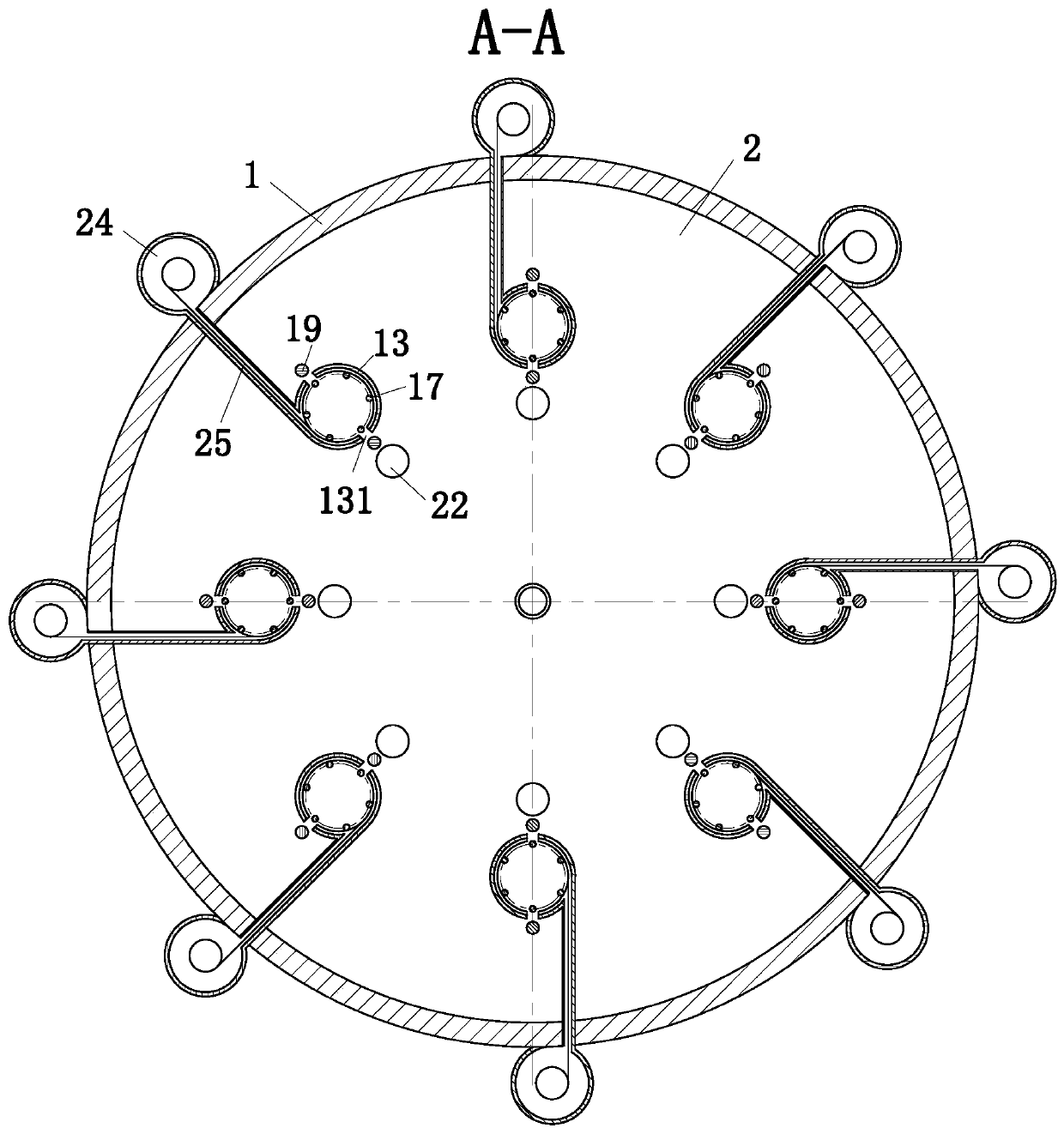

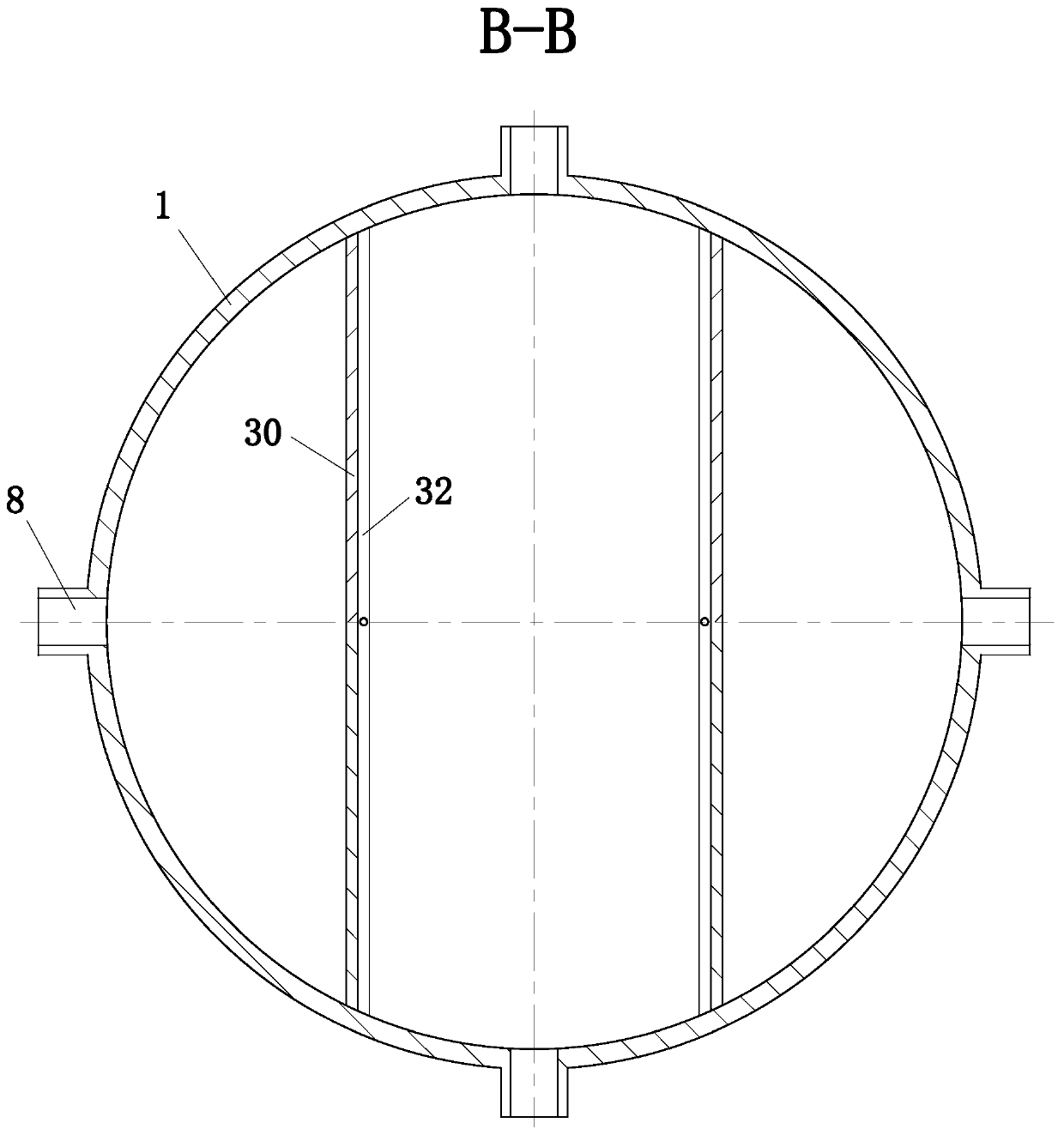

A high-efficiency water reducer and high-strength concrete technology, which is applied to high-efficiency water reducers; special equipment for preparing the high-efficiency water reducer, pressure mixing vessels, and the field of preparation of high-efficiency water reducers can solve the problem of low water-reducing rate and flow Problems such as poor sex and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A high-efficiency water reducer for high-strength concrete, consisting of the following raw materials in parts by weight: 3 parts of decaglyceryl myristate, 8 parts of sodium tripolyphosphate, 3 parts of sodium polyacrylate, dodecylbenzenesulfonic acid 7 parts of sodium, 11 parts of polymaleic acid (HPMA), 6 parts of zinc salt, 5 parts of maltodextrin, 8 parts of N,N'-dinitrosopentamethylenetetramine, 8 parts of azodicarbonamide , 3 parts of N,N-dimethylcyclohexylamine, 6 parts of polyacrylamide (PAM), 15 parts of hydroxyethyl cellulose, 12 parts of sodium carboxymethyl cellulose, 14 parts of naphthalenesulfonate formaldehyde condensate and 6 parts of auxiliary agent;

