Preparation method of underground self-crosslinking acrylamide polymer for deep formation profile control and flooding

An acrylamide and polymer technology, which is applied in the field of preparation of underground self-crosslinking acrylamide polymers, can solve the problems of unstable gel formation, poor deep effective blocking ability, difficult injection, etc., and achieves stable gel formation, The effect of high gel forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an underground self-crosslinking acrylamide polymer for deep formation control and flooding, comprising the following steps:

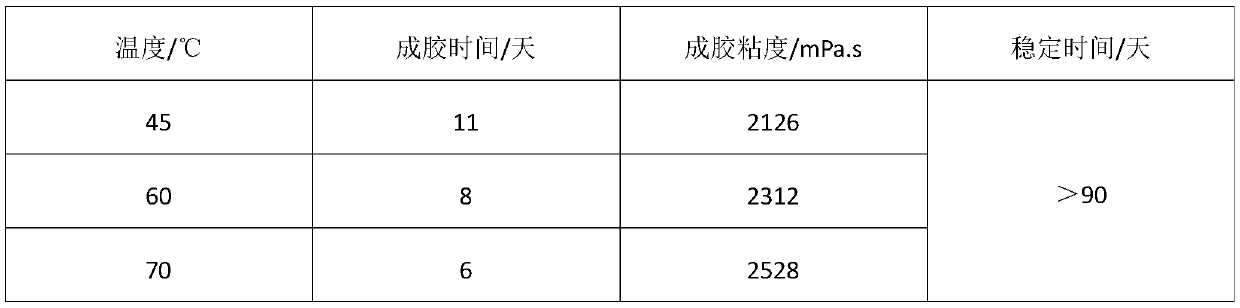

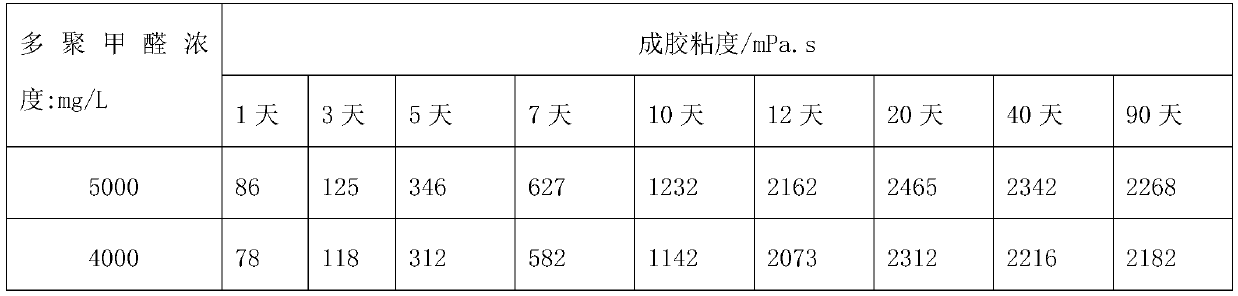

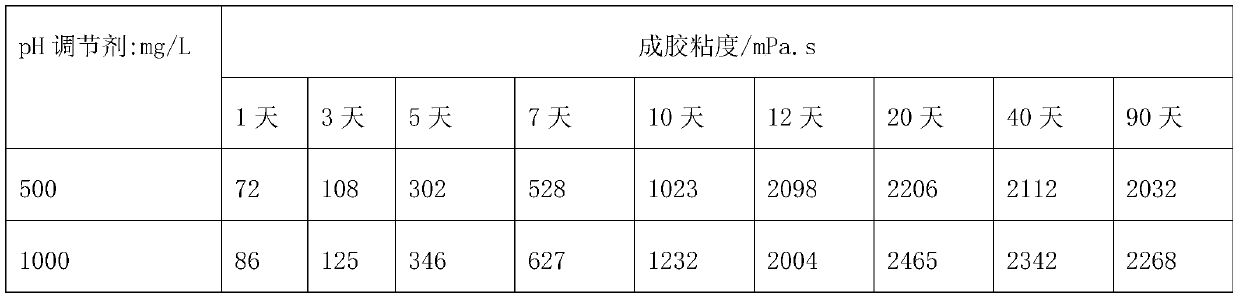

[0033] (1) Take polyacrylamide and add it to water, add sodium hydroxide to adjust the pH, add paraformaldehyde, modify the reaction with paraformaldehyde at room temperature, adjust the pH value to 6 to terminate the reaction, and generate a self-crosslinking functional group The polymer aqueous solution, the mass ratio of polyacrylamide and paraformaldehyde is: 1:1, the mass ratio of polyacrylamide and water is 1:99, the mass ratio of polyacrylamide: sodium hydroxide is: 10:1;

[0034] (2) Transport the polymer aqueous solution with self-crosslinking functional groups to the formation, then add oxalic acid, and carry out intermolecular crosslinking at the applied formation temperature to obtain self-crosslinking acrylamide polymers. The mass ratio of acrylamide is: 2:5.

Embodiment 2

[0036] The preparation method of the underground self-crosslinking type acrylamide polymer used for formation deep regulation and flooding described in Example 1, the difference is:

[0037] Step (1) The mass ratio of polyacrylamide: sodium hydroxide is 10:2.

Embodiment 3

[0039] The preparation method of the underground self-crosslinking type acrylamide polymer used for formation deep regulation and flooding described in Example 1, the difference is:

[0040] Step (1) The mass ratio of polyacrylamide to paraformaldehyde is 5:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com