Flame-retarding rubber floor and preparation method thereof

A flame-retardant rubber and rubber flooring technology, applied in the field of rubber materials, can solve problems such as dust residue and difficulty in cleaning, and achieve the effects of improving product stability, increasing gelation rate, and large friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

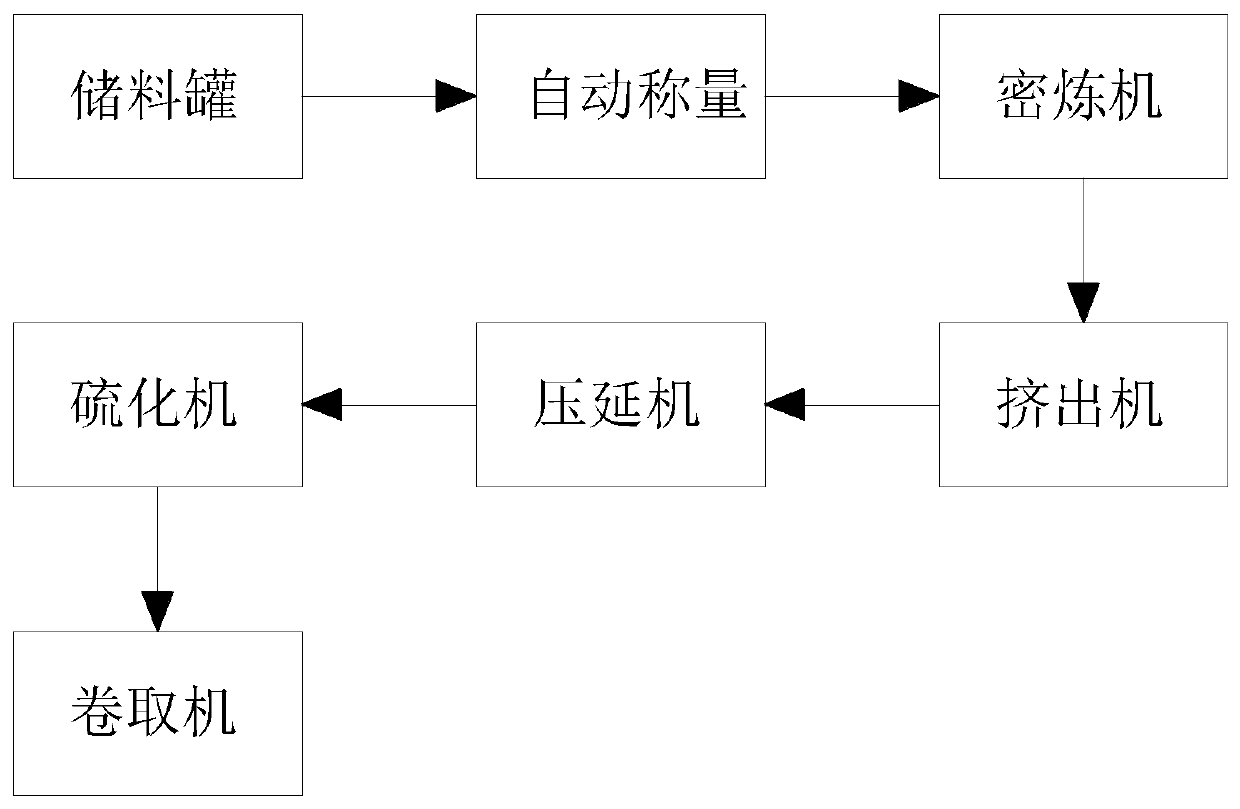

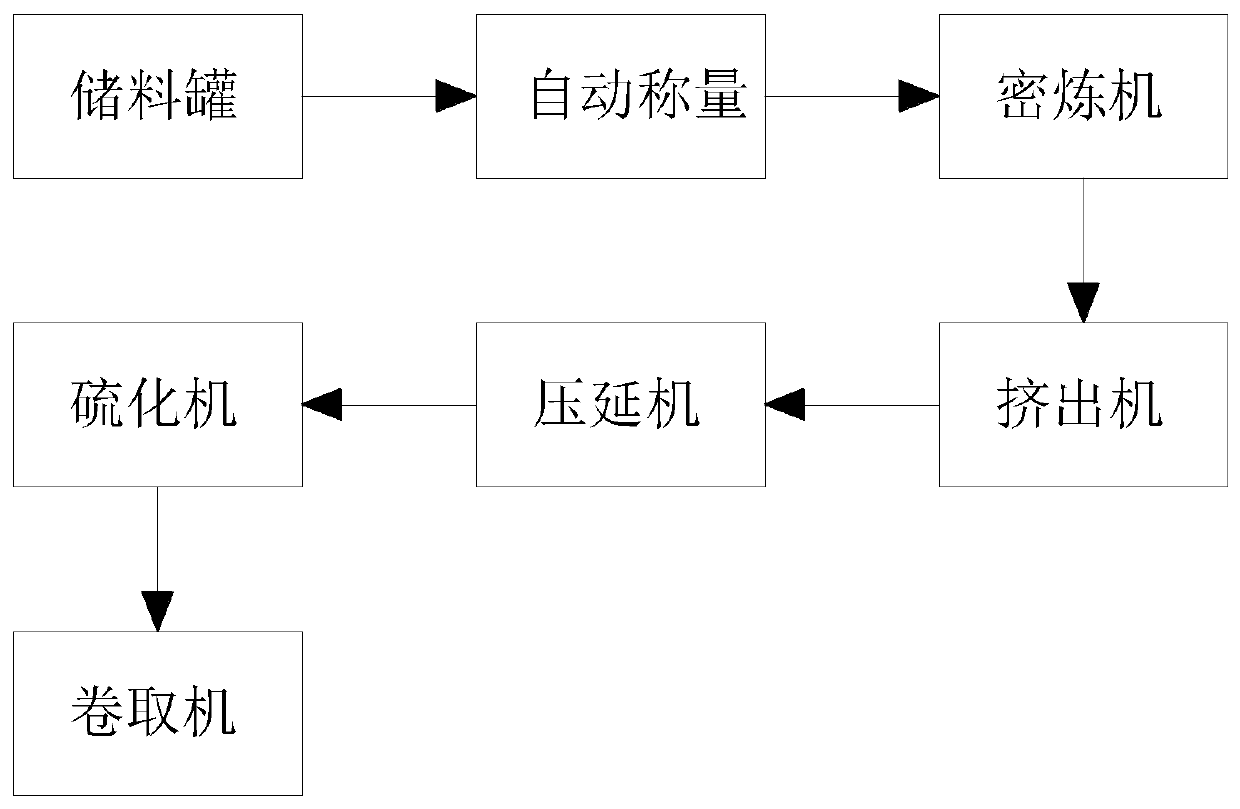

[0034] The embodiment of the present invention also discloses a preparation method for the above-mentioned flame-retardant rubber floor, which is a method of extruding, calendering and vulcanizing at one time after kneading with an internal mixer, specifically including:

[0035] A. Weigh 20-35 parts of ABS resin, 30-50 parts of white carbon black, 40-55 parts of kaolin, 2-4 parts of light stabilizer, 5-8 parts of antioxidant, 40-60 parts of inorganic flame retardant, Mix 10-25 parts of composite flame retardant, 4-8 parts of silane coupling agent, and 2-5 parts of accelerator to form a mixture;

[0036] B. Cool the internal mixer with water, control the temperature of the working room of the internal mixer to 100°C to 150°C, adjust the speed of the internal mixer to 35 rpm, adjust the pressure of the top bolt on the internal mixer to 0.38MPa, and start the mixer for internal mixing. After 10 seconds of internal mixing, weigh 50-70 parts of styrene-butadiene rubber and 20-35 p...

Embodiment 1