[0060] The auxiliary agent is composed of the following raw materials in parts by weight: 12 parts of 2-ethylhexyl phosphate, 10 parts of octylphenol polyoxyethylene ether, 5 parts of N,N'-ethylene bisstearamide, lignin sulfonate 10 parts of calcium chloride, 8 parts of β-naphthalene sulfonate formaldeh...

Embodiment 2

[0068] Example 2: A high-efficiency water reducer for high-strength concrete, consisting of the following raw materials in parts by weight: 6 parts of decaglyceryl myristate, 7 parts of sodium tripolyphosphate, 2 parts of sodium polyacrylate, dodecane 8 parts of sodium phenylsulfonate, 10 parts of polymaleic acid (HPMA), 6 parts of zinc salt, 5 parts of maltodextrin, 6 parts of N,N'-dinitrosopentamethylenetetramine, azobis 6 parts of formamide, 4 parts of N,N-dimethylcyclohexylamine, 6 parts of polyacrylamide (PAM), 16 parts of hydroxyethyl cellulose, 8 parts of sodium carboxymethyl cellulose, naphthalenesulfonate formaldehyde condensation 14 parts and 5 parts of additives;

[0069] The auxiliary agent is composed of the following raw materials in parts by weight: 12 parts of 2-ethylhexyl phosphate, 9 parts of octylphenol polyoxyethylene ether, 6 parts of N,N'-ethylene bisstearamide, lignin sulfonate 10 parts of calcium chloride, 10 parts of β-naphthalene sulfonate formaldehy...

Embodiment 3

[0078] A high-efficiency water reducer for high-strength concrete, consisting of the following raw materials in parts by weight: 5 parts of decaglyceryl myristate, 6 parts of sodium tripolyphosphate, 4 parts of sodium polyacrylate, dodecylbenzenesulfonic acid 6 parts of sodium, 10 parts of polymaleic acid (HPMA), 4 parts of zinc salt, 8 parts of maltodextrin, 8 parts of N,N'-dinitrosopentamethylenetetramine, 5 parts of azodicarbonamide , 4 parts of N,N-dimethylcyclohexylamine, 6 parts of polyacrylamide (PAM), 15 parts of hydroxyethyl cellulose, 10 parts of sodium carboxymethyl cellulose, 15 parts of naphthalenesulfonate formaldehyde condensate and 4 parts of auxiliary agent;

[0079] The auxiliary agent is composed of the following raw materials in parts by weight: 12 parts of 2-ethylhexyl phosphate, 8 parts of octylphenol polyoxyethylene ether, 5 parts of N,N'-ethylene bisstearamide, lignin sulfonate 10 parts of calcium chloride, 7 parts of β-naphthalene sulfonate formaldehy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

| gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com