Device internal and external surface integrated imaging method

A technology of internal and external surfaces and imaging methods, applied in the field of imaging, can solve problems such as complex process of machine vision equipment, complex equipment maintenance, and lengthy production cycle, and achieve the effects of reducing the depth of field of the lens, increasing the clarity, and simplifying the complexity of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

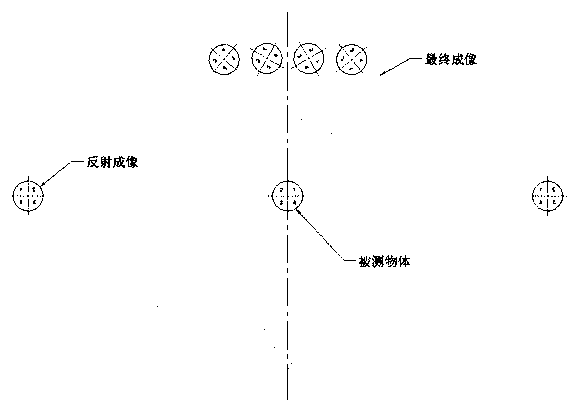

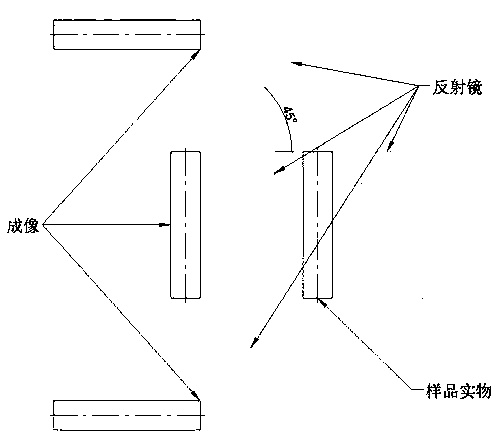

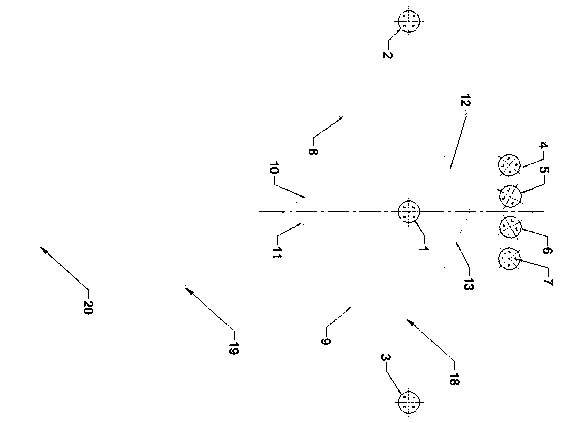

[0038] see Figure 1-5 , the present embodiment provides an integrated imaging method for the inner and outer surfaces of a device, comprising the following steps:

[0039] The first piece 1 is a test sample that can flow horizontally on the production line 18. When the first piece 1 flows from right to left on the production line to the middle of the imaging device, the light source 19 will illuminate the object;

[0040] The eighth piece 8 and the ninth piece 9 are two left and right reflectors, which reflect to form two images of the second image 2 and the third image 3;

[0041] The second image 2 and the third image 3 form the fifth image 5 and the sixth image 6 by the tenth piece 10 and the eleventh piece 11 mirrors;

[0042] The first piece 1 forms the fifth image 5 and the sixth image 6 by the twelfth piece 12 and the thirteenth piece 13;

[0043] The top of the first piece 1 forms the sixteenth image 16 by the fourteenth piece 14, and generates the seventeenth image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com