[0041] A. Weigh 20 parts of ABS resin, 40 parts of kaolin, 2 parts of light stabilizer, 5 parts of antioxidant, 40 parts of inorganic flame retardant, 10 parts of composite flame retardant, 4 parts of silane coupling agent, and 2 parts of accelerator mixing to form a mixture;

[0042]B. Cool the internal mixer with water, control the temperature of the working room of the internal mixer to 100°C to 150°C, adjust the speed of the internal mixer to 35 rpm, adjust the pressure of the top bolt on the internal mixer to 0.38MPa, and start the mixer for internal mixing. After 10 seconds of internal mixing, weigh 50 parts of styrene-butadiene rubber and 20 parts of natural rubber and add them to the internal mixer to form a mixture, and adjust the speed to 38 rpm;

[0043] C. After 30 seconds for banburying, add the mixed drug into the banbury mixer for banburying;

[0044] D. Add 30 parts of white carbon black at 200 seconds for banburying, control and keep the temperature of the gl...

Embodiment 2

[0047] Compared with Example 1, the present embodiment only changes the formula: the rubber floor includes the following parts by weight: 70 parts of styrene-butadiene rubber, 35 parts of ABS resin, 35 parts of natural rubber, and 50 parts of white carbon black , 55 parts of kaolin, 4 parts of light stabilizer, 8 parts of antioxidant, 60 parts of inorganic flame retardant, 25 parts of composite flame retardant, 8 parts of silane coupling agent, 5 parts of accelerator, 6 parts of vulcanizing agent, preparation method Still adopt the preparation method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com