Construction method for newly adding municipal inspection well in rich water pressure sand and gravel layer

A construction method and technology of sand and pebbles, applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of difficult construction and low safety of newly added inspection wells, achieve the best waterproof effect, easy installation, and quickly change the volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

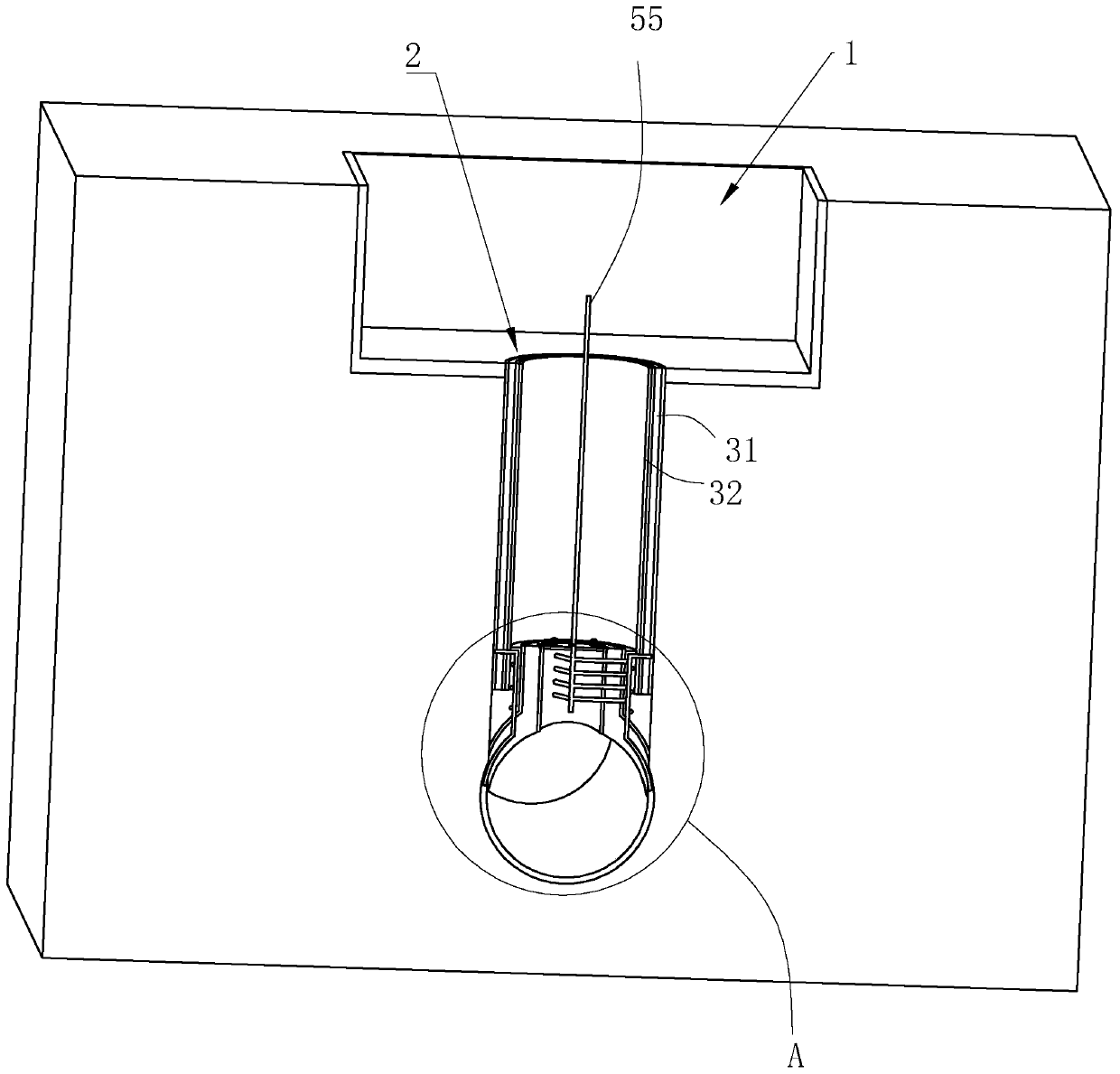

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

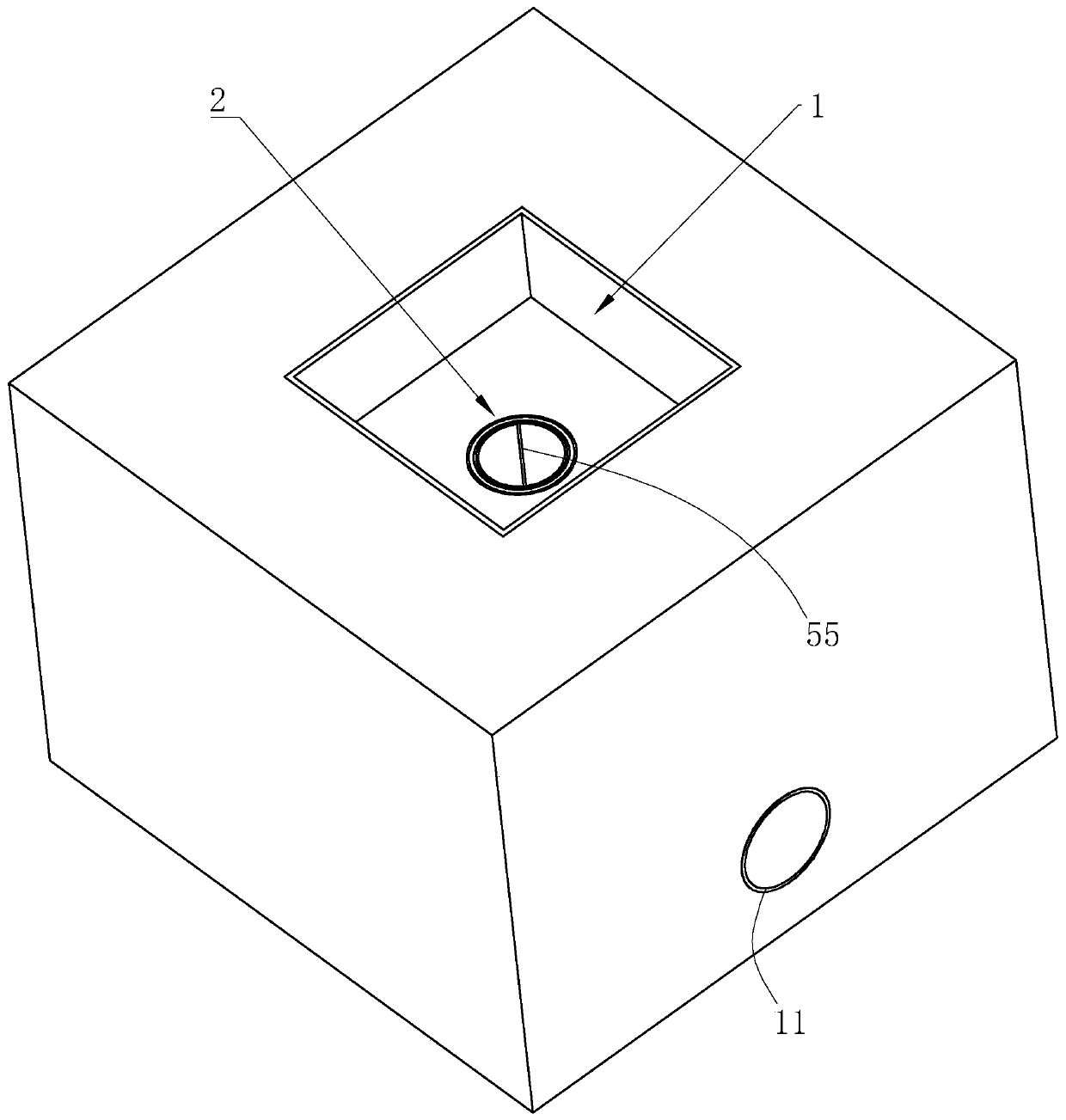

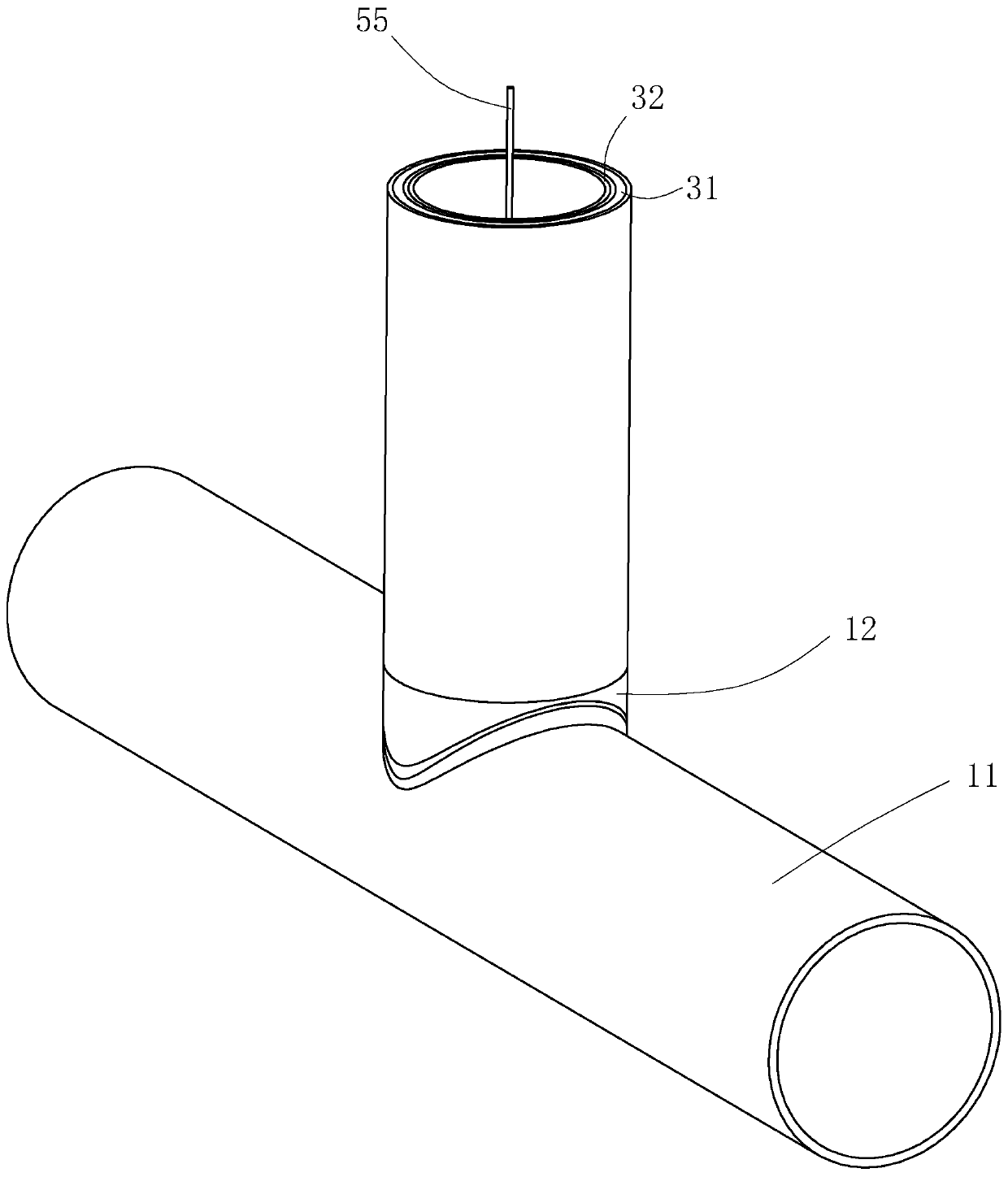

[0043] Such as Figure 1 to Figure 3 As shown in the present invention, a new municipal inspection well construction method disclosed in the water-rich sand and pebble layer includes the following steps:

[0044] Step 1: According to the survey results of the soil layer, the upper cohesive soil layer adopts the "inverted shaft wall method" to support while excavating, and a vertical shaft 1 is formed above the lower water-rich sand and pebble layer;

[0045] Step 2: Drill holes at the bottom of shaft 1 to form channel 2 by means of a percussion drilling rig twice. The first time the hole is formed, the sand and pebble strata are compacted to the periphery. The second time, a drill bit with a slightly larger diameter is used to achieve the purpose of hole expansion. The depth of the hole reaches 1m above the pipeline 11 to be constructed;

[0046] Step 3: Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com